Stratasys Demonstrates Advantages of 3D Printing at 32nd Annual Space Symposium

The 32nd annual Space Symposium was recently held at the historic Broadmoor in Colorado Springs. New capabilities and markets are opening in the commercial space and there is renewed focus in the civil market – driving science and exploration to new heights. To achieve these lofty aims, there are new technologies being brought to bear – decreasing cost and increasing utility in the industry. 3D printing is one of the technologies supporting this period of aggressive innovation in aerospace. This is the second consecutive year that Stratasys has been invited by United Launch Alliance (ULA) to participate in their exhibit, and is also the first appearance for a Stratasys booth. In the year since the last Space Symposium, Stratasys has had the opportunity to highlight how ULA has adopted Stratasys FDM 3D printing solutions and ULTEM 9085 material in some very innovative ways. Dual presence with a Fortus 250 printing rocket models in the ULA booth, and a Fortus 450mc 3D Printer printing a light-weight camera mount in the Stratasys booth. Last year, ULA discussed how they undertook flight-qualifying 3D printed thermoplastic parts, and the millions of dollars they would save from consolidating parts and replacing aluminum with plastic. Flight qualification [...]

3D Printing and Fashion

Rapid prototyping offers solutions to engineering obstacles over a wide spectrum of industries. A business focusing on manufacturing new pharmaceutical devices, for example, is just one of the many sectors that we would typically expect to have been positively influenced by this cutting edge technology. Naturally, the public has been awestruck by these innovative printer and people are eager to get their hands on one – well, that is, if they can afford it. One group in particular showing an interest with this applied science is the fashion industry. Designers are utilizing 3D Printing technology to offer a unique and artistic twist to the already fashion-forward garments they create for their models. Is it possible that society is trending toward wearing 3D Printed items as part of their everyday attire? There are some designers out there looking to make a statement, both on and off the runway. Last Spring, Dutch fashion designer Iris van Herpen, had a 3D Printed dress featured during a fashion show in Paris. Van Herpen worked to create this icicle-like dress with the “Father of 3D Printing,” Chuck Hull. Hull invented the Stereolithography or “SLA” printing method, where thin layers of plastic are printed from bottom to top, and [...]

Stratasys Announces GrabCAD Print

Stratasys today unveiled a bold, new software strategy designed to make 3D printing significantly easier, more intuitive and highly accessible. The approach is powered by a new, open architecture “design-to-3D print” workflow application, GrabCAD Print* – residing on the popular GrabCAD SaaS platform and supported by a community of more than 3 million designers, engineers and students. GrabCAD Print is designed to make 3D printing fast and easy-to-use, while reducing errors by eliminating requirements to translate and repair CAD files. Product designers, engineers, and 3D printer operators can now send native CAD files to a Stratasys 3D Printer or service bureau directly from their familiar CAD environments. GrabCAD Print works with a variety of Stratasys FDM and PolyJet 3D Printers and can natively read several popular CAD formats from PTC Creo, Dassault Systèmes’ SOLIDWORKS, Siemens PLM Software’s NX software, CATIA and Autodesk Inventor. The application also facilitates data sharing related to job scheduling, print queue status, material usage and historical usage. All information is readily available via standard Web browsers, mobile applications or locally installed clients while securely managed through the GrabCAD Platform. “When we acquired GrabCAD two years ago, our vision was to provide a digital manufacturing backbone to support adoption of [...]

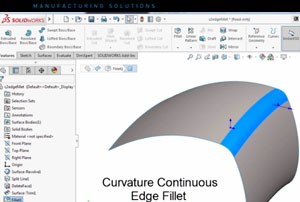

Curvature Continuous Edge Fillet – SolidWorks 2016

There is a new enhancement in SolidWorks 2016 that will allow you to define the edges of constant and variable fillets as curvature continuous. This option creates a smoother curvature between adjacent surfaces. Here’s an example of how it works . . . The part shown above contains two surfaces that meet at a sharp edge. Select the edge, and go to Insert > Features > and select Fillet/Round. In the property manager under Fillet Type, click Constant Size Fillet. Next, under Items to Fillet, select both Tangent Propagation and Full Preview. Under Fillet Parameters, select Symmetric in the drop down list and then set the radius to 40 mm. Finally, under Profile select Curvature Continuous. Save the changes and observe the smooth fillet that is tangent to both surfaces. When creating edge fillets, this new option will allow you to easily make smooth fillets that are continuous to the adjacent body curvature. Be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below. More Info

Objet Connex 3 Overview

The Objet Connex 3 by Stratasys is a renowned series of machines in the 3D printing industry. The Connex 3 first entered the market in 2014, functioning through PolyJet technology. Its release was monumental as it was the first 3D platform to offer multi-material, multi-color 3D printing. Since then, it has evolved into an industry standard, operating at an elite level of performance that designers and engineers around the world depend on. The Connex 3 combines three base materials to produce a variety of part types, ranging from rigid to rubber-like, opaque to transparent, standard to bio-compatible and more. It can build up to 82 material characteristics into an individual part or assembly, while achieving a wide range of color options and shore A values. This makes it perfect for creating realistic prototypes with smooth surface finish, rich vibrant colors, and realistic feel. With the Connex3, users can also print in Digital ABS, a strong composite that has high temperature resistance. Digital ABS can be used for a variety of applications including functional prototypes, manufacturing tools and fixtures, injection molds, electrical parts and casings, and end use parts. It is great for parts that require high impact resistance and shock absorption. The Connex [...]

Professors Teach Students About Water by 3D Printing It

Repost from http://3dprint.com/ Ryerson University professors Claire Oswald and Claus Rinner have come up with a novel way to teach their students about local watersheds and the problems that they face. Working with Ryerson-affiliated 3D printing company Think2Thing, they’ve begun 3D printing scale models of Toronto watersheds, so that their students can actually hold the bodies of water in their hands. So far, they’ve printed every watershed in the Toronto and Region Conservation Authority. “The reason that we’ve been doing these 3D printings is that we think that they might be really useful for helping people understand…some issues that our watersheds are having and also to point out some environmental stewardship opportunities,” Oswald said. The two professors used the printers at Toronto Reference Library’s Digital Innovation Hub to print out their first model, a 3D elevation model of the Don River. The river, which empties into Lake Ontario, is a vital watershed in the Toronto region, and the biodegradable PLA model that Oswald and Rinner created shows not only its shape but its currents and surface variations. Students can run their hands over its surface, seeing and feeling its textures and waves. Oswald and Rinner have also enlisted undergraduate students from Ryerson’s Geographic [...]