CAD/CAM software is a combination of computer-aided design (CAD) software and computer-aided machining (CAM) software. CAD creates the design geometry and then CAM takes the design intent and produces optimum toolpath strategies to subsequently drive the CNC Machine. Most CAD/CAM systems are machine-independent, which means the user is required to pass the intermediate format (Cutter Location, CL Data) through a post processor to produce the correct G-Code for the selected machine. A CNC post processor is a type of software meant to turn CAM code into a readable CNC code according to which machine will be running the part.

How do post processors work?

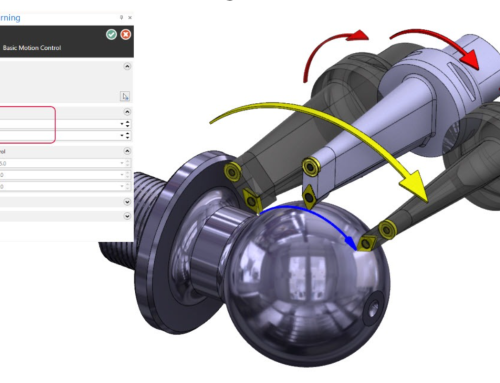

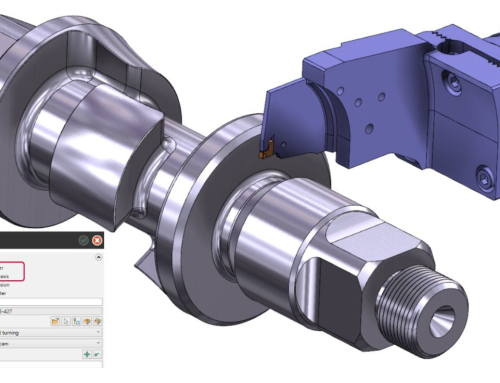

Post processors take into account each individual machine’s kinematics – how the tool or workpiece moves along the linear and rotary axes. This motion data dictates how the post processor should use the original CAM code. The post processor can adjust things like feeds and speeds, transitions between toolpaths, and tool length compensation. The best post processors optimize machining.

What happens during post processing?

Step 1:

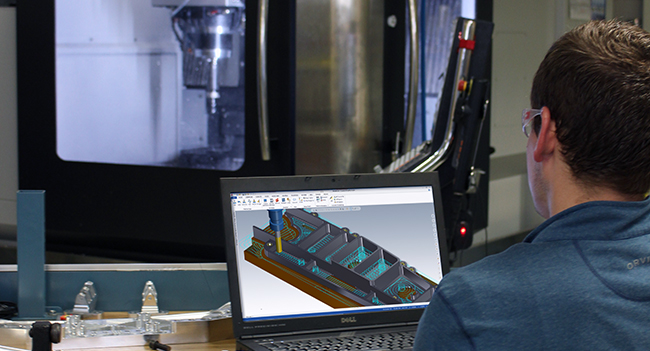

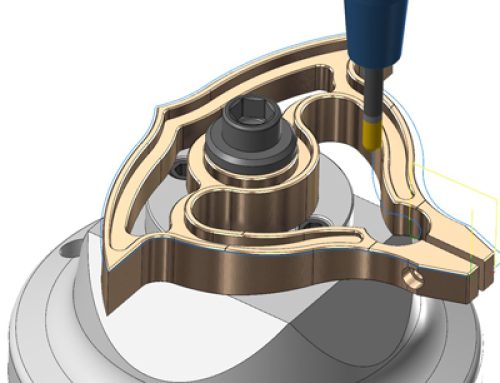

The 3D CAD model is imported into Mastercam.

Step 2:

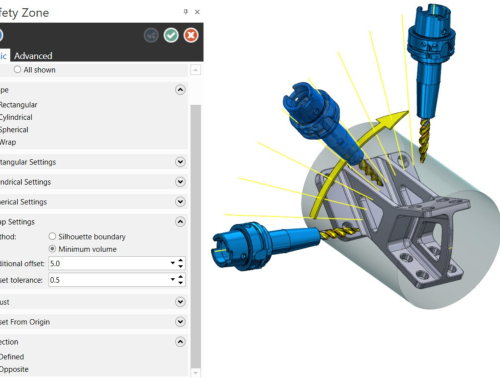

Mastercam is fed information about the machining operations by the CNC programmers. It creates the paths the tools will take.

Step 3:

The post processor converts the toolpath into language that the machine understands. The output produced by the post processor should be usable without any further modifications.

Step 4:

The code is exported to the machine, and the manufacturing process begins.

How do you find the right post processor for your needs?

Mastercam already has a library of prewritten post processors for machine series like the Mazak Mark IV, DMG Mori NT, and the Doosan Puma MX. In addition, Cimquest has an extensive library of post processors. We sell and support posts for Mastercam customers worldwide. If you would like a custom post or a modification to an existing post, please click below to fill out a custom post request form.

How do you get a post processor installed?

Step 1:

Contact your local Reseller to request the post. They will provide you with a Post Processor Request Form, which you can then fill out with your machine information. After you submit the form, your post will arrive, most likely by email.

Step 2:

Download the files. Be sure to confirm your Shared Data Folder in Mastercam.

Step 3:

Copy the files to your Shared Data Folder and into the CNC_MACHINES folder. New posts will be added to the folder, but updated posts will overwrite the old versions. Save the files by machine type.

Step 4:

Update Machines List. In Mastercam, click the Machine Type drop-down in the Machine tab, and then choose Manage List. Choose the new machine name, add it, and confirm the process by choosing OK.

Step 5:

Begin programming!

Don’t forget that Cimquest can also help you with our custom post-processor service. More info on that below.

Leave A Comment