KMCA is a model making company based in New Haven, CT. Founded in 1988, they produce models for some of the world’s leading architectural and industrial design firms. Their primary focus is commercial office complexes, however they support a variety of building types ranging from churches to university centers.

KMCA’s traditional methods of production include 3 Axis CNC machining and laser cutting, which operate in conjunction with manual assembly techniques. While these machining methods are advanced and effective, they can also be time consuming and costly. Through conventional methods, there is also a limit to the design freedom, especially for units with complicated geometry. Due to these constraints, KMCA has turned to 3D printing as an additional tool for production.

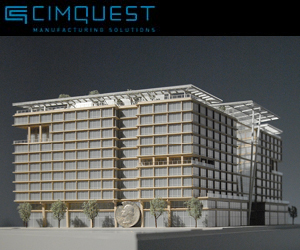

Additive manufacturing was not a completely foreign concept for KMCA. In the past, they’ve outsourced 3D printing for intricate parts that make up the designs of advanced models. However after seeing the exceptional capabilities and opportunities of the technology, they decided to aquire their own Stratasys printers. Since then, the printers have yielded great benefits on numerous projects, including models for a commercial development in the new CityCenter of Washington DC.

KMCA was tasked with fabricating large scale models of 900 New York Avenue at CityCenterDC using traditional stick construction. Skilled craftsmen built these models using tens of thousands of components each. But the developer also wanted a smaller scale model of each building that the sales team could use to motivate prospective tenants to visit the design centers. Ken Champlin, president and founder of KMCA, presented two alternative approaches to building the scaled models.

The first approach was to use stick construction. It would have taken about eight weeks and cost about $20,000 to use this method to build a smaller model. Champlin recommended instead using 3D printing to produce the majority of the model as a single piece. This approach made it possible to provide a high level of detail while eliminating the time and cost involved in producing and assembling most of the individual components. Ken states,“If we were to try and make this in a conventional shop fashion, it would be cost prohibitive. Through 3D printing, we were able to provide a beautiful model at a very reasonable price.”

Since the implementation of 3D Printing, KMCA has experienced immense cost savings which have increased their overall competitiveness. The technology is a great compliment to their traditional methods and they continue to find innovative ways to improve processes.

“The Fortus 250’s have been real workhorses and have enabled us to produce things geometrically that would not be possible in a conventional model shop.The support from Cimquest has been fantastic. They’ve kept us up to speed on all of the new innovations that are being released.”

– Ken Champlin, founder of KMCA

Download the case study pdf by clicking on the image to the left.

To see more customer success stories, please click the button below.

Leave A Comment