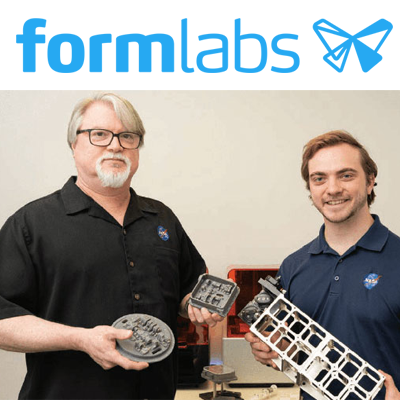

NASA Sends Formlabs Parts to Space

Reprint from Digital Engineering 247 Parts will ride aboard the SpaceX Dragon Resupply Capsule. Later in the summer of 2022, SpaceX will launch its 25th commercial resupply services (CRS-25) mission to the International Space Station (ISS). On board, the cargo capsule will be 4,500 pounds of food and equipment for the crew members on board the ISS. This mission is part of the ongoing cargo contract between SpaceX and NASA and involves collaboration and partnership [...]