Exploring the New Formlabs Elastic Resin

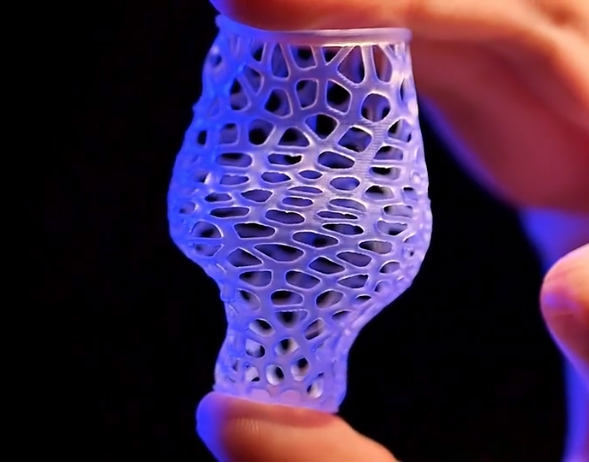

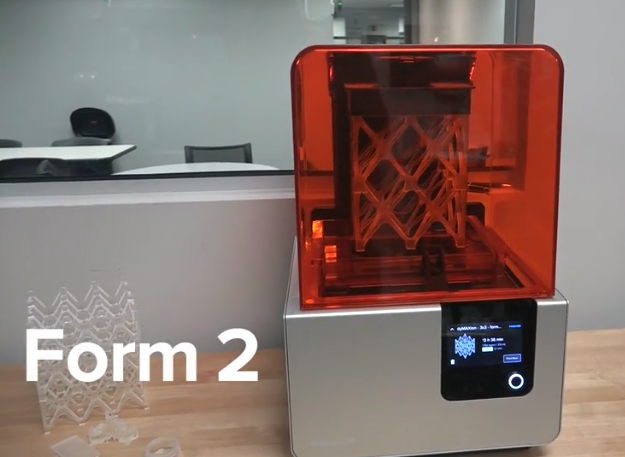

Formlabs recently announced their latest material – Elastic Resin and this article will take a closer look at it. Soft silicone and urethane parts are typically produced through moldmaking. These materials must be both highly elastic and strong. 3D printing them was once only possible on expensive industrial machine, but with Elastic Resin, companies can now simulate molded silicone, making it possible to print soft, resilient prototypes right on the desktop. Elastic resin is Formlabs' [...]