Tips for Creating Your 3D Printable Ornament

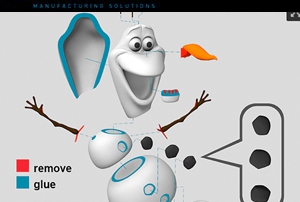

We hope you’re beginning the brainstorming and design process for your very own 3D printable ornament. The sky is the limit for what you can dream up and some questions have started to roll in. We thought we should share some of the answers with everyone to help you all in your design process. The biggest question that has come up is regarding colors. Some folks have asked, “Can my ornament be printed in multiple colors?” We have a two-part answer to this color question. The short answer is yes. But the long answer is that multiple colored designs will require you to submit the ornament file as individual solid bodies, one for each color. This sample of the "Olaf the Snowman" ornament consisted of 11 separate bodies within the STL file. Bodies were printed separately, allowing for different colors to be assigned to each piece. Another question regarding color, “What colors can my ornament be printed in?” We have a total of 9 colors available for ABS Plus and they are shown below. Please create your solid file in a color that closely represents one of these choices if you have a preference in the color. And the last question is regarding the [...]

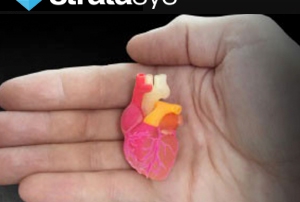

3D Printing is a Game-Changer for Infant Heart Surgery

OpHeart, a nonprofit organization that aims to provide the best possible care for children born with life-threatening heart defects, has become a crusader for normalizing 3D printing medical practices across health care institutions. OpHeart’s founder, Anne Garcia, is spearheading fundraising efforts for patient trials and protocols to demonstrate the clinical and economic benefits of 3D printing. Additive manufacturing has propelled advancements and has had life-changing impacts in the medical industry, resulting in improved and personalized patient care. Using Stratasys’ PolyJet 3D printing solutions, surgical teams can reproduce anatomical models that are derived from patient imaging and use those replicas to evaluate the best possible course of action for complex surgeries. Evaluation prior to surgery can increase the success of the operation and shorten the time in the operating room. Aaron Minard of EngATech presented Garcia with a Stratasys 3D printed heart model at a recent fundraiser event for OpHeart. Aaron Minard of EngATech presented Garcia with a Stratasys 3D printed heart model at a recent fundraiser event for OpHeart 3D printed models also serve as educational tools for medical students and offer low-cost solutions without compromising quality or accuracy. “To have something in your hand and be able to turn it any way you want [...]

3D-Printed Bone Cast Doubles as Bluetooth Speaker

Medical casts are getting a whole lot smarter thanks to the BoomCast, a 3D-printed cast with sensors and electronics onboard to help doctors better track the healing process and provide improved mobility. Some of the components that went into the BoomCast, before everything was put together. Fathom The BoomCast project was conceived of by Mike North, perhaps best known for his role on the Science Channel's "Outrageous Acts of Science" or his "In The Making" YouTube series. North broke his leg celebrating the life of his best friend Dan Fredinburg, the Google executive who was killed in an avalanche on Mount Everest back in April. When North, a frequent traveler who's highly active, was fitted for a cast, his doctors gave him two options. Either he could be fitted with a walking cast that allowed him to move freely but not be able to travel due to potential swelling, or they could cut the cast in half to eliminate swelling issues, but he'd be bound to crutches. And here's the finished product on Mike North's foot.Fathom Neither option sounded pleasant to North, so he turned to the folks at Fathom Studio, a 3D-printing and additive-manufacturing company, for help. Over the [...]

Top 3 Ways 3D Printing is Transforming Aircraft Interiors

3D Printing is transforming aircraft interiors in many ways. Designing and manufacturing for aircraft interiors hinges on weight reduction. To reduce weight, cutting down on material and additives is key. 3D printing allows for the creation of continuous units, meaning all necessary features are consolidated into one part thereby reducing material usage, additional hardware and attachment features, and overall weight. 3D printing began factoring into the production of interior aircraft components over a decade ago. Air ducts, wall panels, and seat framework have all benefited from the ability to create complex geometries and organic shapes for reduced weight with 3D printing. As more and more airlines seek to add seats or increase passenger space, 3D printing offers a way to simplify parts and thin down panels, overhead compartments and seat components. Here are the top 3 ways we see 3D printing transforming aircraft interior manufacturing: Less Material Usage 3D printing is an additive process, meaning it adds material layer by layer to build a final part rather than subtracting from a block of material. In a conventional process, a tool might be machined, then injected with material to pop out a final part. This scenario requires two tools for each side of the [...]

Take the Cimquest 3D Printing Ornament Challenge

This holiday season Cimquest is hosting a fun competition to get your creative juices flowing. We challenge you to design your own 3D printable ornament for a chance to win some great prizes. Tis the season to give your friends, family and loved ones a meaning gift and what could be better than a gift that you designed? This is your chance to create something unique and meaningful and, if you win, you will get your special ornament printed and delivered right to your door for free. All you need to do is get designing. Get creative. Use your favorite tradition as inspiration and create an ornament that is fun, festive, and unique to you! There are just a few rules that you need to follow: You need to submit your design to Cimquest by December 18, 2015 via email to contest@cimquest-inc.com. Please post a screen shot of your part on either Facebook or Twitter and tag it with #CQ3DPrintedOrnament. Your file must contain a watertight solid: Native CAD or Neutral File Format (SAT, STEP, IGES, X_T) Cimquest will use an internal vote to narrow the field down to 5 ornaments. The top 5 designs will be posted to our Facebook and Twitter pages. [...]

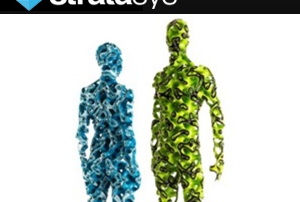

3D Printed Art Collection Explores Futuristic Human Form

Acclaimed artist and designer Daniel Widrig is collaborating with Stratasys to create a futuristic 3D printed art collection. The collection, entitled Descendants, was unveiled at the ‘GLOBALE: Exo-Evolution’ exhibition, which was held at ZKM | Center for Art and Media, Karlsruhe, Germany. DESCENDANTS by Daniel Widrig in collaboration with Stratasys produced using Stratasys’ PolyJet 3D printing technology. Size: 1751 x 452 x 292mm (Female), 1848 x 627 x 342mm (Male). Photo credit: Yoram Reshef Exploring a futuristic context where technological development and computational capacities continue to spiral, Descendants addresses the increasing possibility of superior artificial intelligence and technological singularity, and how future synthetic bodies might look and feel. “With advanced technologies, such as 3D printing, already facilitating the customization and enhancement of the human form, the concepts of a post-human era of non-biological intelligence is now much more conceivable,” explains Widrig. “It is an inevitable yet exciting design challenge to begin to speculate on how new material bodies might be formed to face the real-world constraints of the future.” The elaborate humanoid figures were developed by overlapping high-resolution 3D scans of male and female figures with intricate digital compositions. Bringing the digital images to life, the pieces were 3D printed using Stratasys’ color, [...]