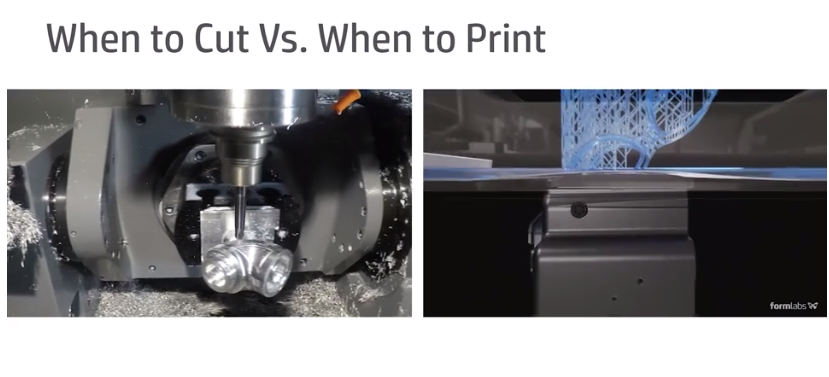

Additive manufacturing builds parts by adding material layer by layer, while subtractive removes material to create parts. Although these approaches have different benefits and can serve different purposes, they are often used in conjunction with one another due to their overlapping range of applications.

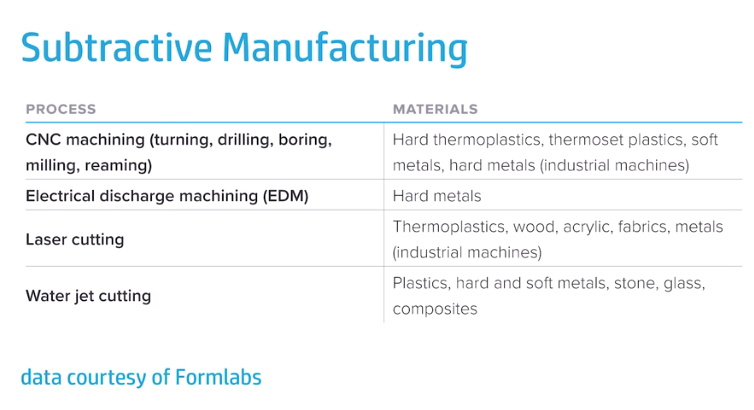

In subtractive manufacturing, the most popular being CNC machining, you’ll typically start with solid blocks of materials that are shaped through cutting, boring, drilling, and grinding. These processes rely on a virtual CAD model to serve as input for the fabrication tool. There are many types of subtractive processes, depending on the materials and parts being shaped.

Subtractive manufacturing processes are typically used to create parts for prototyping, manufacturing tooling, and end-use parts. There’s also a variety of material and processing methods.

