Architectural glass specialist New Hudson Facades (NHF) is reportedly saving up to $50 thousand per quarter with a new, round-the-clock 3D printing facility. The company has installed a Rize One 3D printer at its office in Pennsylvania to produce custom tooling and fixtures for its large-scale projects.

According to Andrew Black, Engineering Manager at NHF, “I put Rize One right next to my desk, so I can use it all the time. It’s so easy, anyone can use it.”

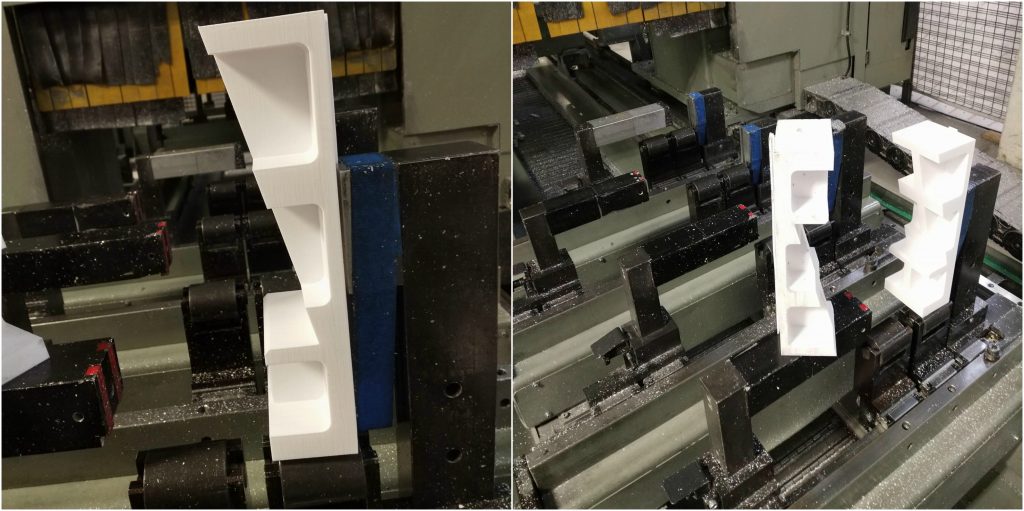

Miscellaneous Rize 3D printed project tooling at NHF. Photos via Rize

Sky’s the limit

Founded in 2014, NHF undertakes the installation of custom aluminum and glass façades for skyscrapers. Its most recent projects include the front of three towers in Hudson Yards, New York, including the striking 35 Hudson Yards with a concave feature wall.

Facade of 35 Hudson Yards, a project by NHF. Photo via New Hudson Façades

On average, each project at NHF relies on the production of between one hundred and two hundred unique fixtures used to help hold aluminum profiles in place, and ensure the perfect fit of the windows. Typically, this tooling would be made using the site’s CNC machines, costing around $200 per part.

As engineering manager, Black sought new ways to reduce the cost of production, and also cut lead times for new ideas to take shape.

Average $50 per part

A Rize One 3D printer was installed at NHF by authorized Rize reseller Cimquest Inc. that recently closed a similar deal with manufacturer of custom metal stamping and industrial tooling HMS Industries, Inc.

In-office, the NHF team can now quickly turn around fixtures at a fraction of the time it would take to machine them – producing an average of 2 unique parts per day.

Instead of $200, the price of each fixture has also been cut to a median of $50. For clamping fixtures alone, this results in a quarterly saving on $50 thousand dollars.

Streamlining the lead time, certain assemblies are 50% shorter, and the quality assurance/control rejection rate of assemblies are expected to drop from 1.5% to 0.5%.

Rize 3D printed fixtures can also be post machined. Photos via Rize

Industrial 3D printing

Tooling, jigs and fixtures has become an award-winning application for 3D printing, unlocking a great deal of value for industrial customers. Keen to provide the best solution for this market, Rize has added Digitally Augmented Parts (DAP) functionality to its technology enabling serialization and, most recently, the company launched its Additive Indirect Supplies Crib with manufacturing optimization specialist Production Services Management, Inc. (PSMI).

For more information on Rize 3D printers, please click the button below.

Leave A Comment