CHALLENGE

HARBEC utilizes robots to perform some of the tasks which are part of the daily manufacturing processes at the facility. A robot requires fitted tools to complete the duty for which it is called upon. These tools are called end of arm tools, which in many cases are multiple pneumatically actioned claws or grippers, attached to a bracket of the required shape. HARBEC owns many different 3D printing technologies which would be useful in creating the brackets for each job. Initially, a SLA printer was used to create the bracket. This bracket had decent mechanical properties, and worked well for the job at hand. Interest was shown to reduce the weight of the gripper brackets that are to be utilized by the robots. Using SOLIDWORKS topology optimization technologies, a new design was created which reduced the weight as much as possible, considering the required preserved areas and the forces on the design during operation. This optimized part was grown in the SLA printer, and the resulting component wasn’t as rigid as what was hoped for. A solution was sought after to maintain the lightweight design, but to ensure a component with similar stiffness to that of the initial part.

SOLUTION

Trials with the SLA printer weren’t successful, and alternate methods were analyzed to provide a solution. The other types of printing options available at HARBEC include FDM, Polyjet, and SLS. A part which is lightweight, stiff, and dimensionally accurate is desired for these end of arm tools. Knowing this, a decision to use the XYZ printing MfgPro230 selective laser sintering machine was made. A nylon material can be used in the machine, and this material was chosen to grow the end of arm tool. The resulting mechanical properties were exactly what was desired. After short inspection of the newly created part, it is easily noted that the part lost a significant amount of weight, while keeping a stiffness consistent with the original, non-optimized part.

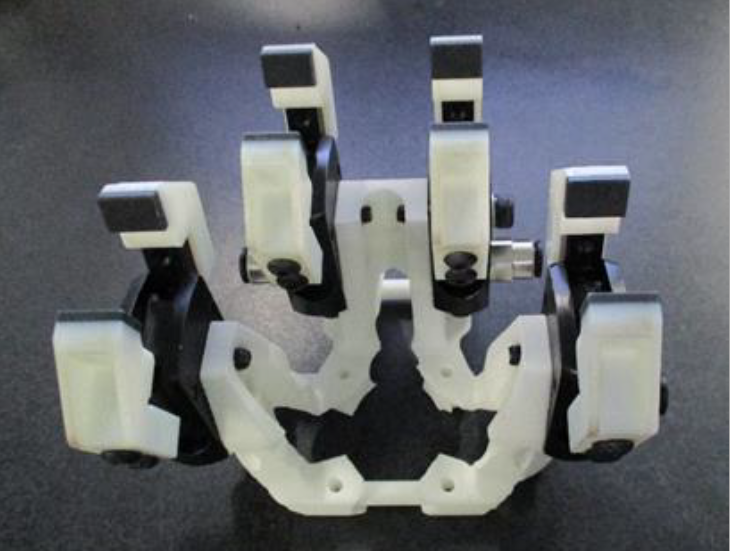

It is notable that the PA 12 material has larger values for many important mechanical properties, which may have a relationship with the increased rigidity when using the polyamide material in the MfgPro230. The PA 12 material has the properties that were desired for this project, and the XYZ Printing MfgPro230 used this material well, all while maintaining the directional accuracy required in this case. As a result, we have designed a lightweight, rigid, and accurate end of arm tool for the robot. The tool, fitted with the gripper mechanisms is imaged below.

RESULTS

The XYZ Printing’s MfgPro230 has the capabilities to create any of the plastic end of arm tools to operate the robots at HARBEC. Not only is the machine capable of these designs, it meets expectations for dimensional accuracy, as well as providing exceptional material properties, which allow for the optimization of the tool designs that are to be used. HARBEC is looking forward to exploring the additional opportunities for manufacturing improvement given by the usage of the XYZ Printing MfgPro230.

To view this entire case study, please click the button below.

Leave A Comment