Today we will discuss soluble support material for 3D printers that are in the extrusion category. During the extrusion-based 3D printing process, parts that feature structural overhangs or internal cavities require support material during a build. Think of it as temporary scaffolding extruded alongside the base material to support the part as it is building up layer by layer. Upon completion of a print, the support structure can be either torn away manually or dissolved in a solution.

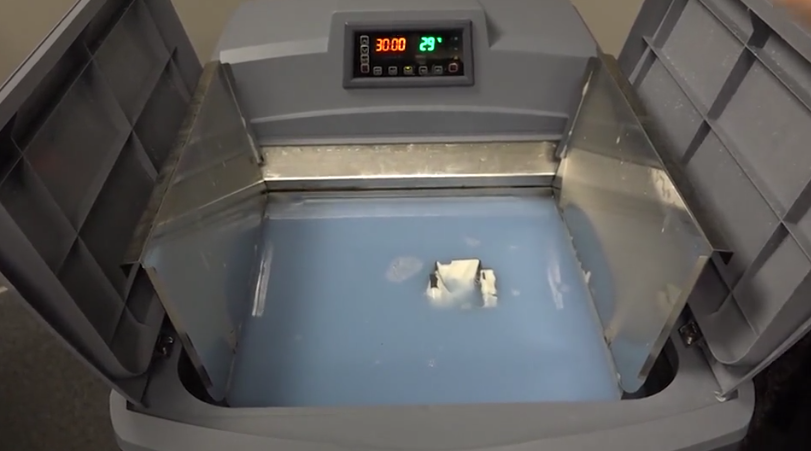

Soluble support is removed by a completely automated process using either a wash tank or a container filled with water.

Dissolvable material allows for geometries that have internal void and leaves little to no blemishes to the outer wall – keeping fine delicate features fully intact. Internal cavities and un-scarred surface-finish are features that breakaway support material cannot accommodate.

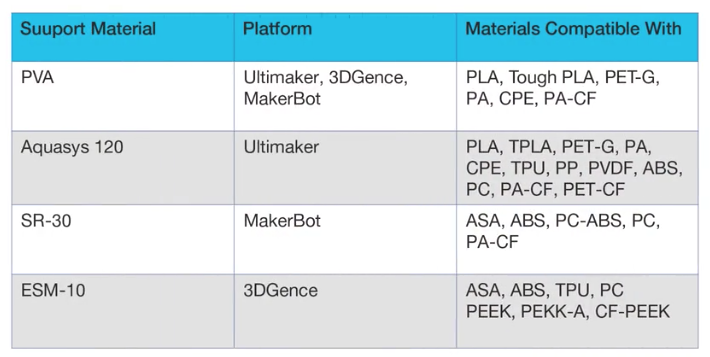

Let’s take a look at four different types of soluble supports material.

The first type of soluble support we’ll cover is the most common – PVA or Polyvinyl Alcohol, a water-soluble polymer. PVA is a colorless, odorless synthetic polymer with significant biocompatibility properties. It is compatible with PLA, Tough PLA, PET-G, and Nylon.

Aquasys(r) 120 is the world’s first tap water-soluble support material that works with a wide variety of engineering materials – it is stable in up to 120 °C build chamber temperature. AquaSys are compatible with all the materials that work with PVA + ABS, ASA, TPU, Polypropylene and Polycarbonate filaments.

Both PVA and Aquasys(r) 120 will dissolve in a simple container filled with water and by adding agitation, dissolutions times are significantly decreased.

Developed by Stratasys, SR-30 is a proprietary soluble support material that works seamlessly with PC-ABS, Nylon Carbon Fiber and other high temp materials, yielding exceptional results.

ESM-10 is a proprietary soluble support material engineered by 3DGence. It is the first of its kind to be compatible with performance materials – PEEK and PEKK-A, each of which have only had breakaway options outside of ESM-10.

Both SR-30 and ESM-10 require an ultrasonic tank that reaches at least 70 degrees Celsius with either Ecoworks or Techniprint’s sodium hydroxide concentrate for dissolution.

As you can see, understanding soluble support material is a key component to evaluate. Contact us below to discuss your application to see if dual extrusion 3D printing with soluble support material is the right fit.

Leave A Comment