Students Build Lighter, Faster Formula SAE Competition Cars

What’s in your toolbox? For Cyclone Racing, an automotive racing team from Iowa State University (ISU), it’s 3D printing. These students are discovering the benefits of additive manufacturing while having fun competing in the famous Society of Automotive Engineers (SAE) International Formula car competition. In the Formula SAE competition, students are instructed to design, build and then test their open-wheel racecar, which will then be raced against other collegiate teams. Students 3D printed the intake assembly with the throttle cable directly on top of it. ISU student competitors are pushing the limits of collegiate racing by making the manufacturing process a whole lot simpler. This year it means that the Iowa team created their best Cyclone yet – the CR-21 – using design for 3D printing. A Stratasys Fortus 450mc 3D Printer with ULTEM1010 3D printing material was chosen; ULTEM1010 especially for its thermal and chemical properties and superior strength. So, what did students consider before 3D printing? What will the complexity of the car be? What will the optimal weight be? What types of force will act upon it? With these criteria taken into consideration, the students decided to 3D print three components for the Cyclone racer: the intake, the [...]

Stratasys 3D Printing Helps Eyewear Icon Re-Invent Design

Stratasys full color, multi-material 3D printing (J750 3D Printer) allows Safilo to quickly iterate designs and reduce turnaround time for product-matching prototypes by 60%. Founded in 1878, Safilo was propelled to success and is now the second-largest producer of eyewear in the world. The company is renowned for its stellar craftsmanship and manufactures sunglasses, sports eyewear and frames for prescription lenses for more than 90,000 stores in 130 countries. The company’s impressive portfolio boasts 25 luxury brands, such as Dior, Fendi, Jimmy Choo and Hugo Boss, as well as five of its own brands, including Carrera, Polaroid and Safilo. Safilo’s exacting standards for style, creativity, functionality and quality demand accurate and true-to-life prototypes throughout the design process. The large number of frames produced by the company also demands efficient and timely throughput during the design process. Previously, the company produced its concept prototypes with a CNC machine, which the team would use as a template when manually developing the actual prototypes. This resulted in lengthy lead times and, if iterations were required, would also prove costly further down the production line. Perfect for Design and Concept Verification: 3D Printed Prototypes Enable Immediate Decision-making To overcome the bottlenecks associated with traditional manufacturing, [...]

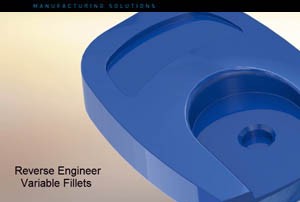

Reverse Engineering Variable Fillets

Let’s explore how to reverse engineer a variable fillet from a polygonal mesh . . . When reverse engineering a physical model, radius values can be measured with various types of radius gauges. It can be somewhat of a challenge if the fillet face is worn, chipped, or distorted. In addition, the task becomes more complex if the fillet is not constant, that is, if it varies along the edge like the mouse shown below. How would you reverse engineer such geometry? A good software product that can be utilized for this type of work is Geomagic Design X. Above, you can see a polygonal mesh superimposed by the CAD model. If you add a fillet to the CAD model and click on Estimate Radius from Mesh you will get an averaged value that you can work off of. You can then set this to the desired value, in this case, a 1-1/2 mm fillet. The real power is shown when you have a variable radius. After you pick the edges involved, simply match the CAD values to the averaged radius values along the mesh. If you want to be more precise, type the values in directly. When satisfied, accept the command and [...]

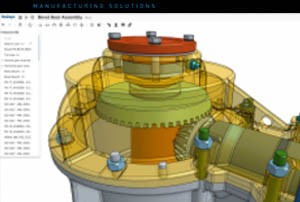

Onshape Training Class

Cimquest is proud to host the first formal Onshape training course on November 15-17, 2016, at Cimquest Headquarters in Branchburg, NJ. The course will be taught by Onshape Instructors and the material along with the in-class exercises will cover everything from Parts, Assemblies, to Drawings…soup to nuts. This three-day class will be offered for $1250 and limited to a maximum of 15 students. We are offering a special 25% discount for those that sign up by November 2nd. With this discount, the price of training drops to $937.50. Don’t miss out on this special offer! Cloud Based 3D Modeling Onshape is professional 3D CAD. Create complex parts, assemblies, and detailed drawings all within your web browser. Easily define parameters and relationships to allow designs to be easily modified. Use mates to build realistic assembly motion. Built for Design Teams Like Yours Onshape is the first CAD system built for teams. Collaborate with your colleagues, vendors, and partners in real time. Version control is built in. Never lose track of the latest version of your work again. Control access, work together simultaneously and branch designs – all from within Onshape. That’s full-cloud CAD. Register for the course by clicking the button. Register Here [...]

Actualización de la Definición del Material en Bruto

http://cimquesttv.wistia.com/medias/na5w2cwhnp?embedType=async&videoFoam=true&videoWidth=640 Reconocimiento del Material en Bruto ha sido integrado al permitir que la operación Modelo De Material En Bruto actualice la definición del Material En Bruto de Torno

Style X 2016 – Blending Fashion with Technology

By Brendan Conley, Marketing Specialist - Cimquest Inc. Last month, Fashion Week emerged on the streets of New York City, presenting the top new trends, fads, and style movements of the industry. Cimquest and Stratasys partook in this year’s excitement by exhibiting at Style X, an experiential platform which showcases contemporary companies who blend fashion with new technology. The venue included a Design Leadership Panel, featuring avant-garde designers and innovators driving change in the industry. The Panel focused on 3D printing and other emerging processes that can potentially complement traditional production methods. In fashion, 3D printing can be used as a tool to fabricate conceptual designs and even assist in final production. At Style X we had a variety of parts on display, most notably prototypes printed through PolyJet technology. PolyJet is great for clothing items due to its multi-color/multi material capability. You can create things like realistic sneaker prototypes in a blend of rubber-like and rigid materials, or alluring jewelry with detailed textures. Full color 3D models transform 2D concepts into realistic tangible prototypes. They offer designers a detailed perspective early on in the design process, making it easier to revise and progress. 3D scanning can bring product [...]