Xact Metal New XM300G Mid-Size Affordable High Performance Metal Printers

Aiming to bring affordable metal 3D printing to small- to medium-sized companies and decentralize metal 3D printing, Xact Metal™ recently announced the launch of the XM300G series of affordable mid-size metal 3D printers. “With pricing beginning at a US MSRP of $200,000 dollars, the XM300G series is ideal for printing high quantities or large parts where print speed is critical,” said Juan Mario Gomez, CEO of Xact Metal. “Based on the XM200G multi-laser printer platform, the introduction of the XM300G is another example of how Xact Metal continues to combine the requirements of metal powder-bed fusion and advanced technology to establish a new level of price and performance for additive manufacturing.” The XM300G family is a single-, dual-, or quad- independent laser system with 100% overlapping print zones that introduces industrial speed and performance at an affordable price, allowing small-to-medium companies to benefit from metal laser powder-bed fusion technology. A large 300 x 300 x 350 mm build volume, upgradable to 300 x 300 x 450 mm, a selection of 400W or 700W fiber lasers, and an interchangeable build platform to reduce printing cycle time, make the XM300G well-suited to support a wide variety of additive manufacturing applications. Xact Metal has already received [...]

October 3D Printing Tech Tour

We have another exciting opportunity for you to experience 3D Printing. On October 20, 2022, you can visit the ABCorp in Boston, MA to learn about 3D advancements and how Multi Jet Fusion (MJF) technology is reshaping how businesses approach digital transformation. We are joining forces with HP and ABCorp for this informative event. Participation is free and light refreshments will be provided but registration is required. Secure your spot today! Event Date October 20, 2022 2:30 - 5PM Agenda Speakers Register today by clicking below. Register Here

Desktop Metal Upgrades Live Sinter™ Software

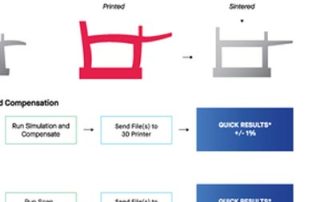

Desktop Metal Announces Upgrades to its Popular Live Sinter™ Software, a Powerful Multi-Physics Simulation Tool that Delivers Trusted Results Live Sinter simulation software predicts and corrects for shrinkage and distortion in metal parts 3D printed with binder jetting technology. Sinter-ready, printable geometries are provided in as little as 20 minutes and deliver highly accurate final part results. (Graphic: Business Wire) Desktop Metal, Inc. (NYSE: DM), a global leader in additive manufacturing technologies for mass production, recently announced significant updates to Live Sinter — a powerful multi-physics sinter simulation software application that automates the generation of sinter-ready, printable geometries, as well as supports, setters, and inserts, to make repeatable, volume production of high-precision end-use metal parts through binder jetting more accessible. Launched in the fall of 2020, Live Sinter is now trusted by users at more than a hundred companies globally, and the software is a key enabler of Desktop Metal’s AM 2.0 binder jetting solutions, making them easier to adopt and ramp to production for customers without any prior powder metallurgy or sintering expertise. Live Sinter’s powerful multi-physics simulation and compensation software delivers sinter-ready, printable geometries that maintain tight shape and dimensional tolerances. After scan-based adjustments, Live Sinter enables correcting for [...]

XYZ Printing SLS Machines Offer a Greener Professional 3D Printing Solution

XYZ Printing’s SLS machines can be used to reduce waste and provide more cost efficiency, making additive manufacturing greener. (Sponsored Content) Fully Recycled PA12 Part from mixed MJF and SLS waste, XYZ MfgPro236, MfgPro230 All forms of 3D printing provide incredible value in terms of innovation, speed, communication, and customization. This novel technology’s advantages have outweighed the downsides, such as cost, electrical usage, and hazardous and non-hazardous waste. SLS technology reduces waste by using essentially reusable thermoplastic powders. However, depending on the platform you select, the critical factor of recycling material remains. Some SLS machines have material recycling efficiencies as high as 80/20 (meaning the refresh rate is only 20% for un-sintered powder). Others require fresh powder at a rate of 50%, and these tend to be large-format machines that print larger parts. Hazardous or not, it presents a significant issue of end-of-life powder waste for machine owners, especially those working with multiple machines. Service bureaus and businesses with more than five large-format SLS and or MJF machines face a storage dilemma as the wasted powder stacks up. How much do they have to pay for disposal, and what is the environmental impact? Despite the advantages SLS 3D printing provides over [...]

Metrology Minute – Geometry Deviation

When considering analytic 2D and 3D features, Control X can return a lot of useful information from manufactured features on an aligned scan. For example, when considering cylinders (holes) in a manufactured part (3D Printed, machined, etc.), Geometry Deviation analysis can return essentially all of the pertinent data required for manufacturing in terms of measuring location, size, and orientation. In the example of the gas valve below, the scan of the machined part was already aligned to its nominal CAD model. Shown below are the results when analyzing two cylinders on the part for size, location, and orientation. The “paired” values are provided from the scan and actual values are provided from the nominal CAD model. The deviation values show the centerline deviation of the scan to the nominal CAD model in the three directional axes as well as the “Dev” value, which is the ‘as-the-crow-flies’ deviation, from scan to CAD model. For planes, the compelling information provided in the Geometry Deviation analysis is the normal vector and how the scan differs from the nominal model. 2D information is available as well through Geometry Deviation. The image below shows analyzing the scan of a circle on the part as compared to the nominal [...]

Desktop Metal Expands 3D Printing Lineup

Desktop Metal Expands Lineup for World’s Best-Selling Metal Binder Jet System with Shop System+ and Shop System Pro Desktop Metal today announced two upgrade packages on its Shop System™, offering new flexibility, functionality, and value for the world’s best-selling metal binder jet system. The Shop System+ and Shop System Pro offer power users new options for materials and controls. (Photo: Business Wire) Desktop Metal recently announced two upgrade packages on the Shop System, offering new flexibility, functionality, and value for the world’s best-selling metal binder jet system. First unveiled in November 2019, the Shop System was designed to bring metal additive manufacturing to machine and job shops with an affordable, turnkey solution that achieves exceptional surface finish parts with rich feature detail at speeds up to 10 times those of legacy powder bed fusion additive technologies. To date, Shop System users worldwide have logged more than 20,000 print hours. Now, Desktop Metal is expanding the lineup of this successful platform with the Shop System+ and the Shop System Pro, giving power users more flexibility and control over operating costs and machine parameters. The Shop System+ package enables high-production users to access Desktop Metal-engineered powders and binders at a discount, reducing the [...]