by Tom Wakeley, 3D Printing Application Engineer

Often companies that are looking to get into the additive manufacturing space come to us with a benchmark file for us to print on the system they are interested in. This can be a great way to see if the machine in question can give you what you are looking for. However, coming in with a realistic expectation of what you are really looking to get is important.

Often, we get files that are not representative of what the company would ultimately be printing. These are parts that have features that are either achievable by other non-comparable technologies or parts that have features that are beyond achievable based on minimum features the manufacturers state the machine is capable of. Unfortunately, they can paint that technology in a bad light.

It would be best to submit a benchmark part that is or is similar to, parts you would expect to be running on the printer in question. Now here comes the tough point for some . . . be open-minded about your design. We do realize that some parts just have to be the way they were designed due to red tape in making changes. etc. But for parts that can be modified, don’t be reluctant to ask for possible changes that could give the benchmark part a chance to be a success. The Applications Engineers that run the machines on a daily basis are trained to know what will and what will not work and have firsthand experience. They can offer suggestions that can help make your part a success.

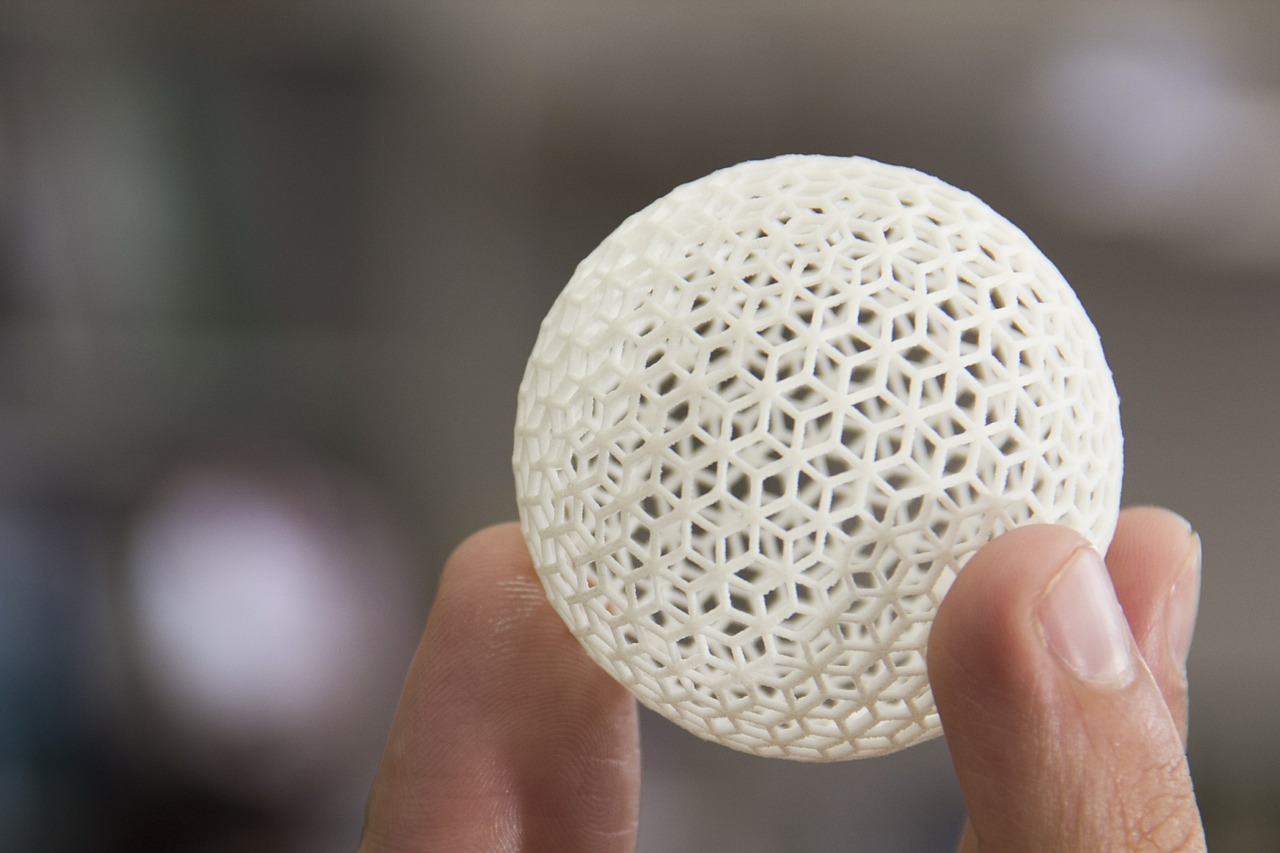

On the flip side there are companies that are really excited to get into additive manufacturing and can be a bit over-zealous. That’s not entirely a bad thing, however, realistic expectations need to be kept. It’s easy to get swept up in all the cool printed things out there with organic designs and meshes and crazy features that can’t be produced another way. I would recommend that you consult the Applications Engineers for ideas that will work for the printer in question. If you are really looking to push the limits of what is possible you might want to wait until you purchase a machine and then do a deep dive into what is possible. Otherwise, you could lose perspective and not give a printer technology a fair shot.

Leave A Comment