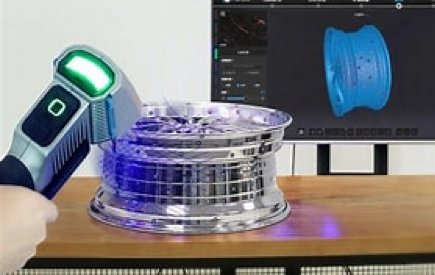

Hybrid 3D Scanner – LED Light and Laser

https://cimquesttv.wistia.com/medias/3ezitq93nc?embedType=async&videoFoam=true&videoWidth=640 Hybrid 3D Scanner - LED Light and Laser The hybrid laser and LED light sources make EinScan HX compatible with a wider range of object sizes, meeting the multiple needs of users.