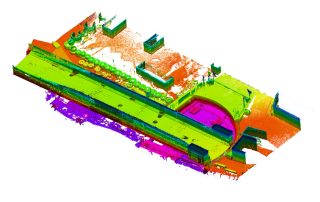

Swing Bridge Reverse Engineering Simplified with Geomagic Design X

Swing Bridge Reverse Engineering Simplified with Geomagic Design X A swing bridge in a coastal dock system was decommissioned after being twisted. A ferry company needed it operational for car parking but faced a dilemma: closing the bridge to test it could jam it if it wasn’t functioning. Unable to test physically, they created a digital twin using a long-range laser scanner and simulated the bridge’s motion if closed. Scanning a swing bridge This approach, led by OR3D and Service Manager Robert Wells, used a Trimble X12 3D Laser Scanner to capture the bridge’s details and Geomagic Design X to create a CAD model for simulation. A two-person team completed 120 high-definition scans in one day. The data was checked in Trimble RealWorks and uploaded into Geomagic Design X, where Sean Kean modeled the bridge and its components. Accuracy of the essence Modeling and data processing took a few days due to complexity. “Once we modeled the bridge in Design X, we ran the simulations, and saw the bridge was going to collide in a certain position,” Kean explains. “That gave the company the confidence to try it for real.” The simulation predicted a two-to-three-millimeter collision, confirmed in real-life. “We wouldn’t have been [...]

What’s New with Shining 3D Scanners

What's New with Shining 3D Scanners Einscan HX and HX2 (Reverse Engineering) The HX is an excellent scanner for reverse engineering. For the scanning and reverse engineering of many part sizes and shapes, the Einscan HX (and soon, the HX2) are an excellent choice. Stay-tuned for HX2 info. when it becomes available. The HX and HX2 are hybrid scanners. While holding 40 micron total tolerance in laser mode, this scanner model can also scan using structured light and can capture color/texture. Freescan Combo | Combo Plus (Reverse Engineering and Inspection) Roughly the size of a cell phone, the Combo and Combo Plus are excellent for both metrology and reverse engineering. The Combo Plus offers roughly double the scanning speed over the Combo. These are both metrology-grade scanners, offering 20 micron accuracy and up to 50 micron resolution. When used in HD mode, these scanners can create a single scan with multiple resolutions captured. So when scanning an object that has a specific location with high detail, the Combo or Combo Plus is ideal for capturing both sets of features in a single scanning session. Additionally in IR mode, this scanner does an incredible job at scanning organic shapes and since it [...]

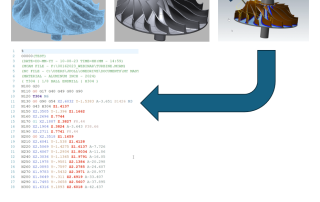

Design X Go – Reverse Engineering for Mastercam has arrived!

Design X Go – Reverse Engineering for Mastercam has arrived! The ‘Bridge’ from Scan or Point Cloud data to fully machinable models in Mastercam If you’ve ever programmed a Step file that was ‘AutoSurfaced’ from a mesh or point cloud, you’ve likely experienced the many challenges associated with this process. Design X Go supports traditional CAD modeling capabilities to generate the most basic, 2-axis part to the most involved, multi-axis part, from scan data. From Mesh to Part to Mastercam’s pocketing toolpath to ‘clean’ 2-Axis code! Same capabilities in the surfacing and multi-axis environment! From Mesh to Part to Mastercam’s Blade Expert toolpath to ‘clean’ 4-Axis code! Register for our Webinar on October 29th, 2024. 10:00 AM - 11:00 AM EDT to see how Design X Go can provide outstanding reverse engineering capabilities for designing and programming parts when you don’t have a CAD model. Register Today

