Freeform Plus – Creating a Foot-Ankle Orthotic from a Human Scan- 2 Minute Tuesday

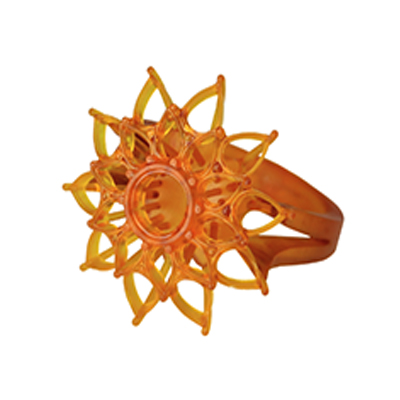

Freeform Plus – Creating a Foot-Ankle Orthotic from a Human Scan In this week's 2 Minute Tuesday, we explore how to design a foot-ankle orthotic using the scan of a human leg and Oqton's Geomagic Freeform Plus.