Redefining Patient-Specific 3D Design

Redefining Patient-Specific 3D Design From Scan-to-NC: Reverse Engineering for CAM Applications Experts from Oqton and Cimquest showcase two powerful, organic design workflows using Freeform, 3D design software for organic models.

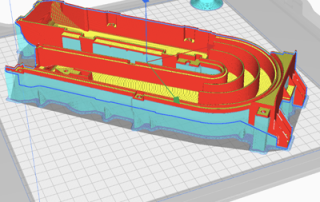

Breaking the Mold – Xact Metal for Tooling (WOD)

Breaking the Mold – Xact Metal for Tooling Join Cimquest and partner, Xact Metal, as we elaborate on the benefits of Xact Metal's 3D printers and how they provide for a greatly innovative tooling workflow. We will educate attendees on tooling, its various applications, Xact Metal's capabilities in surface finish, tolerance, and materials, return on investment (ROI), and thinking differently.

How 3D Printing Revolutionizes Orthotics

The traditional process for creating orthotics has fallen into an “if it’s not broken, don’t fix it” category of procedures. Characterized by high labor and time demands, traditional workflows produce orthotics that patients expect, but with added costs, indicating significant room for improvement. Digital workflows for custom orthotics encompass new design, testing, and manufacturing options to reduce customization costs and speed up production cycles for lower lead times, better-fitting devices, and improved patient outcomes. Known for its rapid production and relatively affordable processes, 3D printing provides stakeholders in the orthotics industry with a powerful solution that delivers customizable orthoses quickly and inexpensively. Traditional vs. 3D Printed Orthotics Orthotic devices are manufactured in a variety of ways depending upon the end-use part. Traditional manufacturing processes, including plaster casting, impression foam casting, conventional machining, thermoforming, and wax casting, may be utilized for manufacturing orthosis. Despite which methods are utilized, the basic workflows can be summarized as follows: A map of the patient is created through an impression or cast, technical drawings, and measurements. This can take up to one hour to complete. A developmental model is created from the topographical map. Depending on the process used, this can take from one to two hours. The [...]

Desktop Metal and Evonik Recently Expand Partnership

Companies report qualification of photopolymer on large-format additive manufacturing 2.0 systems. A reprint from Digital Engineering247.com Evonik INFINAM ST 6100 L printed on ETEC hardware from Desktop Metal is made for production of molds, models and tooling. Image courtesy of Business Wire. Desktop Metal and Evonik, a materials provider in 3D printing technology based in Germany, report their expanded collaboration on photopolymer and materials development with the qualification of INFINAM ST 6100 L on the ETEC Xtreme 8K and the Pro XL. Evonik INFINAM ST 6100 L is a benchmark material in high-strength photopolymers for 3D printing. With a tensile strength (UTS) of 90 MPa, flexural stress of 135 MPa, and heat deflection temperature (HDT) of 120°C, the material reportedly also delivers accuracy, surface finish, and resistance to many chemicals and UV degradation. Desktop Metal’s ETEC brand for polymer 3D printing is vested in digital light processing (DLP) hardware and a curated portfolio of additive manufacturing materials. “Desktop Metal is delighted to add Evonik and its INFINAM material to our highly selective portfolio of polymers, as we continue to offer customers the flagship material solutions in each performance class, ranging from stiff rigid plastics to high strength-to-weight ratio elastomers and foams,” [...]

Cura Now Supports UltiMaker Method Series 3D Printers

A year after the merger of Ultimaker and MakerBot, they have unlocked the ability for users of the Method series 3D printers to slice files using UltiMaker Cura. As of this release, users can find profiles for the Method X and Method XL printers, as well as material profiles for ABS-R, ABS-CF, and RapidRinse. Meaning it’s now possible to use either Cura or the existing cloud-slicing software CloudPrint when printing with these printers or materials. Why use Cura instead of CloudPrint? If CloudPrint meets your requirements, then there is nothing stopping you from continuing to use it. However, there are some distinct advantages to using Cura instead. Local slicing For companies with strict security policies in place, locally installed software that does not require internet access to operate is sometimes preferred over cloud-based software. In cases where CloudPrint is not an option, Cura can now provide a secure local alternative. Extensive settings selection. Cura has always provided users with access to a large number of settings and this release extends those options to Method series printers. In CloudPrint, the setting selection was limited to provide a controlled and repeatable printing experience, with the Labs extruder unlocking additional settings for users who wanted to [...]

3D Printing With Formlabs Silicone 40A Resin

Formlabs Silicone 40A Resin utilizes patent-pending Pure Silicone Technology™ and Formlabs’ stereolithography (SLA) ecosystem, enabling the in-house production of 100% silicone parts in a matter of hours. It is ideal for applications requiring pliability, durability, and resistance to repeated stretching, flexing, or compression. The applications for Silicone 40A Resin are diverse, ranging from rapid prototyping, beta testing, and validation stages in product development to cost-efficient low-volume or custom manufacturing of end-use parts. The material is also suitable for manufacturing medical devices, patient-matched prosthetics, audiology components, and for the production of parts with complex geometries that are challenging to manufacture through traditional methods. The introduction of Silicone 40A Resin addresses longstanding challenges associated with traditional silicone 3D printing methods, such as high costs and technical limitations. One-touch printing with Silicone 40A Resin saves time by eliminating the need to design and manufacture molds, and pour and cast silicone. It also opens up design possibilities by enabling the users to create complex geometries that are difficult to achieve using traditional manufacturing methods. This accessible solution allows businesses to create high-quality end-use parts without compromising on price, quality, or speed. For more information on Formlabs 3D printing materials, please click below. More Details