Meltio Additive Manufacturing Technology Recieves Awards

The U.S. Department of Defense has awarded the unique and patented metal 3D printing technology of the Spanish multinational metal additive manufacturing leader solutions Meltio, which means the recognition as a “strategic technology partner” in the current and future development plans of that country in the military and security field. This is the first time that a Spanish company has received this award in the field of additive manufacturing, which allows printing and repairing parts using 3D printing, solving possible logistical problems and providing manufacturing autonomy, and improving the supply chains of parts in the defense sector. This award consolidates Meltio’s relationship with the U.S. Army and increases its possibilities of having a relationship with other U.S. defense departments and also with armies of other countries. Meltio’s goal is to become a technological reference in 3D printing of metal by welding wire (known as DED, directed energy deposition for the creation of metal parts layer by layer by laser fused deposition). Ángel Llavero López de Villalta, CEO of Meltio, said: “The award we have received is a recognition to Meltio’s professionals and gives reliability to our technology. For us, the military sector is a sector that allows us to bring together all the [...]

Formlabs is Expanding Their 3D Printing Materials

Formlabs has recently expanded their 3D printing materials library. Their mission is to expand access to digital fabrication, so anyone can make anything. This mission has led them to create new resins like their Flame Retardant Resin and BioMed Durable Resin which have expanded the capabilities of Formlabs' SLA printers. Now, Formlabs has created two new Resins that will change the game for a lot of applications. Introducing Alumina 4N Resin and Silicone 40A Resin. Alumina 4N Resin is a high-density and high-purity technical ceramic 3D printing material with exceptional performance in extreme environments: thermally resistant, hard, abrasion resistant, mechanically strong, and chemically inert. Embrace the future of ceramic engineering with the most affordable ceramic 3D printing ecosystem in the world. Introduce the power of 3D printing to manufacture your advanced ceramic components without expensive tooling, and reduce production costs and lead times while increasing design freedom. Silicone 40A Resin is the first accessible 100% silicone 3D printing resin. Eliminate molding and labor-intensive casting processes: Silicone 40A Resin uses Formlabs’ patent-pending Pure Silicone Technology™ to 3D print pure silicone parts in-house, in a matter of hours. Combine the high performance of silicone and the design freedom of 3D printing to create highly functional [...]

Desktop Metal Qualifies Copper Alloy C18150 for 3D Printing

Desktop Metal partners with global automotive manufacturer and leading material supplier to qualify Copper Alloy C18150 Copper is a highly sought-after, versatile material in metal additive manufacturing, as it can be used in a wide range of applications, from electrical conductors to welding tips, and in more recent investigations as combustion chamber liners. Combining the benefits of 3D printing, such as new design freedoms, with the material properties of copper opens new possibilities and demand for the fabrication of thermal control components. Desktop Metal, in partnership with a global automotive manufacturer and Sandvik Osprey, has qualified binder jetting copper alloy C18150 on a Production System™ P-1 research-and-development system for a production component. Finding the Right Copper Pure copper can be a challenging material to process to high density with the binder jetting process, though many customers desire to take advantage of the geometric freedom and lower costs of 3D printing this conductive material. Copper alloy C18150 uses chromium and zirconium as the primary alloying elements to offer a unique combination of exceptional physical and mechanical properties. The high-performance alloy delivers the strength and hardness, together with the outstanding electrical and thermal conductivity, that many customers seek for thermal transfer applications. The material is [...]

Revolutionizing Mold Making with 3D Printing

Meltio is combining Laser Metal Deposition (LMD) and Dual Wire 3D printing techniques to revolutionize mold making. We're thrilled to introduce you to a game-changing resource that's poised to redefine mold making as we know it. Meltio 3D is proud to present their latest whitepaper, "Mold Making with LMD and Dual Wire". This comprehensive document delves into the convergence of cutting-edge technologies that are reshaping the manufacturing landscape. By combining Laser Metal Deposition (LMD) and Dual Wire techniques, they're revolutionizing mold creation with unparalleled precision and efficiency. Key Highlights of the Whitepaper: In-depth exploration of Laser Metal Deposition (LMD) and Dual Wire technology. Real-world applications and case studies showcasing the transformative impact on mold making. Insights into the synergy between technology and craftsmanship, fostering innovation. Expert perspectives on the future of manufacturing and its limitless potential. We invite you to access the whitepaper by clicking the button below. Whether you're a seasoned industry professional, an academic enthusiast, or simply someone curious about the forefront of innovation, this whitepaper promises valuable insights into the future of mold making. Download the Whitepaper

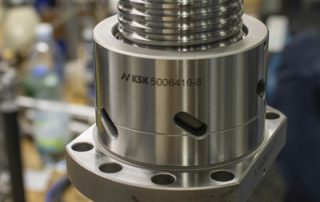

Xact Metal 3D Printing Case Study – Alternative to Casting

The Customer KSK Precise Motion, an engineering company from Kurim, Czechia, has been producing and distributing ball screws, among other precision components, around the world for 50 years. With 120 employees involved in the production of ball screws, which are used in a wide range of industrial areas, such as machine tools and injection molding machines, as well as in the automation and energy sectors, KSK Precise Motion is a globally sought-after partner for machine and equipment manufacturers. When they approached Xact Metal with a request for 3D-printed end parts for a specific nut for a ball screw, we knew it was an exciting opportunity for us to collaborate with a respected industry leader. The Project The company’s goal was to optimize production speed, and they had three requirements for any 3D printed components to be accepted into their production. The first requirement was that the converter prints have highly accurate path geometry. A secondary, but no less important requirement, was that the quality of all parts must be repeatable. The solution also required the capacity for a large construction volume so many copies could be printed at once and delivered in a short time. The project began by designing the geometries for [...]

3D Printing of Large Injection Mold Inserts and Test Parts with Formlabs

These test snout parts, designed by mechanical engineer Brian Biller at the Siemens Energy Orlando Innovation Campus, interface with gas turbine vanes in an airflow testing rig. The Siemens Energy’s Orlando Innovation Campus (OIC) develops and executes concept-to-completion projects for partners in industries across the world. Engineers there have access to every industrial tool available; they’re tasked with combining manufacturing technologies like machining, molding, automation, and 3D printing to solve global problems. Additive Manufacturing Technician Matthew Deutsch is responsible for their additive manufacturing (AM) composites department, managing a fleet of fused deposition modeling (FDM) and stereolithography (SLA) printers, including two Form 3L benchtop SLA units. Deutsch relies on the versatility of the Formlabs materials library to develop everything from rapid prototypes to injection mold inserts, and worked with Formlabs to help validate the new game-changer in the post-processing workflow for large-format SLA parts, the Build Platform 2L. Leveraging the patented Quick Release Technology of Build Platform 2L, Deutsch has been running his Form 3L printers nonstop, and has started printing larger parts like molds and manufacturing aids directly on the build platform. "The wait was worth it. With molds, we can print and then start pumping out injection molded plastic parts within 24 [...]