Swing into the Future: 3D Printing’s Role in Modern Golf

In the world of golf, precision and innovation go hand in hand. The quest for the perfect putter has led enthusiasts and professionals alike to explore various materials, designs, and technologies. Enter the realm of 3D printing—a groundbreaking technology that is redefining the boundaries of golf equipment. Please join us at one of our upcoming events: “Cimquest Manufacturing Expo: Teeing Up Innovation” on June 11th at our headquarters, located in Branchburg, NJ, and “Metal Optimization: An In-Depth Look into Xact Metal at Voxel” on July 9th at Voxel’s headquarters in Cincinnati, OH where we will explore 3D printings role in golf’s star; the putter. We have two exciting giveaways in addition to all the fun goodies you'll receive at the event: a Yeti Cooler filled with our partners' swag and a "one of a kind" 3D Printed golf putter! While we are doing golf giveaways and it is golf-themed, you don't have to love golf to attend! We will have multiple partners there to showcase their technology. In addition to our staff, experts from the following companies will be attending: Desktop Metal Formlabs presenting the new Form 4 UltiMaker HP Xact Metal These pros will be at the various stations throughout the expo and [...]

Overview of Silicone Molding 3D Printed Tooling

Traditional molds for silicone part production are CNC machined from blocks of aluminum or steel. These include two-part or multi-part injection molds for liquid silicone rubbers (LSR), or single cavity compression molds used with a heat-cured rubber (HCR) silicone sheet that is cured under pressure and high temperature. Normally these types of metal molds are used in mass production. However, when employed for prototyping, lead times of several weeks and upfront tooling costs of hundreds to thousands of dollars limit a designer’s ability to implement and test small changes in a mold design. Desktop 3D printing is a powerful solution to fabricate tools rapidly and at a low cost. It requires very limited equipment and enables skilled operators to focus attention on other high-value tasks. With in-house 3D printing, manufacturers and product designers can introduce rapid tooling into the product development process to validate design and material choices prior to transitioning to mass production. They can iterate quickly, accelerate product development, and bring better products to market. 3D printed tooling using Formlabs SLA resins offers many advantages to product designers across prototyping, small-scale production runs, and custom part production. Using 3D printed tooling, RTV two-part silicones are injected into a two-part or multi-part [...]

Accelerating Prototyping and Testing with 3D Printing

Established in 1906 and headquartered in Italy, Panelli Srl is a leading manufacturer of submersible pumps and motors. Thanks to recent investments in industrial automation and the extensive use of robotized assembly, Panelli can offer various products with high hydraulic characteristics. Historically, the company only used a traditional industrial 3D printer for prototyping, but materials costs were high. As a result, Panelli added the UltiMaker Method XL 3D printer, a cost-effective and comparable alternative, allowing the company to successfully achieve the dual goals of cost efficiency and superior quality in their prototypes. Prototyping and testing large parts that can withstand high impacts Panelli’s technical department employs 3D printing to prototype its pump components and ensure that all parts are up to specifications. The team currently uses a simple industrial 3D printer and needed to add another one to support its growing design and production needs. “We print very often, almost daily,” said Francesco Zamirri, mechanical designer at Panelli. “Especially when we need to improve the hydraulic performance of an existing range or create a new one.” However, traditional industrial printers can be rather large and expensive, both to operate and maintain. The team needed something more affordable and that would not require much [...]

Xact Metal Launches New 3D Printing Moldmaking Initiative

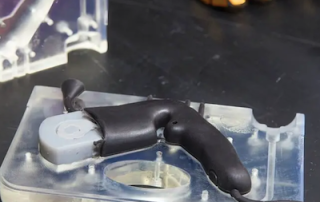

A reprint from Moldmaking Technology. Xact Metal is reframing its metal additive technology as a valuable option in a mold builder’s toolbox through expansion of its moldmaking and material partnerships. Shown here is an Xact Metal printed automotive connector insert on a tool with the corresponding plastic injection molded final part. Source | JST Sales America, Inc., an Xact Metal customer. Xact Metal has announced the launch of its new initiative, “Breaking the Mold: The Xact Solution to Better Tooling.” This initiative aims to change the approach to metal 3D printing in the tooling industry by reframing the technology as a valuable option in a moldmaker’s toolbox. Available with less investment than traditional metal 3D options, Xact Metal says that its printers can generate profit for molding and tooling businesses alike, demonstrated by a growing portfolio of customer successes. More than 140 machines have been installed globally, and Xact Metal is confidently expanding into the tooling space through strategic material partnerships, fine-tuned printing parameters, and collaboration with software and polishing companies to provide a complete solution from design to final part. Xact Metal's 3D printers complement traditional manufacturing processes by offering cost-effective solutions for producing small inserts and complex geometries that [...]

An Overview of Nexa3D- CimCast

An Overview of Nexa3D- CimCast In our fourth episode of CimCast, we discuss one of Cimquest's vendors, Nexa3D.

Enhancing Mastercam with Verisurf’s Universal CMM

Enhancing Mastercam with Verisurf's Universal CMM Join Cimquest and Verisurf as we explore the ins and outs of CMMs or Coordinate Measuring Machines.