METAL AND PLASTIC

3D Printing is changing the way products are designed, developed, tested, and manufactured.

From entry-level 3D printers to industrial systems, we have the tech to help you produce conceptual & functional prototypes, end-use parts, models, manufacturing tooling, jigs & fixtures, and more.

CUSTOM SERVICES

We are very focused on our customers because we know that our success depends on your success.

We have made it our mission to ensure that you not only get the right product for your needs but also that months and years into the ownership, you continue to be successful with it. We offer:

- 3D Printing

- 3D Scanning

- Reverse Engineering

- Design

- Custom Post Processors

THE PRODUCTS WE REPRESENT

We offer a wide range of products and services in the design and manufacturing industry. No matter what your manufacturing challenge is, we are here to provide you with the best solution.

IN-PERSON & REMOTE TRAINING

In-person Mastercam & Geomagic Classes

Our classrooms generally hold a maximum of 8 students. We strongly believe that our small class sizes are essential to ensure maximum instructor/student interaction and greater student success. Each student works on his/her own computer, and there is a great focus on hands-on learning. All software classes are taught on the latest version.

Remote Mastercam Classes

Years before the virus situation changed our world we were doing remote virtual online training for customers. This remote option saved time driving and money on travel costs. We have invested in new technology and instructors to ensure a learning experience as if the instructor were there looking over your shoulder guiding you.

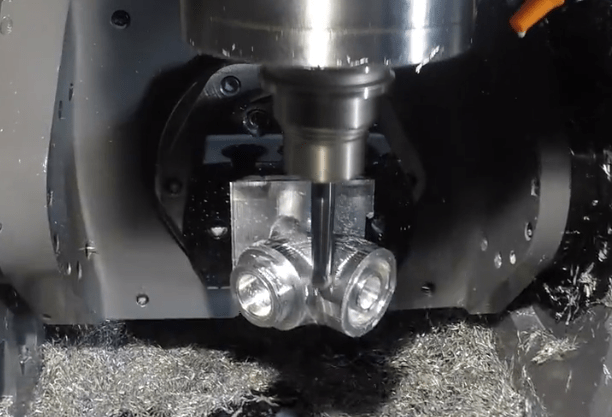

Applications Training

Our High-Efficiency Milling class is an intense course on how to implement, evaluate and select components for high-efficiency milling to get shorter cycle times, reduce tool wear, and extend machine life. Students will learn guidelines for selecting key components with hands-on interactions to build their ability in identifying and creating an efficient milling process.

OUR LATEST 2 MINUTE TUESDAY VIDEOS

Two Minute Tuesday is a popular video series from Cimquest TV. These weekly videos focus on various topics in the manufacturing industry. Every Tuesday you’ll find a new, informative video from the Cimquest Team covering Mastercam, a variety of 3D Printers, CAD, Reverse Engineering & Inspection solutions, as well as Customer Spotlights, Tips & Tricks, What’s New, and much more. Sign up today so you don’t miss out.

Sign up for 2 Minute Tuesday's |

THE LATEST ARTICLES FROM THE BLOG

We post three new articles every week that covers the latest Cimquest, Mastercam, and 3D Printing happenings, product offerings, and update info along with general Industry trends and breaking news.

Join Us for a Nexa3D Live Demonstration

This month we will be hosting two live demo events to showcase the Nexa3D ultra-fast 3D Printers. These events will be taking place . . . February 20th in Branchburg, New Jersey February 25th in Sterling, MA During these live presentations, we will be taking a deep dive into the [...]

Cimquest and Nexa3D Announce Partnership

Cimquest, Inc and Nexa3D Announce Partnership to Enter the Eastern US 3D Printing Market Cimquest, a leading provider of 3D printers, and manufacturing and design products today, announced a partnership with Nexa3D, the maker of ultrafast stereolithography production 3D printers. After an extensive vetting process, this new agreement fills a [...]

3D Printing for Auto Racing Industry

In Motorsports, engineering teams are always under the gun to improve designs and enhance racing performance. To win races consistently teams must find innovative ways to reduce weight while maintaining the strength necessary to withstand extreme conditions. These conditions include high temperatures, along with the harshness and vibration that come [...]

Welcome Our Latest New Employees

We are continuing to grow our Cimquest team and have hired quite a few new employees. Please help us to welcome the following new hires. Jim Harrison has worked as an Additive Manufacturing (AM) engineer for 30+ years, in aerospace, medical device and consumer products. He started his career [...]

HEAR IT FROM OUR CUSTOMERS