Welcome to the Cimquest Blog!

Check here often to find Cimquest, Mastercam and 3D Printing happenings, product offerings and update info along with general Industry trends and breaking news.

March 2018

Lubrizol Introduces First 3D Printing Materials

(Reprint from https://www.tctmagazine.com)

Lubrizol, a specialty chemicals company, has introduced its first three 3D printing material products after its entry into the additive market.

The Ohio-based company has followed the likes of BASF, SABIC, and Clariant into the industry to offer its expertise, particularly in the development of thermoplastic polyurethane (TPU) materials, to those pushing AM from a […]

HP Unveils 4 Lower-Cost Jet Fusion 3D Printers

HP Inc. recently revealed the next evolution of its 3D printing business with the unveiling of four new Jet Fusion 3D printer models that will feature the same technology of the original models, but with a smaller footprint and lower cost to reach a broader set of customers.

The expanded Jet Fusion lineup will include models that can print full-color objects as well as models that just […]

February 2018

Metal 3D Printing for Injection Molding

Built-Rite Tool & Die, a Cimquest customer, is a mold-making and design firm based in Lancaster, MA. The company makes precision molds for use in a range of injection molding techniques.

The Desktop Metal Studio System has been tested by Built-Rite for the manufacture of several components of the Studio System metal 3D printer. These included a “flipper arm” used in the Studio System to “eject the bound metal or interface media rods […]

Form 2 3D Printer

Let’s take a fresh look at the Form2 3D printer from our friends over at Formlabs.

Stereolithography, more commonly known as SLA, is a 3D printing technology that originated in the early 1980’s.

With SLA, a liquid photopolymer is converted into solid material layer by layer when exposed to a highly concentrated […]

Upcoming PMI-Driven Inspection Seminar

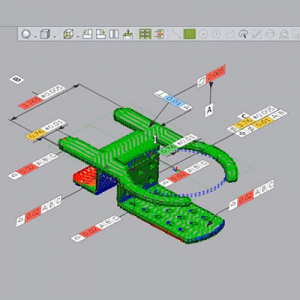

Join Cimquest for an in-depth look at PMI-driven inspection using CAD (SOLIDWORKS) and Geomagic Control X. In this workshop, you will see the seamless integration of Product Manufacturing Information from CAD driving a complete part inspection in Control X. By setting up PMI dimensions with tolerances, datums, GD&T, notes, labels, etc. in SOLIDWORKS using ‘Dimension Expert’, the inspection of the part then becomes fully automated.

Presentation topics […]

Using SolidWorks DimXpert for Final Inspection

SOLIDWORKS and Control X work really well together in the 3D part inspection world. SOLIDWORKS is one of the leading CAD tools in today’s design and manufacturing world. One of its advantages is that it offers you the opportunity to create a 3D annotated model. This can include things such as explicitly-specified dimensions, tolerances, 3D GD&T, surface texture symbols, finish requirements, and so on.