Formlabs New General Purpose 3D Printing Resins

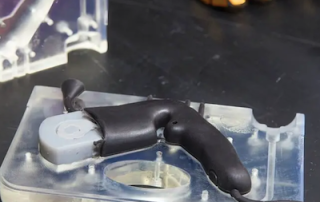

Formlabs’ New General Purpose Resins Make 3D Prints Faster, Stronger, and More Affordable Since Formlabs’ Grey Resin was announced in 2011 and shipped with the first iteration of Form 1, Formlabs customers have relied on General Purpose Resins for the majority of their printing. Over a decade and 400 million parts later, that still holds true; Formlabs General Purpose Resins are the backbone of workflows, from prototyping to production. The release of Form 4 opened [...]