Let’s take a closer look at the HP 3D printing and their Multi Jet Fusion for machinery and production line components. Factories utilize machines of all shapes and sizes.

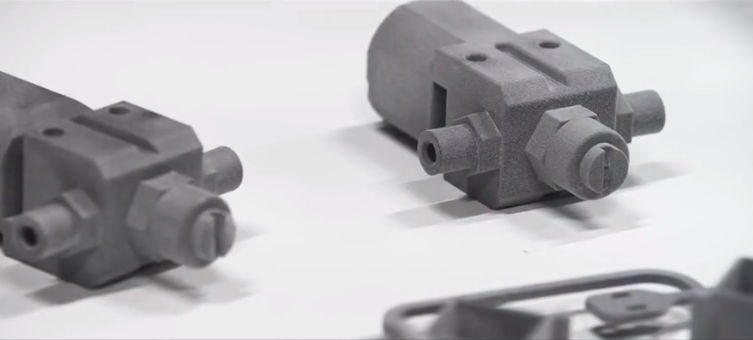

These machines are highly specialized and consist of custom components made in small volumes. As industries strive to add more value to their customers, manufacturers are under pressure to reduce costs associated with machinery.

HP Multi Jet Fusion offers a solution for producing optimized machine components, and at greater speeds and lower costs than conventional methods.

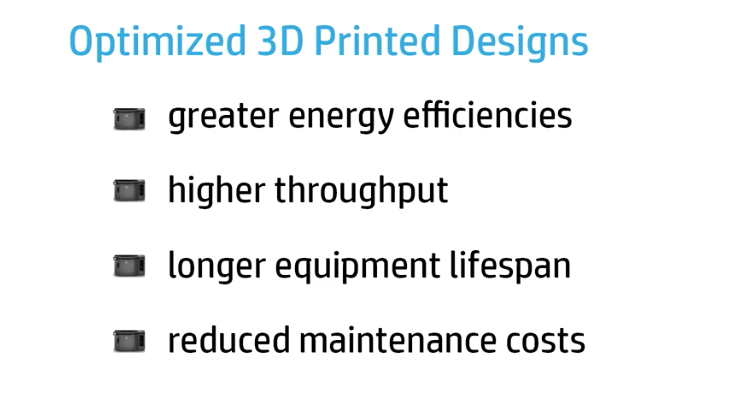

Through greater speed with HP’s platform, production line downtime is reduced. In-house, on-demand production of multiple designs in parallel can also increase production line flexibility.

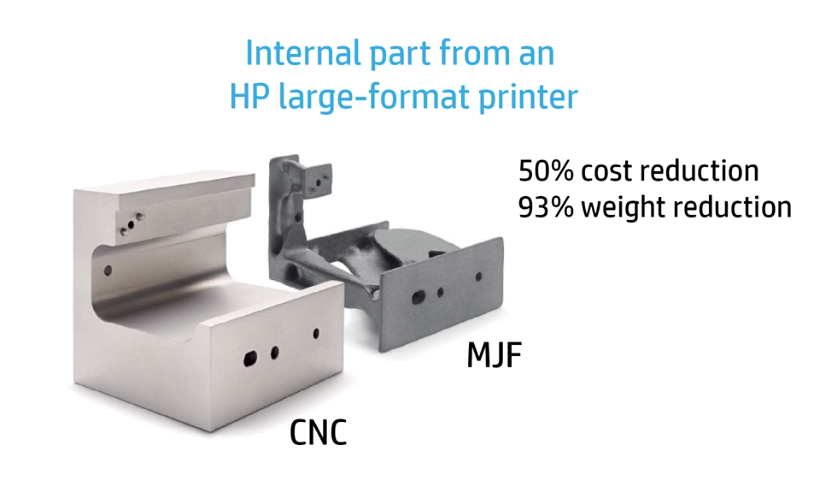

Complex geometries made possible through 3D printing will enable lighter parts with enhanced performance. This is thanks to lattice structures and generative design.

Moreover, HP plastic parts are lighter than aluminum or steel, providing a myriad of benefits. These unique, non-standard parts allow for customized setups adapted to each machine and floor plan dimension.

The benefits of speed and design freedom all affect the ultimate cost. 3D printing can help reduce inventory and transportation costs through just-in-time production. The reduction in material and minimized downtime of operations contribute greatly to these savings.

As you can see, HP Multi Jet Fusion can help drive greater production line efficiencies with lightweight, high-performance parts. By implementing these systems, companies can fabricate original and spare parts in-house, reducing lead times from weeks or days to a matter of hours.

Please be sure to sign up for our 2 Minute Tuesday video series to receive information like this in video form every week. More info at the button below.

Leave A Comment