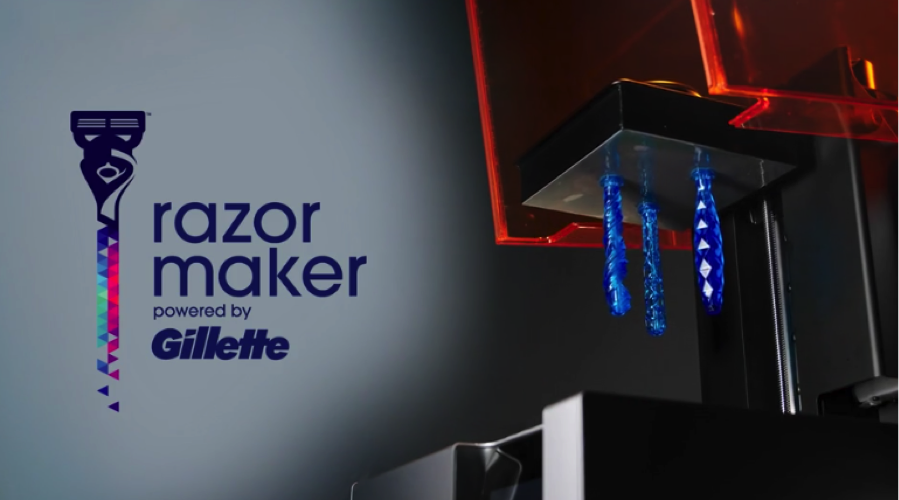

Razor manufacturer Gillette is piloting its Razor Maker™ concept—a platform that serves as one of the first examples of direct-to-consumer, end-use 3D printed parts. Using Formlabs Form 2 3D printers as its production engine, Razor Maker™ gives consumers the power to create and order customized 3D printed razor handles, with the choice of 48 different designs (and counting), a variety of colors, and the option to add custom text.

“Our partnership with Formlabs, and the power of their 3D printers, enable consumers to have a say on how their razors should look. We are excited to work with our Boston neighbors to pilot this breakthrough concept of customization,” said Donato Diez, global brand manager for Gillette and Razor Maker™ co-founder.

Unlocking Design Freedom and the Power of Personalization

The Razor Maker™ concept unleashes design freedom from designer’s desk to final product, and offers a glimpse into the future of mass-customized products.

“Combining our best shaving technology with the power and flexibility of 3D printing opens up a whole new world of product design possibilities,” said Rob Johnson, design engineer and Razor Maker™ co-founder.

With 3D printing, complexity and variety are “free”; a 3D printer takes no more time, energy, or material to manufacture a complex shape than a simple one, and zero tooling means printing a variety of designs requires no extra production costs.

The design freedom unlocked by 3D printing allowed Razor Maker™ designers to draw inspiration from complex geometries found in nature, architecture, and technology.

Designers drew inspiration from geometries found in nature, architecture, and technology to create intricate shapes that would be difficult or impossible to realize through traditional manufacturing.

“It allows us to think about form in a way that was never possible before,” said Rory McGarry, industrial design lead at Razor Maker™. “In a traditional sense, we could only do one or two razor designs a year, whereas now we can have an idea, create it in 3D, print it, look at it, adjust it, and say that’s it.”

With 3D printing, Razor Maker™ designers are able to quickly test ideas, moving seamlessly from concept to 3D model to physical product within days.

Ultimately, the absence of design constraints fuels the ability to offer consumers freedom of choice. In a market saturated by mass-produced goods, the goal of Razor Maker™ is to offer consumers the chance to make razors that are completely their own.

A Workflow for Custom Manufacturing

Pursuing such a high level of customization for Razor Maker™ required the team to completely rethink their approach to manufacturing.

The initial steps in the process are completely digital: a consumer customizes a unique handle through the Razor Maker™ website and the resulting design is converted into a 3D file. Multiple design files are then sent to a 3D printer to be simultaneously printed in a single batch. Each handle is then washed, post-cured, coated, and assembled before being shipped directly to a consumer’s door.

Each Razor Maker handle is printed at Gillette’s Boston headquarters using Form 2 stereolithography (SLA) 3D printers.

Previously, Gillette had only applied 3D printing for prototyping, but advancements in materials and hardware have made the technology a viable options to produce end-use parts.

Ease of customization is an inherent advantage of 3D printing. The technology removes the need for tooling, requiring no up-front investment in molds and eliminating the exponential costs of producing a variety of complex designs. Plus, scaling custom manufacturing can be as easy as adding more printers. Gillette is also experimenting with automating 3D printing production processes, working with Formlabs as one of the first testers of Form Cell, a technology demonstration exploring the future of 3D printing in production environments.

“The Razor Maker™ concept allows us to create a new design, print and test it, and then the next day that design becomes a new handle available on the website,” Johnson said. “That was never possible before.”

For more information on our Formlabs 3D printers, please click the button below.

Leave A Comment