3D Printing With Formlabs BioMed Resins

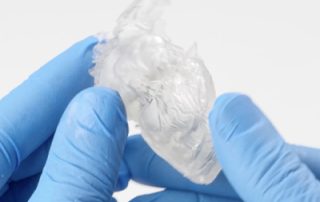

Introducing Formlabs BioMed Flex 80A Resin and BioMed Elastic 50A Resin Formlabs is excited to introduce two novel materials designed for the direct 3D printing of elastomeric, biocompatible medical devices and models: BioMed Flex 80A Resin and BioMed Elastic 50A Resin. These new materials represent a significant expansion in medical application areas, particularly in the realm of anatomical modeling. Traditionally, professionals looking to create soft anatomical models have grappled with the challenges of multi-step silicone molding processes, labor-intensive procedures resulting in limited geometries, messy outcomes, and excessive time and money spent. Alternatively, they have settled for costly contract manufacturing or rigid models. Enter BioMed Flex 80A Resin and BioMed Elastic 50A Resin, which offer healthcare professionals the unprecedented ability to merge the advantages of traditional elastomeric and biocompatible materials with the user-friendly experience and streamlined workflows inherent to Formlabs resin 3D printers. Why Use Soft Anatomical Models? Soft anatomical models offer a great value to healthcare providers and patients alike. As cases become more complex, and interventions more unique, anatomical models can be used by healthcare providers to map pathology, plan interventions, gain a three-dimensional understanding of anatomical spatial relationships, pre-fit medical equipment, and practice approaches, all before the patient enters the operating [...]

Cimquest is Excited to Attend AMUG

On March 10-14, Dave Macfie, Jim Snodgrass and Greg Wilkman will be attending the Additive Manufacturing Users Group (AMUG) Conference in Chicago once again! The purpose of AMUG is to educate and advance the use and applications of all additive manufacturing technologies and the cornerstone is the annual Education & Training Conference. Cimquest is both excited and proud to be going to this premier networking event and will be participating in several new ways in addition to previous years' contributions: Dave Macfie is a Co-Track Leader at this year’s AMUG conference. Since August, he’s been busy helping to set up and organize the presentations, panels and workshops for the metals track. Most likely you will see him in the Continental B conference room on the lobby level (wearing one of his new AMUG shirts!) making sure his speakers, panelists, and moderators are good to go. Jim Snodgrass will be leading one of those panel discussions; Application of Metal Printing for Tooling taking place on Monday, March 11th from 4:30 PM - 5:30 PM. While metal 3D printing was once a niche manufacturing process reserved for producing only the most high-value aerospace and medical device components. Today, it has evolved into dozens of different [...]

The Virtual Edge Deviation Tool

This blog post will discuss how to use the Virtual Edge Deviation Tool in Control X. It is often necessary to extract virtual edges of a part to compare them to the actual CAD model’s edge to ensure a part is within spec. Depending upon the resolution of the scanner, the sharp edges of a scanned part may be somewhat rounded or chamfered. Consider the requirements of checking the outer edge of the part shown below to ensure it aligns properly with the mating part. In this post, we will explore running a Virtual Edge Deviation Analysis around the outer perimeter of the part. CAD MODEL – Actual Sharp Edge SCAN – Edges are rounded due to the scanner’s point spacing (aka resolution) The virtual edge of the mesh would be where the thin rib top and outside walls of the manufactured part would meet, if extended. In the image below, we are showing the scan and CAD model after alignment. The red arrows are pointing to the flat surfaces that would be extended to determine the theoretical edge of the scan surface so it may be compared to the CAD model’s nominal edge. Virtual Edge Deviation – Shown as a whisker plot [...]

Formlabs Fuse Series 3D Printers Records Fastest Print Time Ever

Not Only Did the Fuse Series 3D Printers Record the Fastest Print Times But SLA Reaches New Heights Formlabs’ most recent software update, PreForm 3.34.0, introduces several features that can unlock new printing capabilities for both stereolithography (SLA) and selective laser sintering (SLS) workflows. With these updates, the Fuse 1+ 30W makes fast, daily production of full builds possible — print speeds are 25% faster than with previous software, and over three times as fast as original Fuse 1 print times. Now, 95% of fully packed Nylon 12 Powder print jobs will be completed in less than 14 hours, and typical builds will finish in just seven hours. In addition to the 25% speed improvement for the Fuse Series, new build volume parameters for the Form 3 Series increase available height by 4% for desktop and 7% for benchtop SLA, and new workflow updates demonstrate our commitment to continuous improvement for both our powder and resin printing ecosystems. Constant iteration is not just something that 3D printing enables for our customers, but something that we know is necessary for any successful product, including our own. By listening to and incorporating feedback, Formlabs is working to ensure that our printers are powerful, reliable tools [...]

Mastercam Announces the Signing of an Agreement to Acquire Cimquest

I’m excited to announce that Mastercam, in conjunction with Sandvik, has announced the signing of an agreement to acquire Cimquest. This is a natural next step for our Cimquest organization to allow us to expand our technology and support to become more accessible to Mastercam users in the Northeast region of the United States. It is important to note that there are no plans to change relationships with any of our external vendors, customers, or support solutions as a result of this acquisition. We will continue to offer our premier technology and support to our customers. I will be the Vice President, of Integrations and Owned Entities at Mastercam, and Shawn Crews will be the Managing Director of Cimquest. Shawn will act as the liaison between Cimquest and Mastercam; he will also ensure continuity of services and operations for our customers throughout the transition and beyond. Cimquest adds talent, operational efficiency, and diverse perspectives to Mastercam’s ecosystem of solutions. The acquisition allows Cimquest to focus on what we do best: serve our customers! More details on the announcement of the signing of the acquisition’s press release can be found here (Sandvik Announcement). In closing, we are grateful to be part of this fantastic [...]

Working With the Shining 3D FreeScan UE Pro

Today we are going to talk about working with the FreeScan UE Pro laser handheld 3D scanner, brought to you by Shining 3D. Just as CNC machine tool and 3D printer manufacturers design products to address different part sizes, materials, etc. scanners are no different. It takes the expert staff we have at Cimquest to offer guidance and direction for users tasked with choosing the scanning solution that best fits their metrology and reverse engineering requirements. The FreeScan UE Pro is a high-precision, metrology-grade laser scanner. While providing an incredible capability for fine-feature scanning using its 5-laser line mode, it also improves the global position control for large-scale, workpiece scanning by deploying built-in photogrammetry. Among the many excellent characteristics, the UE Pro can scan normal, reflective, and even black parts and can do so all within the same scanning project. Therefore, for parts of varying size details and made up of varying textures (shiny metal, black tubes, etc.), the UE Pro is an excellent selection as it can adapt quickly to these different scanning requirements and challenges. There are three laser controls. The main scanning environment utilizes 26 crossing lasers for getting through large scanning projects very quickly. The 5 parallel laser line [...]