These test snout parts, designed by mechanical engineer Brian Biller at the Siemens Energy Orlando Innovation Campus, interface with gas turbine vanes in an airflow testing rig.

The Siemens Energy’s Orlando Innovation Campus (OIC) develops and executes concept-to-completion projects for partners in industries across the world. Engineers there have access to every industrial tool available; they’re tasked with combining manufacturing technologies like machining, molding, automation, and 3D printing to solve global problems.

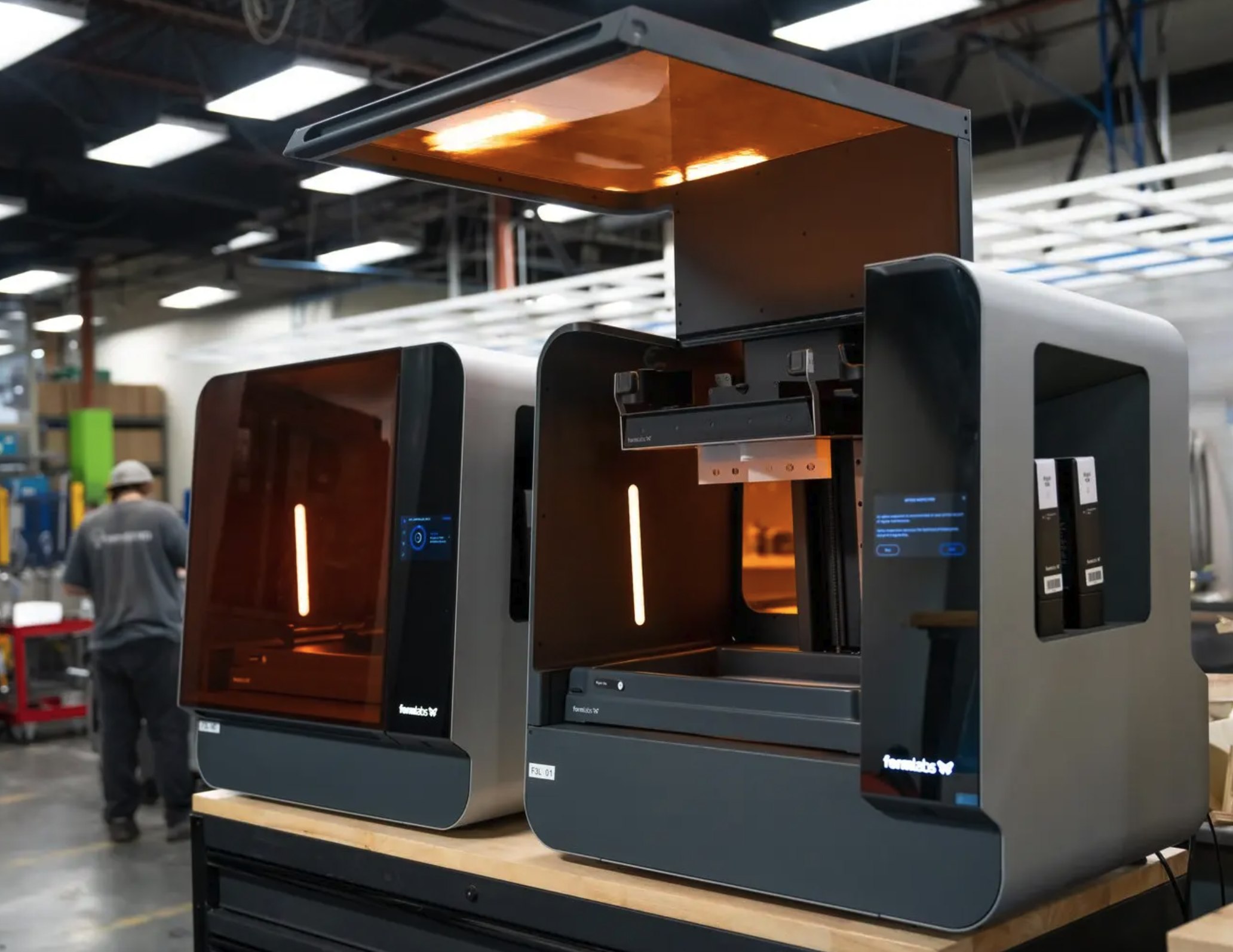

Additive Manufacturing Technician Matthew Deutsch is responsible for their additive manufacturing (AM) composites department, managing a fleet of fused deposition modeling (FDM) and stereolithography (SLA) printers, including two Form 3L benchtop SLA units. Deutsch relies on the versatility of the Formlabs materials library to develop everything from rapid prototypes to injection mold inserts, and worked with Formlabs to help validate the new game-changer in the post-processing workflow for large-format SLA parts, the Build Platform 2L.

Leveraging the patented Quick Release Technology of Build Platform 2L, Deutsch has been running his Form 3L printers nonstop, and has started printing larger parts like molds and manufacturing aids directly on the build platform.

“The wait was worth it. With molds, we can print and then start pumping out injection molded plastic parts within 24 hours. This is a genesis for the entire industry.” – Matthew Deutsch, Additive Manufacturing Technician at the Siemens Energy Orlando Innovation Campus

3D Printing Assists in Dealing in Emergencies

Since bringing in the two Form 3L printers and educating other departments about the versatility of SLA 3D printing, Deutsch says the printers have been running almost non-stop.

The types of requests coming into the AM department range from models of engines for trade shows to fixtures and tools critical in repairing gas turbines halfway across the world. “We deal in emergencies. Siemens Energy will come to us with a request to develop processes to repair components of an engine, sometimes during an outage — a planned or unplanned period of time in which the engine is disabled. Every minute that engine isn’t producing electricity, that’s a huge loss. One 3D printing project assessed the wear and tear on turbine blades to avoid future power outages,” says Deutsch.

Having multiple 3D printers and a variety of materials helps get those projects completed quickly. Deutsch was responsible for bringing SLA technology to the OIC, and at first, his colleagues were wary of resin materials. As they saw the advantage of having such a versatile material library, his colleagues began exploring new ways of incorporating SLA parts into their workflows. Now, Deutsch is seeing more requests for parts on the Form 3L than any other printer. “I’ve been receiving fewer requests for the other technologies and more requests for resin parts, anything from Rigid 10K Resin for injection mold inserts to Tough 2000 Resin and Clear Resin. Those machines haven’t turned off,” says Deutsch. Tough 2000 Resin has been a staple for the team because of its strength and stiffness. They’ve been using it as an aluminum analog in parts like airflow snouts that require strength and airtightness.

The material variability of Formlabs SLA product line means that there’s a solution for almost any problem. Given the global scale of the Siemens Energy network, a tool that enables different workflows is a huge advantage. “Every request is different — it’s never the same week twice. The Form 3L’s ability to pivot like that is unmatched,” says Deutsch.

Leave A Comment