Metal 3D Printing for Manufacturing

Reprint from www.techcrunch.com Desktop Metal has already earned a number of fans with its 3D printed metal technology — Lowe’s, Caterpillar and BMW were all among its earliest clients. As first noted by CNBC, the Massachusetts-based startup is also getting some healthy monetary support, adding $115 million of venture funds to its coffers this week. The Series D features a number of high profile names, including New Enterprise Associates, GV (formerly Google Ventures), GE Ventures, Future Fund and Techtronic Industries, the holdings company that owns Hoover U.S. and Dirt Devil. Founded in 2013 by four MIT professors, Desktop Metal isn’t the first company to bring metal 3D printing to market, but it’s probably the most efficient. By its own measure, the company’s machines are able to print objects at up to 100-times the speed of their competitors. That’s good news for those clients using Studio, the prototyping machine the company announced last year — but even more useful for those planning to use the upcoming Production, a system designed to bring the technology to manufacturing. Speed has been of the main bottlenecks in mainstreaming 3D printing for manufacturing — metal or otherwise. The Production system isn’t going to replace wide scale manufacturing any [...]

Cimquest Expands its Mastercam Team

Big News from Cimquest . . . We Have Expanded our Mastercam Team (and Customer Base) We are very excited to announce that our Mastercam support team and customer base have significantly grown. Cimquest and Fisher Unitech have engaged in an exchange of service between the two companies and Cimquest will now be supporting the Fisher Unitech Mastercam customers. Additionally, Cimquest Stratasys customers will be supported by Fisher Unitech. Fisher Unitech will no longer be representing Mastercam and Cimquest will no longer be representing Stratasys. We would like to welcome Brian Brown, Tony DiSanto, Chris Jepson, Andy Lowry, Todd Patterson, Jeff Reiser and Mike Steelman to our Cimquest team. We are excited to have such a strong team of Mastercam experts to add to our world-class talent who together will offer unparalleled support, consulting and training services to the manufacturing community. With the addition of the Fisher Mastercam technical team, Cimquest will be the largest Mastercam support organization in the world! Although Cimquest will no longer be selling and supporting Stratasys products, we now have the opportunity to build a much more diversified 3D printer portfolio to better serve our customers’ needs. We are very excited that we are diversifying our 3D Printing focus into [...]

CMM Inspection without a Master Part

Have you ever needed to inspect parts in a CMM, without having a master part? Automated CMMs can be a great time saver when inspecting parts on the shop floor. Traditionally, a master part is measured to generate a master data set. The same routine is then automated and used to measure each production part. Each production data set is then compared to the master data set to determine the actual size of the part and whether it is within user defined tolerances. But what if you don’t have a master part available, or one that was closely produced to drawing nominal? This is where the CMM Master can be a great solution. The CMM Master, based on the Renishaw Equator platform, is a portable, automated CMM, calibrated for high production shop floor inspection. In conjunction with the Verisurf software, it is volumetrically error mapped to increase the traditional Renishaw Equator accuracy down to .0005”. Here you see the CMM Master running an automated measurement routine. When it’s done, it automatically generates a date and time stamped report. One thing that makes the CMM Master unique is that a master part is not required in order to perform on the fly measurements. You [...]

New Metal 3D Printing Process

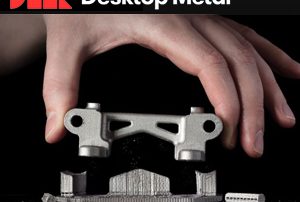

Bound Metal Deposition Uses MIM to Create New Metal 3D Printing Process by Dave Macfie and Shawn Spinneweber, Cimquest The advent of metal 3D printing, also known as additive manufacturing, has promised to dramatically change the way products are made. The benefits are: the reduction or elimination of up-front tooling and increased complexity due to the removal of conventional manufacturing constraints which lead to shorter lead times, part consolidation, and weight reduction. Today, metals represent one of the fastest growing segments in 3D printing globally. Shipments of metal 3D printers increased by 51% in 2015, compared to 2014, and they continued to climb in 2016. Various research firms project additive manufacturing will be a $20B industry by 2020. (Source: Wohler’s Report 2016). While global metal manufacturing is estimated to be a $1 trillion industry. In spite of this growth, metal 3D printing options have not been accessible for the majority of manufacturers due to their cost and operational complexity. In addition, most technologies have relied on slow, laser-based processes that demand high levels of manual labor such as removal of metal supports with CNC. Handling the metal powder also poses health and safety issues which require a larger investment in equipment and facilities. [...]

3D Printing for Low Volume Production

Companies in certain industries sometimes require customized end-use parts, used to either replace older parts or improve upon infrastructure. While necessary, the cost and time barriers associated with one-off parts can cause for engineering teams to postpone or even eliminate projects altogether. Siemans Mobility based in Germany develops technology for vehicles and infrastructure for transport machines. The unique needs of their customer base demands innovation in low run manufacturing. One of their customers, The SWU Verkehr, provides transport services across 10 trains in the city of Ulm. The SWU decided to rework an existing armrest for the driver seat of a city train. This modification included the addition of three extra buttons for the control system, a design requested by many of their train operators. While something like this seems fairly straightforward, the part is traditionally made from glass fibre plastics with injection molding, welding, and milling. Through these methods, Siemens would be limited to only taking orders above 10 parts, because anything lower would be cost prohibitive. Excess parts would be stored until they were used or became too outdated to use. With this growing demand for one-off parts, Siemens saw the opportunity to innovate with 3D printing. This justified the nearly [...]

FDM Thermoform Tooling: What It Is and Why It Works

A kitting tray 3D printed using thermoformed plastics. There’s a good chance you interact with multiple thermoformed products on a daily basis, whether that be in your grocery store, your car, or probably even your fridge. But what does it mean if something is thermoformed? Thermoforming is a conventional plastics forming process where heat is used to bring a sheet of plastic to its sagging point, or when it becomes pliable. The heat source is removed and the plastic sheet is positioned onto a mold. A vacuum is then drawn through the mold and the sheet conforms to the surface of that mold. Thermoformed products are prevalent throughout manufacturing industries; including medical, outdoor/recreational equipment, automotive and aerospace. Typical products most commonly seen are trays, various housing components, wind deflectors, tubs, and most frequently — packaging. Using conventional methods, creating the tools for thermoforming can be a long, grueling process. Often these tools, especially if outsourced can take anywhere from 6-14 weeks depending on tool complexity and CNC capacity. This timeline is unattractive when you only need tooling for a short production run or a prototype tool. Typically, short-run, prototype and bridge tooling are made of a lower-cost tooling board. These materials [...]