Stratasys New J750 3D Printer Brings One-stop Realism to 3D Printing

Stratasys has once again transformed the impact of 3D printing on product development and delivery with the new Stratasys J750 3D printer. This new solution enables customers — for the first time — to mix-and-match full-color gradients alongside a wide range of materials to achieve one-stop realism without post-processing. This, together with the system’s superior versatility, makes the J750 the ultimate 3D printing solution for product designers, engineers and manufacturers, as well as service bureaus. As the latest addition to the Objet Connex multi-color, multi-material 3D printer series, the J750 3D Printer enables efficient informed decision-making to help accelerate the way products are designed, evaluated and brought to market. A true industry milestone, the J750 is expected to improve Total Cost of Ownership (TCO) by eliminating many of the traditional complex processes, time and resources required to create product-matching prototypes. Designers and engineers can physically experience true product prototypes within hours of developing an initial concept for immediate design and function validation with internal stakeholders and end users. The new Stratasys J750 3D Printer transforms product design with full color 3D printing and texture mapping to create realistic prototypes in a single print operation, such as these cosmetic tubes. “We’ve used [...]

Top 5 Reasons to Train Your Employees

The biggest, and likely most obvious, reason to train your employees is that it increases their productivity and quality through increased abilities. Training ROI on an employee can be equal to, or better than, a monetary pay raise while building confidence and commitment. Training increases employee morale, motivation, and creativity. Believing in your employees enough to send them to training gives them a sense of belonging and worth, which increases morale, motivation and creativity. Be sure to be open and make time to listen to all their new ideas when they get back. Training can increases communication and trust between employees and managers. Managers can be both the weak link or the magnetic force that keeps employees with a company. Managers and employees should discuss goals and expectations before training. After training, discuss the best thing(s) employees learned and how they can be implemented. Remember, employees don’t leave companies–they leave managers. Training intangibles - When employees are better prepared technically they have a higher positive attitude, which correlates to better customer relations and reduced scrap rates. Stay tuned for another training-related blog post next week when we will discuss how to get the most out of employee training. For more information on the [...]

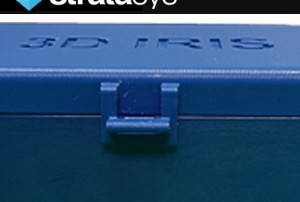

FDM Part Smoothing

When you are looking for a way to make very functional FDM parts look closer to being traditionally manufactured parts there are few methods out there. Some of these require manual working of the part, some mechanical, while others require almost no work at all. One of the major concerns that comes up regularly is the dimensional stability of the parts after the finishing process. When tumbling parts or sanding them you are typically removing small amounts of material from the surfaces, especially the edges, and this can be an issue if not monitored carefully. Another process that can smooth out parts is to coat the part with either an automotive body filler type substance (ideal for painting parts when dimensions are not critical) or using a two part epoxy type product to smooth and gloss a part over. Both of these methods work, but they are time consuming and will affect the dimensional accuracy of the part(s). The top lid of this box has not been smoothed or post-processed, while the rest of the body has been. The FDM stair stepping lines are clearly visible on the lid, but not on the body. One of the fastest and most dimensionally accurate [...]

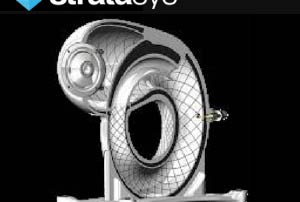

How Stratasys 3D Printing Completely Turned Around Stereo Speaker Acoustics

You can’t solve an 80-year-old problem with 80-year-old technology. Take stereo speakers, for example. Conventionally designed and manufactured speakers almost universally suffer from some level of “back wave” distortion; this occurs when the audio signals fired to the back of the speaker bounce off the cabinet walls and interfere with the signals sent to the front of the speaker. In the 3D printed Aleph1 speaker design, sound travels in a perpetual self-feeding loop, preventing it from interfering with the signal outputting to the front, for extraordinary acoustics. To solve the problem without using acoustic absorption, industrial designer Boaz Dekel, a graduate of the Bezalel Academy of Arts and Design came up with a truly unique solution: Eliminate the speaker’s back wall. Dekel conceived of a circular speaker in which sound travels “in a perpetual self-feeding loop that prevents it from interfering with the signal outputting to the front,” as he explained to the Stratasys Blog. Sounds like a great idea? Yes. But it also sounds impossible to manufacture using conventional tooling methods. So Dekel turned to Stratasys 3D printing to prototype his design. The Aleph1 speaker being 3D printed in one piece on the Objet500 Connex3 color, multi-material 3D printer. [...]

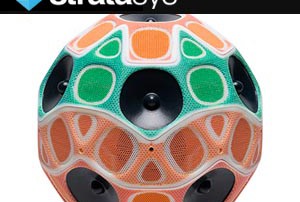

Objet Connex3 with Stratasys Creative Colors

reposted from www.deskeng.com Color 3D printing showed its promise years ago. But there was a gap between promise and bloom. Early color 3D prints had color, sure, yet they lacked the vibrancy of a Cassius Marcellus Coolidge oil. Often parts were paint-by-numbers garish or dreary like the piping on a frozen cake. Objet multi-material, multi-color 3D printers from Stratasys changed that for the better with bright, deep colors. Today’s Pick of the Week, however, is about the blossoming of color 3D printing with the subtleties of color and texture that can turn heads. The elevator speech is that Stratasys has partnered with Adobe to bring Adobe’s color management expertise to Objet Connex3 3D printers and clients of the Stratasys Direct Manufacturing parts on-demand service. The form of this technology partnership is Stratasys Creative Colors software, and the Objet Connex3 is currently the only 3D printer series with Adobe Color management benefits, according to Stratasys. This working prototype of a stereo speaker was produced on an Objet Connex3 series 3D printer using Stratasys Creative Colors software, which leverages the Adobe 3D color print engine. Image courtesy of Stratasys Ltd. and Business Wire. Stratasys Creative Colors creates a direct connection between Adobe Photoshop [...]

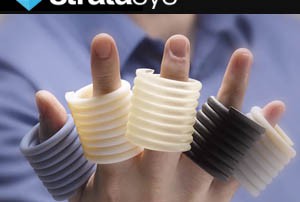

Stratasys Rigur 3D Printing Material For Superior Prototyping Versatility

There are many unique advantages of the Stratasys PolyJet Rigur 3D Printing Material and when it is combined with Tango rubber-like materials they make a powerful combo. Watch the video below to see Sam Green from Stratasys Materials explain the unique advantages. Together, these materials can produce a range of versatile prototyping options that can satisfy all prototyping requirements from concept modeling to advanced functional prototyping. Special Promotion From now until the end of March customers can get a 7% discount on their next Rigur/Tango 3.6kg order over 3 cartridges and PolyJet desktop customers can get a 7% discount on their next 2x2 cartridge order of Rigur, VeroClear and High Temp material. Please contact for more info by clicking the button below. More Info