Welcome to Part 3 of our Metrology Minute series.

In parts one and two of this three-part series, we explained several key components in choosing your company’s first scanner; Field of View (FOV), Accuracy, and Resolution are the first considerations. For a quick review . . .

- Field-Of-View (FOV) is the volume envelope that your scanner can ‘see’. Ideally, the FOV is large enough to scan your largest parts yet still maintain the accuracy and resolution you require.

- Accuracy is the actual tolerance of the points acquired on the surface being scanned. So if a scanner’s accuracy is +/-.001”, then the data points collected from that scanner in a calibrated state are all within that tolerance.

- Resolution is a scanner’s ability to capture fine detail. Resolution is sometimes referred to as ‘Point Spacing’ and controls the tiniest features a scanner can capture. Sometimes it is easier to consider resolution as the density of the point cloud. For example, capturing a car door’s surface requires a far less dense point cloud than capturing the detail on a coin.

The next two considerations are Repeatability and Color/Texture.

Testing for repeatability is fairly straightforward. Ideally, multiple individuals can participate in the testing / resulting accuracy and everyone’s resolution results in scans that are within an acceptable deviation from each other’s results.

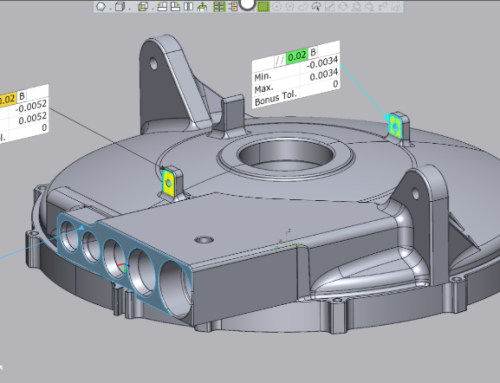

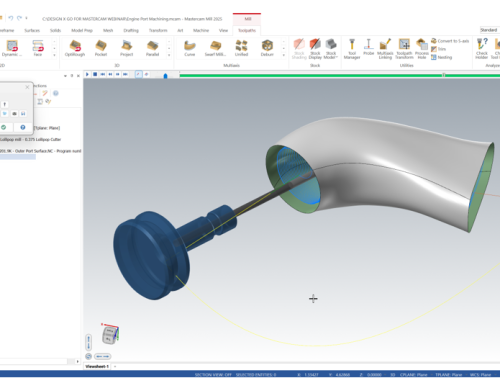

Some type of metrology software needs to be deployed in order to check the scanner’s accuracy and resolution against either a nominal CAD model or against each other. For any testing we do at Cimquest to validate scanners for resale, we use Control X metrology software. If a CAD model is available, we’ll utilize it as representing the nominal (perfect) shape. However, if no CAD model is available, we’ll typically take the very first scan and make it the benchmark.

Each participant in the study perhaps scans the same part 15 times, so if 3 individuals participate in the study, then 45 scans will be taken and compared to nominal for accuracy and resolution to see how repeatable the scanner is, regardless of who is doing the scanning or whether it is their first or last scan in the study.

Next, we must consider whether capturing color texture is important. As we discussed in Part 2 of this series, a scanner’s captured color texture is very often used to hide poor resolution scans. Almost like a JPEG wrapped around a scan to hide its underlying resolution. But what if the color texture is important? What if, for example, we need to scan products that are to be displayed in an online Web store?

In this case, capturing color texture may be far more critical than accuracy and resolution. In fact, the lower the resolution the better when it comes to Web performance. We often refer to these as ‘lightweight scans,’ meaning the accuracy and resolution are of little importance but the image itself and ability to manipulate (rotate, etc.) on the Web is of far greater importance.

So low resolution scans with high DPI images (also known as color maps) are the best combination of parameters for Web-based displays and usage.

This wraps up this 3-part series of ‘How to select my first scanner.’ Please feel free to contact Joel Pollet with any comments or questions by clicking the button below.

Leave A Comment