This post is Part 3 of the topic: Leverage and import organic shapes into CAD and today we will introduce you to Generative Design.

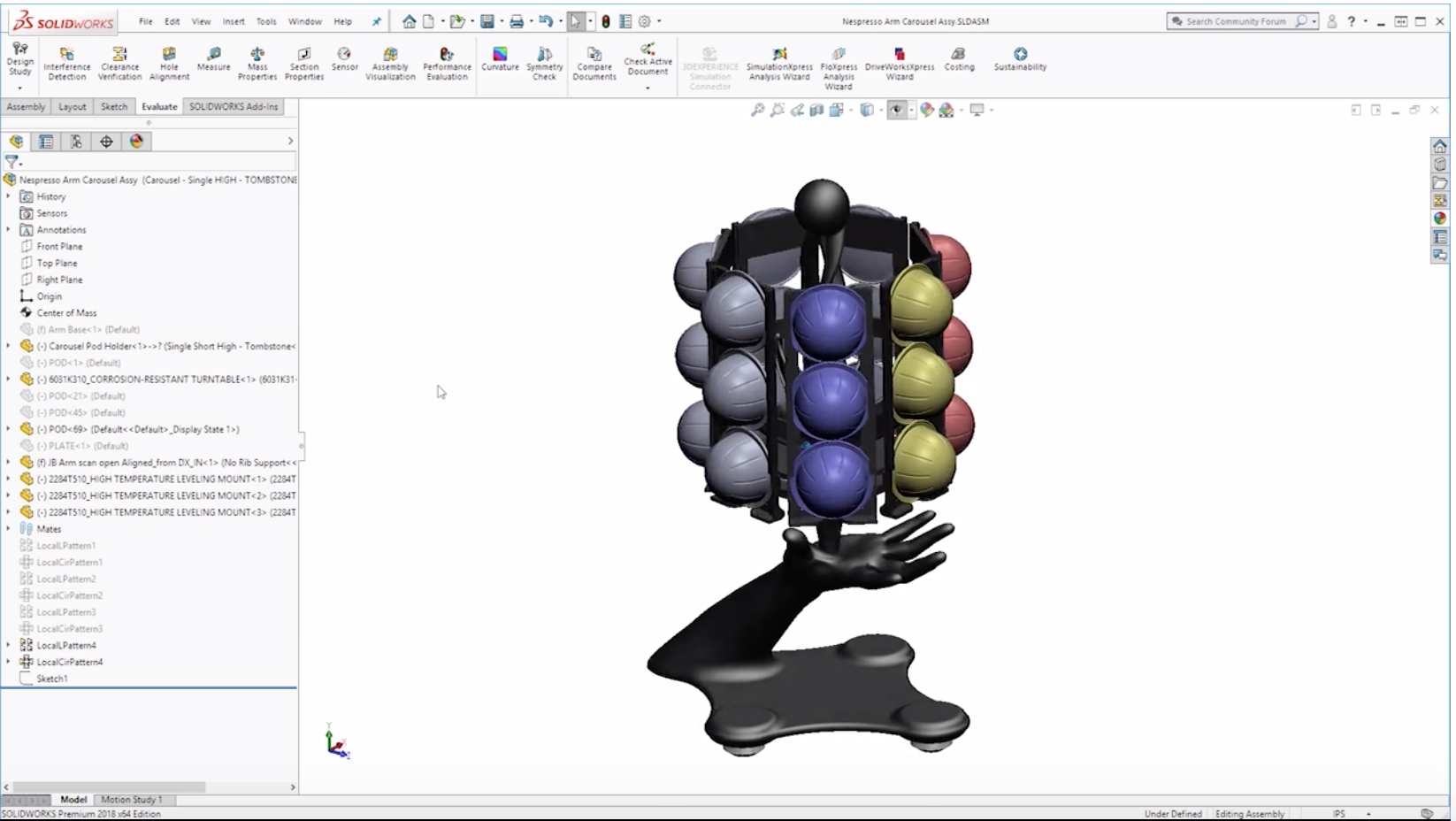

In previous posts, we briefly discussed the value of having the ability to capture organic shapes for use in CAD design. To illustrate this process, scanned our engineer’s hand and then integrated that scan into CAD in order to design a rotating Nespresso Pod holder.