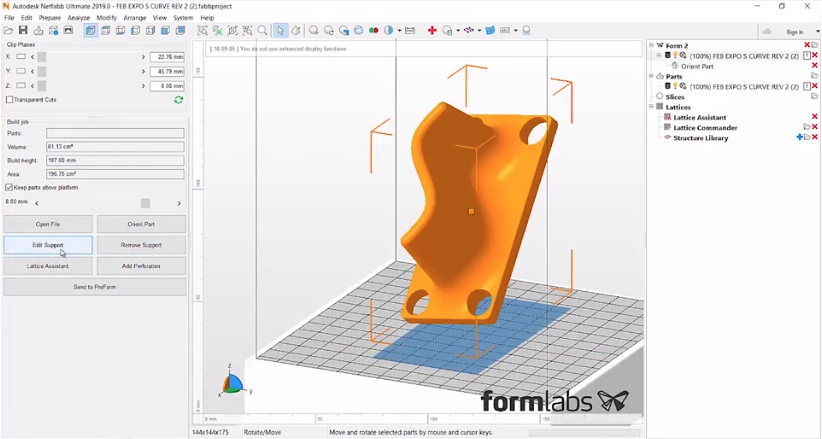

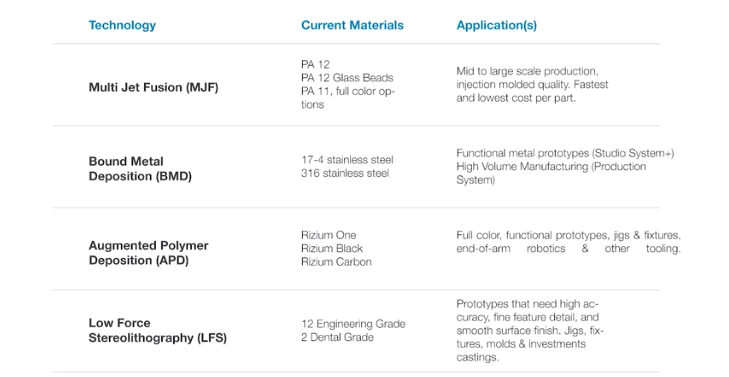

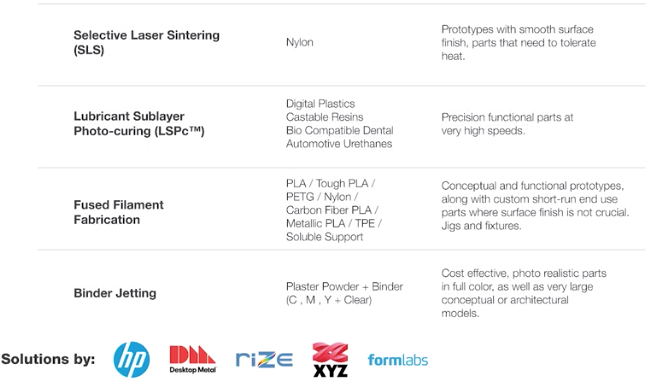

Like subtractive, additive also relies on a CAD model. Depending on the technology, the 3D printer deposits material, selectively melts and fuses powder, or cures liquid photopolymer materials to create parts.

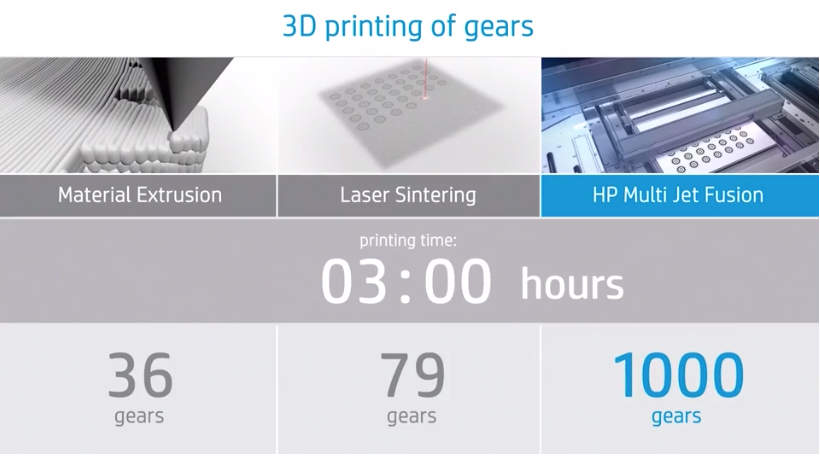

The 3D printed parts often require some form of cleaning and finishing to achieve their final properties and appearance. Additive manufacturing is ideal for a range of applications, including prototyping, manufacturing tooling, short-run production and casting patterns. But technologies released in recent years have made it possible for larger-scale production due to increases in speed and throughput.

With additive, there is not just one technology that fits all but instead an assortment of technologies that use different materials and appeal to specific applications.

While there are key differences, subtractive and additive manufacturing are not mutually exclusive. Prototyping relies on both, but early concept models are more economical and faster to produce with additive. Additive technologies are also typically better suited for small parts and highly complex or intricate designs.

Once we move into the later stages of development with larger volumes, subtractive processes can become more competitive. In this case, larger less complex objects are produced better through subtractive or even casting or forming processes.

We hope you enjoyed this comparison of additive versus subtractive manufacturing. Please be sure to sign up for our 2 Minute Tuesday video series to receive more articles like this one in video form every week. More info at the button below.

Leave A Comment