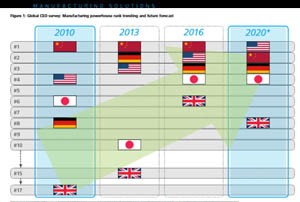

Manufacturing Making a Comeback in the USA

Total output from American manufacturing relative to gross domestic product is back to pre-recession levels, with more than half a million new jobs. Global manufacturing executives predict that by 2020, the U.S. will be the most competitive manufacturing economy in the world. Cheap labor is no longer the most important input for manufacturers. Success in the manufacturing sector can be attributed to the availability of advanced technologies/materials and strong protection of intellectual properties. The U.S. beats out China on both of these. In the manufacturing sector, the U.S. is among the most productive economies in the world in terms of dollar output per worker. A worker in the U.S. is associated with 10 to 12 times the output of a Chinese worker. The wage gap between Chinese and U.S. workers is shrinking at a much faster rate. In addition, customers have come to expect shorter delivery windows. Consumers are accustomed to delivery within one or two days, if not the same day. It’s easier for companies to meet these demands when they are manufacturing their products right here. An example of a company shifting their manufacturing to the United States is Kent International Inc., a bicycle company. They invested $4.3 million in a [...]

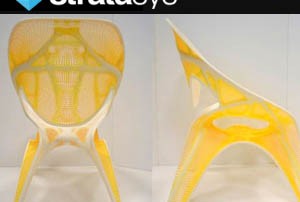

Stratasys Showcases Unique 3D Printed Chair

Stratasys is showcasing a unique 3D printed chair designed by the late Zaha Hadid, with Patrick Schumacher, at a retrospective of Hadid’s work in Venice. The 10-room exhibition, set to run until November 27 as part of the Venice Architecture Biennale, celebrates the life and works of the world-renowned architect, who passed away earlier this year. Since the development of the original 3D printed prototype in 2014, the chair has been featured in various exhibitions and museums around Europe and has continued to be a representation of Zaha Hadid Architects’ (ZHA) commitment to 3D printing. “We are always looking to research new design and manufacturing methods with the explicit intention of ‘scaling up’ for applications in the construction industry,” commented Shajay Bhooshan, Associate, ZHA. “3D printed design projects such as this collaboration with Stratasys are of significant importance for the wider industry. The 3D printed chair epitomizes the bi-directional influence between technology and the way we design that we are always striving to create.” As Naomi Kaempfer, Creative Director for Art Fashion Design, Stratasys, explained: “The Zaha Hadid retrospective in Venice provides an opportunity for us all to pay tribute to the iconic, award-winning architect. Zaha Hadid is undoubtedly the greatest female architect [...]

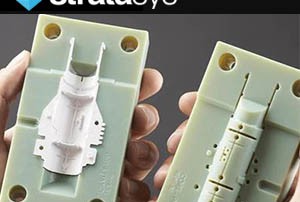

Make Functional Prototypes More Economically

You can make functional prototypes much more economically by using 3D printed injection molds. One of the most dramatic impacts of 3D printing on design and manufacturing is with injection molding. Companies such as Seuffer, Unilever, Arad Group and Whale report significant savings in molding costs and production time by 3D printing injection molds to test designs before mass production and produce small quantities of custom parts. Learn more by viewing this 60-minute webinar as Gil Robinson, Stratasys senior application engineer, explains the what, why and how of 3D printed injection molding. In this webinar, you will learn: When it makes sense to use them. Why companies include them with traditional methods. How much time and cost are saved. What types of materials can be injected. How they enable parts with complex features. Who uses them. Register for this free webinar by clicking on the button below. Register Here

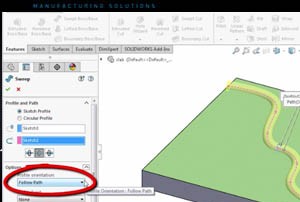

SolidWorks 2016 Bidirectional Sweep

There’s a new enhancement to the sweep function in SolidWorks 2016 that will allow you to create sweeps for a mid-path profile in either direction or bidirectional. In previous versions of SolidWorks, a profile had to sweep the entire length of the path, no matter the location of the profile sketch. This is no longer the case. Now mid-path profiles can be swept using direction 1, direction 2, or both directions. This simple part (below) contains both a profile and a path sketch. Go to Insert > Boss/Base > and select Sweep. In the Property Manager under Profile and Path, click Sketch Profile. And then, in the fly-out Feature Manager design tree, select a sketch for the profile and a sketch for the path. Select Bi-directional and click direction 1 and direction 2 to toggle the sweep display. For profile orientation, click Follow Path and accept the changes. This enhancement to creating sweeps will give you more control over the sweep behavior and more flexibility in your design method. Be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below. More Info [...]

Artistic Visions and 3D Printing

Art and design have certainly benefited from the 3D printing world and its liberating capabilities. Artists with 3D printers have been producing some unique geometries, seemingly “impossible” shapes, and unprecedented combinations of color and materials for many years. The release of the new Stratasys J750 multicolor3D printer has opened up even more new doors in the artistic worlds. In this blog article we will showcase the work of one ground-breaking 3D artist named Jose Sanchez. “Polyomino” is the final stage of a two-year professional collaboration between Stratasys and Jose Sanchez, an architect, programmer and video game designer. This shape-shifting 3D printed structure can be reconfigured using magnets and recalls the building ethos of classic video games like Tetris. With more than 360,000 colors available for use on the Stratasys J750 3D Printer, Sanchez was able to allow the color to be the lead element of the piece. WOLFKIAM by Nick Ervnick is inspired by Mayan and Incan design. The intricacies in color and geometry in the sculpture were made possible by the new Stratasys J750 3D Printer. Photo credit: Yoram Reshef “The artwork uses color as a guideline to construction,” Sanchez said. “Consisting of only two different geometries, we explored the use of [...]

New 3D Technology

Magic Leap is an augmented reality headset developer that is working on technology that is a totally different concept from all the other AR and VR platforms that are out there. Magic Leap’s advisors, Boston-area serial entrepreneur Jon Hirschtick (most recently the founder of Cambridge 3D CAD software firm Onshape) stated, “When people say ‘Magic Leap’s 3D looks really better than others,’ they assume it’s better because it’s higher-resolution. Like how a new iPhone looks better than an old iPhone,” Hirschtick told me. “That’s not it. It’s not a higher-resolution thing. It’s a different concept for how it produces 3D.” The way Magic Leap produces images is by replicating “the way your eyes really work” by bending light fields – rather than by tricking the eye (using “stereoscopic” imaging) as other platforms do. With other projected 3D images, the 3D stops working when close one eye—though of course, you can still see 3D images in real life with one eye closed. That’s what Magic Leap has figured out how to do—which has been “an unbelievably ambitious project.” This technology works the way you normally see things. If you use the Magic Leap device and close one eye, and there’s a synthetic monster walking [...]