Metrology Minute – How do I choose the first scanner for my company? – Part 2

After considering part size and perhaps cost, you’ve narrowed down the field somewhat. The next thing to consider is the application itself. Setting novelty uses aside, the five most common uses for scanning are:

- Metrology

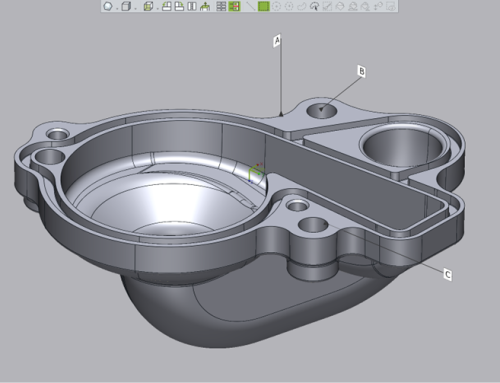

- Reverse Engineering

- 3D Printing

- Asset creation for a Web Page

- Virtual Reality / Augmented Reality or video game assets

Metrology

Reverse Engineering

3D Printing

Web Content

Virtual Reality or video game assets

Since most Cimquest customers are more heavily involved with the first three, that’s where we’ll focus our discussions.

Accuracy is particularly important, especially when it comes to metrology. To ensure appropriate accuracy for metrology, reverse engineering, or 3D Printing you will want to ensure the scanner manufacturer publishes its accuracy. In fact, for metrology, the accuracy of the scanner should really surpass your most stringent accuracy requirements by 10x. For example, for part accuracy manufactured requirements of +/-.010” your scanner’s accuracy should be able to achieve +/-.001”.

Next, consider the scanner’s resolution. Resolution is often confused with accuracy but it is actually very different. It is the scanner’s ability to capture fine detail. One can consider resolution as the density of a point cloud or, when it comes to a mesh file, it represents the shortest triangle length achievable by the scanner.

Many scanner manufacturers refer to resolution as ‘point spacing’ or ‘point density’ but again, be careful to not confuse point spacing, point density, or resolution with accuracy. Scanners can have a very high accuracy with poor resolution or vice-versa.

So, for metrology, reverse engineering, or 3D Printing, both accuracy and resolution must be considered, however when scanning for the creation of Web Assets, video games, or AR/VR technology color texture is likely the most important attribute the scanner needs as accuracy and resolution are far less important. In fact, for Web assets and video games lower resolution is preferred as that will make the asset a ‘lighter weight’ file (i.e. smaller and therefore easier to manipulate on the Web).

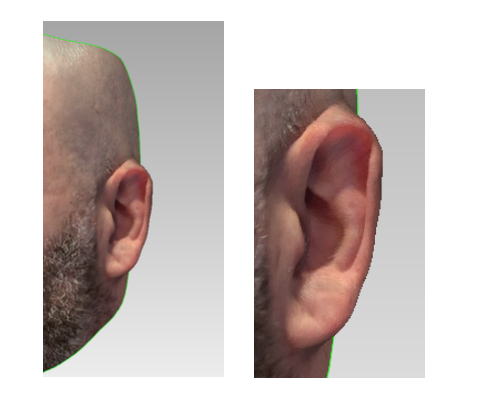

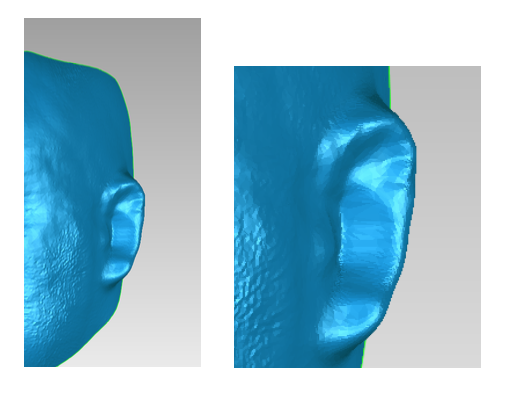

Color texture is the ability to wrap a color image of the part around the scan. Some scanners can capture color texture while others only capture shape. Very often, this color texture is used by scanner manufacturers to hide poor quality scan, i.e. – generally to hide poor resolution. So when evaluating a scanner that can produce color texture have the presenter ‘turn off’ the texture so you can see the underlying scan (point cloud or mesh). If the features of the part scan look pretty much the same as with the texture turned on or off, then the resolution is likely adequate to capture the detail for that particular part.

Here’s an example where this scanner manufacturer uses color texture to hide low resolution scans. When turning off the texture, it hardly looks like a human ear any more. All of the fine detail is lost.

Color texture turned on – Looks just like a human ear!

But look with the color texture turned off!

The ‘true shape’ of the scan is what is seen in blue, so if machined or 3D Printed for example, the blue shape is what would be made, not the image with texture, on the left.

We hope you enjoyed this month’s Metrology Minute. Please feel free to contact Joel with any comments or questions.

Joel Pollet (jpollet@cimquest-inc.com)

Leave A Comment