It is critical educational institutions include technologies like metal 3D printing in curricula to give them hands-on experience with disruptive technology and avoid leaving students at a disadvantage as they enter the workforce.

Metal additive manufacturing, also known as 3D printing, is revolutionizing industries by enabling the creation of complex parts with intricate geometries that were once impossible to produce using traditional methods. Creating components by building up metal layer-by-layer has numerous applications and advantages, particularly for universities.

In addition to ensuring students have experience with digital tools like CAD, FEA, and generative design, investing in metal additive manufacturing allows students the opportunity to gain invaluable hands-on experience directly producing the parts they design. Having a 3D printer on campus also attracts researchers with the opportunity to conduct customized experiments, test new materials, and continue to push the boundaries of the technology for advanced industry applications.

As metal 3D printing continues to emerge as a key manufacturing technology, it is critical educational institutions include it in their curricula to inspire the next-generation of professionals and avoid leaving students at a disadvantage as they enter the workforce. Here are five reasons the Desktop Metal Studio System is a worthy investment for every educational institution.

1. Industry 4.0 Hands-On

The fourth industrial revolution converges digital and physical technologies for the next phase of advanced manufacturing. Developing curriculum and research aligned with the vision of Industry 4.0 is essential to maintaining a competitive advantage at attracting students and researchers alike.

Design for Additive Manufacturing is a growing field, actively supported by many CAD vendors. Practical experience is one of the best teaching methods, and the Studio System provides an approachable opportunity to gain a direct understanding of both design and manufacturing concepts, as well as implications for innovation, product development, and supply chains.

2. Across-the-Board Investment

Metal 3D printing is disruptive across a broad range of industries. From automotive and heavy industry to consumer goods and machine design, additively building complex metal shapes with Bound Metal Deposition touches almost every industry that students may enter as future professionals.

Existing university customers praise the Desktop Metal Studio System for its wide applicability, being used in different ways by various departments by a variety of students and across many types of lectures – from undergraduate classes to master studies and research projects.

Offering hands-on experience with this game-changing technology that easily creates dense, strong, metal parts relevant to a wide range of disciples and subject areas within the university environment is an all-inclusive investment.

3. Jumpstarting Student Teams

From race teams to robotics competitions, on-campus metal 3D printing allows student teams to turn their innovations into a competitive advantage.

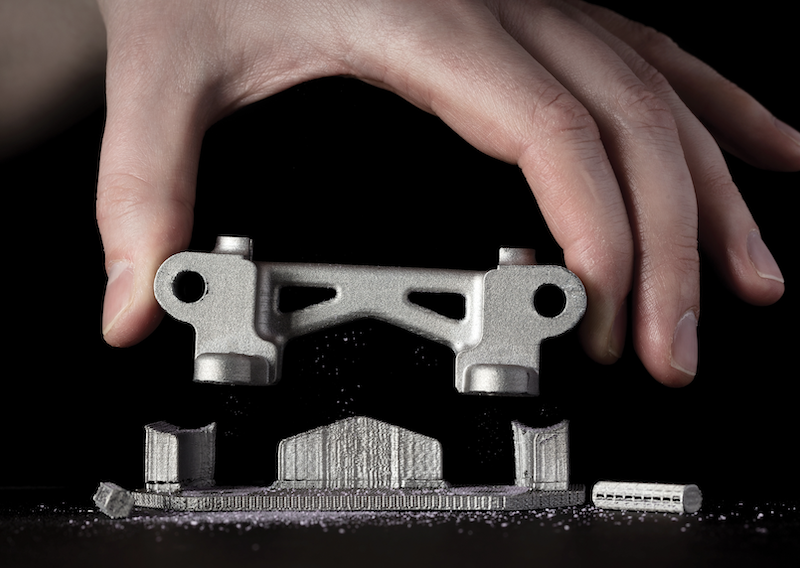

The design freedom of 3D printing allows students to unleash their creativity to develop solutions for challenges of lightweighting, performance efficiency, and cost-effective production. From complex channel designs that more effectively draw exhaust from a turbocharged engine to quickly iterated brackets that provide optimized support in an intense BattleBot environment, the Desktop Metal Studio System is an important tool in the success of a variety of student teams around the world.

4. Incubating the Business Community

Institutions of higher education serve as reference points to incubate disruptive technologies and implement road-to-adoption strategies for the local business community. Developing metal 3D printing expertise allows knowledge transfer to foster innovation partnerships and provide opportunities for the businesses in your area to benefit, especially small and medium-sized enterprises (SMEs).

5. The Easiest Way to Get Started

Designed as a plug-and-play system to be used in any classroom, workshop, or lab environment without strenuous safety or environmental restrictions., the Desktop Metal Studio System is the easiest way to get started 3D printing metal parts. The two-step Bound Metal Deposition process creates metal parts with no loose metal powders, no lasers, and no solvents for most materials.

The software-controlled process offers an easy-to-adopt approach, allowing the machine to be operated like a tool without hours of training or adjustments needed. Design files are uploaded into Desktop Metal software for auto orientation, support generation, and printing parameter assignment. After sintering in the Desktop Metal furnace, prints are removed from any supports via a ceramic interface layer that breaks away, leaving a dense metal part produced without the lead time or investment of traditional tooling.

For more information on Desktop Metal, please click below.

Leave A Comment