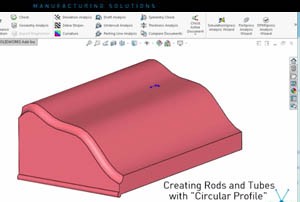

Creating Rods and Tubes in SolidWorks 2016

SolidWorks 2016 includes an enhancement to sweeping solids, cuts, and surfaces that will allow you to create a solid rod or hollow tub along a sketch line, edge or curve directly on a model without having to create a new sketch. This is possible with the new “circular profile” option in sweeping operations. The example part above has several edges that can be used as sweep paths. In order to cut a tube through the part, go to Insert > Cut > and select Sweep. In the property manager, under Profile and Path, click Circular Profile. In the graphics area, select a curved edge for the path and set the diameter to 50 mm. In the Property Manager under Options, notice that Show Preview and Align with End Faces are selected by default. Accept the changes to the command and observe the tubular cut through the part’s edge. Now, to create a solid sweep with a circular profile, go to Insert > Boss/Base > and select Sweep. In the Property Manager under Profile and Path click Circular Profile and select the bottom edge of the part in the graphics area for the “path.” In the Property Manager, set the diameter to 20 mm. [...]

Tips and Tricks Using FDM Materials in 3D Printing

Currently, about 75% of all new 3D printers sold are FDM printers, and quite a few of them are used in business environments. The Stratasys Fortus family of commercial FDM 3D printers are used in high-production facilities through industries as diverse as consumer products, automotive, aerospace and even medical applications. Stratasys also offers some of the more advanced FDM 3D printing materials on the market, many of them with incredible end-use applications. Stratasys ASA 3D printing material is available in ten different colors. Unfortunately there is more to 3D printing than just pressing a button and waiting for your finished part to be ready. Not only does printability need to be considered during the design phase, but once a 3D model is ready to be printed a technician needs to carefully orient the model on the build plate in order to maximize the quality of the materials, ensure a quality surface finish and reduce or eliminate the amount of supports that will need to be removed. Unfortunately many 3D printing materials are very different from each other and will react in different ways depending on how they are used. The very best way to learn how to use a 3D printer [...]

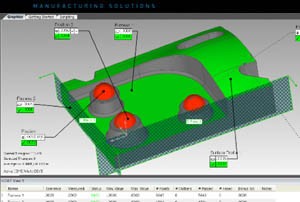

Non-contact Inspection for CAM Users

Do you have a manufacturing facility or job shop looking for a more automated way to do part inspections and deliver a professional date-and time stamped inspection report to your customers? Combining the Creaform HandySCAN 700 and Geomagic Control software, inspect parts thoroughly and accurately to very close tolerances in just minutes using state-of-the-art laser scanning and best-in-class inspection software. Utilizing the same 3D models used for machining, Control places customer datums onto the model, transfers those datums to the scan, aligns the scan with the model and performs a complete inspection including; Color mapping, 2D Whisker plots, 3D Annotations, Feature-based comparisons, GD&T, 2D and 3D Dimensions as well as a fully configurable date and time stamped inspection report. Once the process is finalized and the first part inspection is completed, inspect the balance of the machined parts in a batch mode, allowing Control to do 100% of the work! Please email Joel Pollet, Senior Services Specialist for Cimquest, for more information.

Ultem 9085

There are many different materials available for 3D printing and today we are going to talk about ULTEM 9085, which is a production grade thermoplastic used for high-performance parts. Known for its reliability, ULTEM 9085 has superior thermal, mechanical, and chemical properties. This thermoplastic is flame-retardant with a high FST rating. This certification paired with Ultem’s high strength-to weight ratio makes it ideal for aerospace and automotive applications, particularly in commercial airplanes and marine and ground vehicles. And while ULTEM 9085 doesn’t have as high of a compression strength or stiffness as ULTEM 1010, it does have the highest impact and fatigue resistance, along with more ductility. ULTEM 9085 is available on the Fortus 400, 450, and 900mc. It uses a breakaway support structure, with two different layer thickness capabilities. When this material was first released, it was only available in a standard tan color, for example this air control duct and grill. However black was eventually added to the lineup because of the color’s aesthetical appeal and uniform look. Black also masks dirt and stains that tend to arise from functional use. Because of ULTEM 9085’s high tensile strength and impressive heat deflection, manufacturers are using it for advanced functional prototypes and [...]

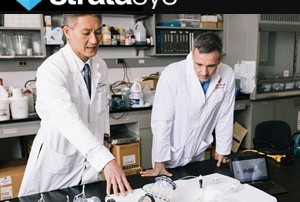

3D Printed Vascular Simulations Improve Cardiovascular Disease Treatment

Vascular disease is a common malady affecting the blood vessels, and ultimately posing a risk to every organ in the human body. According to the American Heart Association, cardiovascular disease is the leading global cause of death, accounting for more than 17.3 million deaths per year, a number that is expected to grow to more than 23.6 million by 2030. Treatment options available have been steadily evolving from traditional open surgery to more minimally invasive, endovascular techniques in which specialized catheters are threaded through the arteries to treat specific conditions. These new techniques and devices have dramatically altered the way we now treat coronary artery disease, cerebral aneurysms, carotid stenosis, abdominal aortic aneurysms and other vascular problems. With this revolution in clinical treatment, physicians are constantly challenged to learn new skills. 3D printing is a critical tool in the struggle to keep up with an ever-changing clinical environment. Vascular Simulations Replicator can be used in an angiography suite, visualizing the custom silicone vasculature using contrast injections and fluoroscopy, similar to patient treatment. Without accurate simulation models, clinical judgment is acquired from many years of experience treating many patients, frequently resulting from complications during procedures. But what if this knowledge can be [...]

Cimquest at the Atlantic Design Show

Cimquest recently exhibited at the Atlantic Design & Manufacturing Expo (ADS), which took place at the Jacob Javits Convention Center in New York City. This show delivered the latest innovations in engineering software and 3D printing and Cimquest took the opportunity to display some great new technology. From our 3D printers and scanners to inspection devices and even CAD/CAM, we were able to exhibit the full manufacturing solution. One of the biggest highlights in our booth was the new Stratasys J750 full color printer that can produce fully textured parts. We also displayed some scanning options including the Handy Scan scanner. This mobile device is portable and lets you easily move it around the part. This device can capture about a half a million points every second! With lots of display parts in the booth and a team of manufacturing experts on hand to show off all of our manufacturing solutions the show was a great success. Many thanks to those who came out and stopped by. We are already looking forward to the next show.