HP 3D Printing and Cimquest: Innovating Custom Solutions for J-DAMMIT

HP 3D Printing and Cimquest: Innovating Custom Solutions for J-DAMMIT In September, Harrisburg University of Science and Technology (HU) and its Center for Advanced Manufacturing and Materials, STORMWERX, once again hosted the Joint-Defense Advanced Manufacturing Meeting for Innovation and Transition Summit, better known as J-DAMMIT. J-DAMMIT brings together experts from industry, academia, government, and the armed forces to explore and demonstrate cutting-edge manufacturing technologies that support defense needs. The event includes hands-on demonstrations in areas such as robotics, additive manufacturing, CNC machining, hybrid manufacturing (CNC and DED), augmented and virtual reality (AR and VR), and smart factory technologies. Through demos, collaborative discussions, and hands-on experiences, it’s a key opportunity for networking and learning about how these innovations can be applied to support military operations and the modern Warfighter, as well as the broader defense industry. The event took place at Harrisburg University, and offered hands-on opportunities focused in the UPMC Health Sciences Tower. The facility is HU’s newest addition to its campus: A state-of-the-art, 11-story, 260,000-square-foot education and research tower in downtown Harrisburg, Pennsylvania, which includes the University’s advanced manufacturing labs and reception spaces. The Project: Custom Sunglasses for J-DAMMIT Cimquest's Jim Snodgrass was involved in the planning and organization of J-DAMMIT and [...]

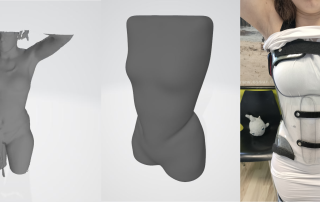

Advancing Orthotics & Prosthetics through Digital Innovation with Freeform

Advancing Orthotics & Prosthetics through Digital Innovation with Freeform Luca Gualerzi, a Certified Prosthetist and Orthotist (CPO), leads Ortopedia Gualerzi, a family business in Italy. Embracing digital workflows, they use Oqton Freeform for designing 3D models. Nobel88, their B2B arm, manufactures and trains other O&P companies. Despite early challenges, they now produce diverse medical devices, including spinal braces and prostheses, with Freeform’s help. A custom spinal brace for scoliosis correction, designed using Freeform from a 3D patient scan and produced with a milling machine. Gualerzi mainly utilizes Freeform to create milling files, with occasional use for 3D printing. Certified Prosthetists and Orthotists (CPOs) from all over Italy send scans to Nobel88, which are then transformed into manufacturable models. Each year, they process approximately 5,000-6,000 files using Freeform. Sculpting and CAD in one software Freeform bridges the gap between sculpting and CAD software, essential for O&P 3D design. Initially, Gualerzi tried Blender, Zbrush, and Meshmixer, but they lacked CAD capabilities. He also combined Rhino with Meshmixer or ZBrush, but found Freeform to be the most comprehensive solution. A leg prosthesis was designed using Freeform and 3D-printed on an HP machine with PA12 material. The entire process took under half a workday: [...]

HP 3D Printing Solutions: 3D Printing Performance Footwear

At HP, they believe thoughtful innovation can have a real impact on business, people, and the planet. Hp's 3D printing solutions enable more sustainable manufacturing across industries like automotive, healthcare, and consumer goods. Using 3D printing for final parts and prototypes is quicker, uses less energy, and creates less waste than traditional manufacturing. Last October, at HP Imagine, HP unveiled a new partnership with Brooks Running to disrupt the performance running footwear market. The first innovation from this collaboration is the Brooks Exhilarate-BlueLine running shoes, featuring 3DNA, a 3D-printed midsole technology. This technology delivers a propulsive, bouncy ride and is tuned to groups of sizes based on runner data for optimal cushioning and spring. Brooks will release a limited number of Exhilarate-BL pairs to select Brooks Wear Testers and Brooks Run Club loyalty members. Through wearables, Brooks can access runner data to inform future iterations of shoes featuring 3DNA. Nikhil Jain, director of footwear product line management at Brooks, highlights the precision and sustainability benefits of using HP’s 3D printing technology. HP’s 3D printing is also reimagining other industries. For instance, HP has partnered with Decathlon and Lonati Group to make shoe elements more sustainably. HP is working with Smith Optics to produce personalized snow [...]