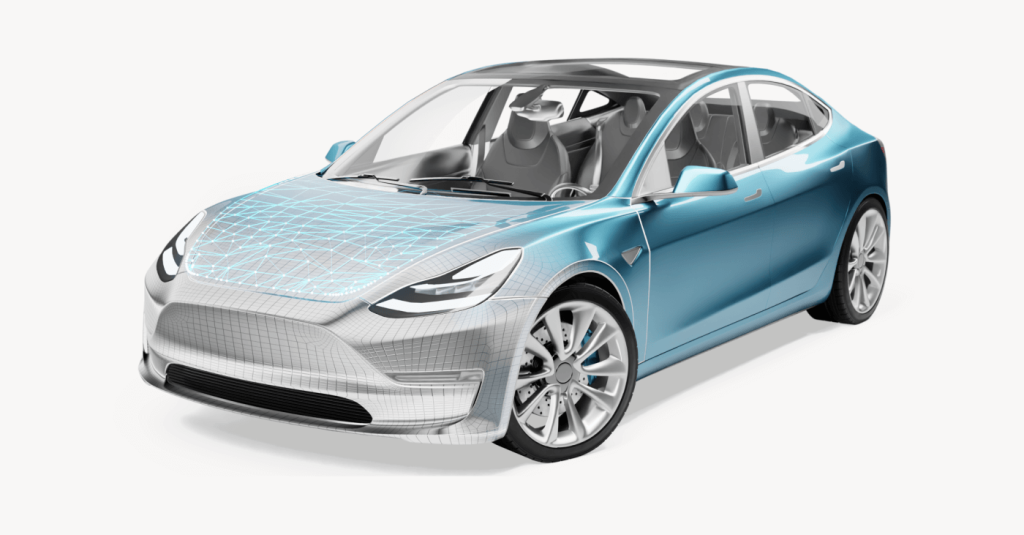

By bridging the gap between the physical and digital worlds, 3D scanning enables automakers to work with high-fidelity digital twins of physical objects within CAD/CAM/CAE environments, allowing for rapid design iteration, measurement automation, enhanced collaboration, and archiving for historical trend analysis. Here are some of the ways that 3D scanning helps the automotive industry.

Reverse engineering

3D scanning is a fast method of creating measurements dense enough on a part to resolve even highly complex surfaces and features, which can be useful for reverse engineering or reconstructing an existing part in CAD. Out-of-production parts or parts designed without CAD (or before CAD) can be scanned and the original design intent can be extracted from the data to generate a new file for future manufacturing.

Quality control and 3D inspection

Quality control is the stage at which the manufactured part is inspected to make sure it meets all of the required specifications for proper performance, such as whether or not a cylinder cover will fit the intended engine exactly as expected. 3D scanning brings a great deal of speed and accuracy to the inspection process, enabling automotive manufacturers to quickly capture a 3D model of a part and compare it to the part’s original design, usually a CAD model.

3D printing

3D printing, also known as additive manufacturing, is used in the automotive industry to quickly produce parts as well as make parts that use lighter, stronger plastics instead of more conventional materials. 3D printing typically requires a 3D model, but in some cases a manufacturer may be able to 3D print a part directly from a 3D scan.

Vehicle customization

Many vehicle owners like to customize their vehicles with parts and accessories that fulfill a wide range of functional and aesthetic purposes. With 3D scanning, aftermarket parts can be made to fit their vehicles with extreme precision. Like a tailored suit, an aftermarket part based on a 3D scan can be designed for a single, specific vehicle, not just a certain make and model. In this way, 3D scanning gives custom parts manufacturers an interesting way to differentiate their offerings.

Design and prototyping

Automotive designers and engineers are often attempting to improve the performance of an existing vehicle part or understand why one isn’t performing as desired. In these cases, 3D scanning can quickly create an accurate, high-resolution 3D model of the part, component, assembly or vehicle as manufactured — as opposed to the original 3D design. With an accurate 3D model of the part, engineers can test out a range of new design ideas in an extremely realistic simulation before actually manufacturing them.

Contact us about how scanning can help you in your industry by clicking below.

Leave A Comment