Since 1976, Plastinax has been manufacturing eyewear for some of the world’s biggest brands. They work with global customers to design sunglasses, optical frames, and safety frames, then move into high-volume production, injection molding as many as 80,000 to 100,000 frames each month. Lead time and responsiveness are of utmost importance — in order to remain competitive in a global market, Plastinax has to expedite design and manufacturing so that their frames can travel from their base in Mauritius to their customers on every continent.

Plastinax, owned by the ENL Group, uses Formlabs stereolithography (SLA) and selective laser sintering (SLS) 3D printers to produce functional prototypes of frames in low volumes for their customers to evaluate and give feedback on before moving to tooling. They also have expanded into 3D printed tooling for low volume runs and bridge production of eyewear components, using the Fuse 1 SLS 3D printer and Nylon 12 Powder.

The 3D printing workflow has also increased their responsiveness and expanded the range of designs they can produce. Plastinax Design Engineer Steeven Devasagayaum spoke with us about integrating the Form 2 and Fuse 1 into his workflow, and how 3D printing has changed the company’s approach to design and manufacturing.

Large-Scale Manufacturing in Mauritius

Plastinax started manufacturing eyewear frames in the 1970s for big-name brands in the US, Europe, and across the world. Much like other industries at the time, the design process was slower and more hands-on, although even in the early days the industry was focused on creativity and differentiation through complex designs or branding.

When Devasagayaum joined the company in 2006, he helped the team transition from handmade prototypes to outsourced 3D printed models. This new workflow helped get early iteration models closer to the final injection molded product and sped up the design process — they could move from a design brief or technical drawing to a hand-made prototype, then to outsourced 3D scanning and 3D drawing.

The additional step of 3D printed models was helpful in getting prototypes more similar to final run parts but still presented issues if a client requested further changes — an additional set of prototypes could take a week or more to arrive. The extended timeline made it difficult for Plastinax to remain competitive.

Bringing 3D Printing In-House

The Plastinax Research and Development team started looking for an SLA 3D printer to bring in-house and reduce lead times. However, the machines on the market were expensive, and outsourcing rapid prototypes was more cost-effective than investing in the machines available on the market at the time.

In 2016, Plastinax decided to bring 3D printing in-house with a Form 2. A second unit followed a year later to satisfy the increasing demand for rapid prototypes. “Those machines were game changers. I could design and get a rapid prototype in a matter of hours. We could show our reactivity, we could do changes within a week for our international clients. They have the best quality-to-price ratio and above all, are reliable.” says Devasagayaum.

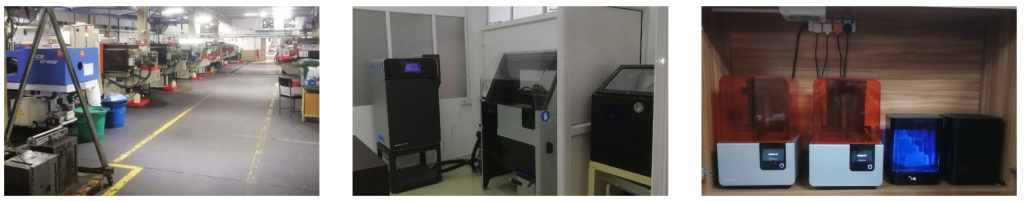

By leveraging the industrial power of a large-scale manufacturing operation (left), Plastinax produces over a million pairs of eyeglasses each year. Adding in-house 3D printers like the Fuse Series (center) and Form 2 (right), enables them to iterate more thoroughly and continue growing their business.

Leave A Comment