Let’s take a fresh look at the Form2 3D printer from our friends over at Formlabs.

Stereolithography, more commonly known as SLA, is a 3D printing technology that originated in the early 1980’s.

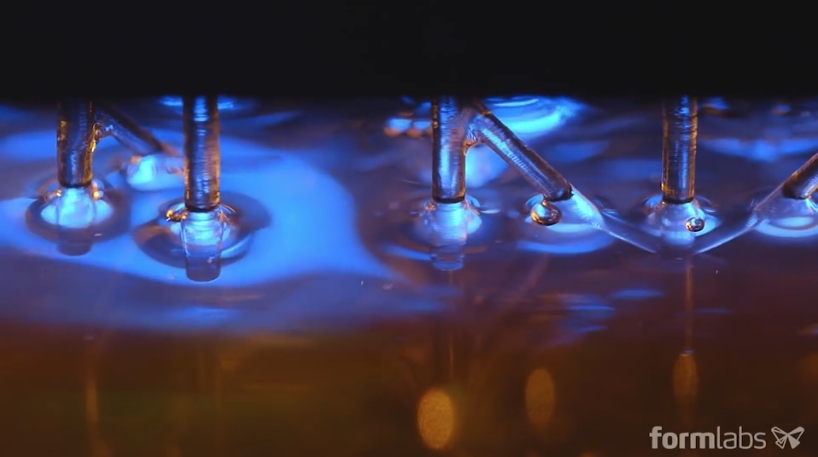

With SLA, a liquid photopolymer is converted into solid material layer by layer when exposed to a highly concentrated light source, such as a laser or projector, in a process known as photopolymerization.

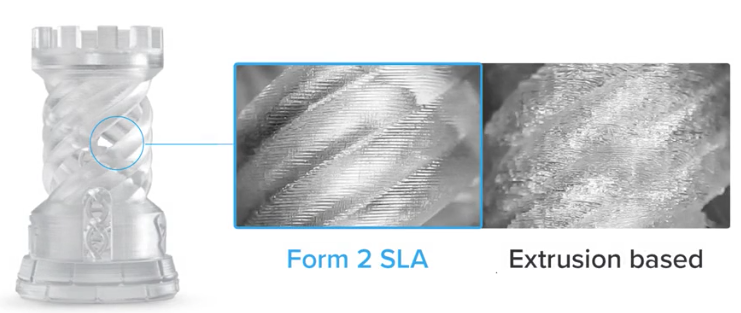

The result is a three-dimensional solid part that is water-tight with a smooth surface finish and fine details. Due to the high resolution, layer lines are less noticeable than parts fabricated with extrusion-based printers.

While SLA fits well into a variety of applications, large-scale industrial systems are expensive to own and operate making them barriers to wide-use adoption.

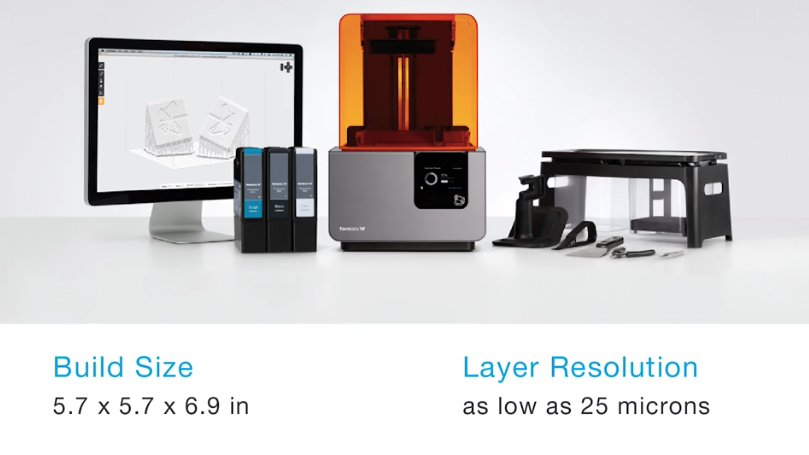

In 2011, Formlabs introduced industrial quality SLA to the desktop. With high-resolution, capabilities and materials previously limited to larger systems, Formlabs made SLA more affordable and accessible.

Starting at $3,499 the Form2 is the third-generation 3D printer from Formlabs. It has a considerable build volume for its size with a layer resolution as low as 25 microns.

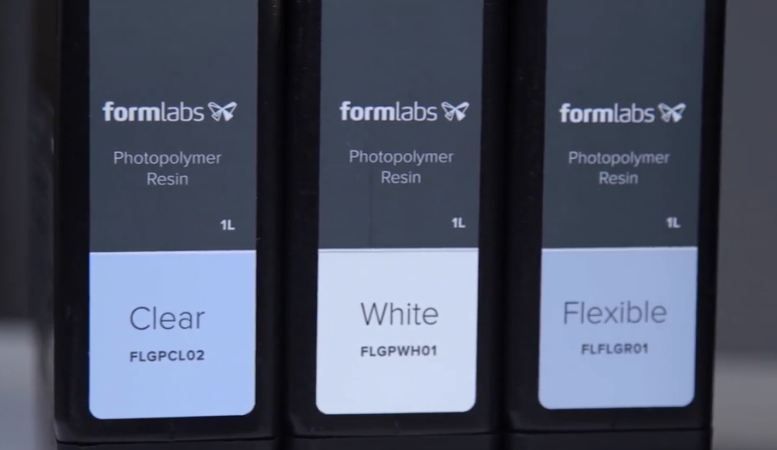

One of the most exciting things about the Form2 is the impressive materials library.

With a dozen materials and more to be released soon, availability includes:

Standard resins, like clear that are great for parts that require fine detail and surface finish for rapid prototyping and product development.

High-Performance Engineering resins, designed to simulate a wide range of end-use applications; such as: Tough, Flexible, High Temp and Durable; these are perfect for functional prototypes and manufacturing tools.

Resins for the dental and jewelry industries.

The Form2 enables you to print precise models with stunning surface finish – significantly smoother and more detailed than other plastic 3D printing technologies. Its low-entry cost makes it more accessible to engineering teams and companies looking to enter the world of additive design.

You can also add the newly released Form Wash and Form Cure to streamline and automate post-processing to consistently produce high-quality parts, with less time and effort.

For more information on the Formlabs Form2 3D printer, please click the button below.

Leave A Comment