Let’s take a look at the new Formlabs Nylon 12 Glass Filled powder 3D printing material. As applications for 3D printing continue to evolve, engineers are requiring a wide palette of materials to meet their needs. And with new gaps in supply chains appearing every day, there’s an increasing demand for functional in-house production. Formlabs Nylon 12 Glass Filled on the Fuse 1 can help make in-house production a reality. Here are some of the key characteristics.

Nylon 12 GF has a high stiffness and thermal stability. This is great for companies in automotive, aerospace, and product development, either for functional prototyping or small batch production.

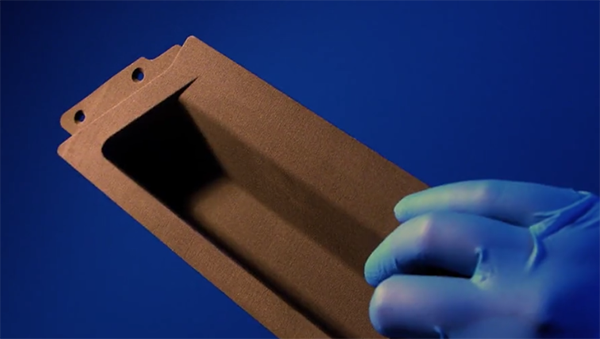

This material also has high dimensional accuracy and low warpage. The dimensional accuracy stays consistent at elevated temperatures, making it perfect for testing under harsher environments.

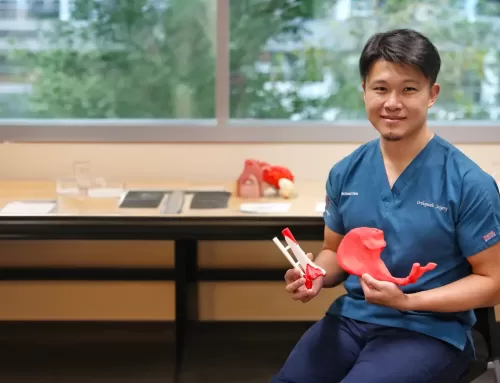

Medical manufacturers can also benefit from Nylon 12 GF. Medical devices, brackets, and enclosures are all ideal applications. Replacement parts for machinery are another great use that virtually any industry can benefit from.

As you can see, Nylon 12 GF enables manufacturers to take control over their means of production. Ideal for parts that require high rigidity and thermal stability, companies can create industrial-grade parts in-house, instead of relying on outsourcing and raw materials being in ready supply.

For more information on Formlabs 3D printers, please click below.

Leave A Comment