Now, we will finalize the CAD design phase by using Fusion’s Generative Design, to assist us during the model creation process.

By now, the Nespresso pod holder is almost complete. The base integrates the hand and forearm and we have a carousel that sits and rotates on a turntable about the center of the palm. Now we need to determine how the turntable will connect to the pod holders.

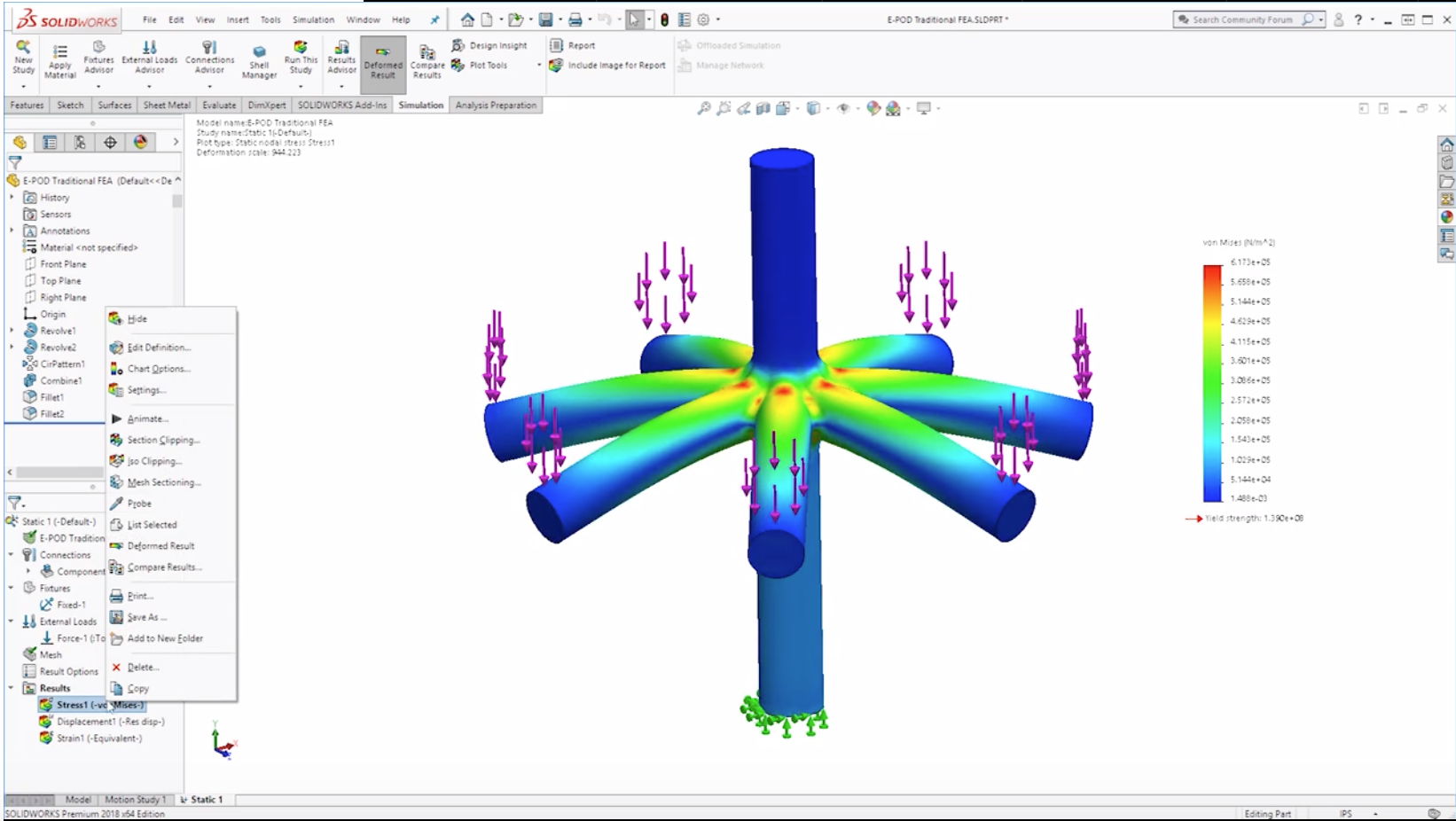

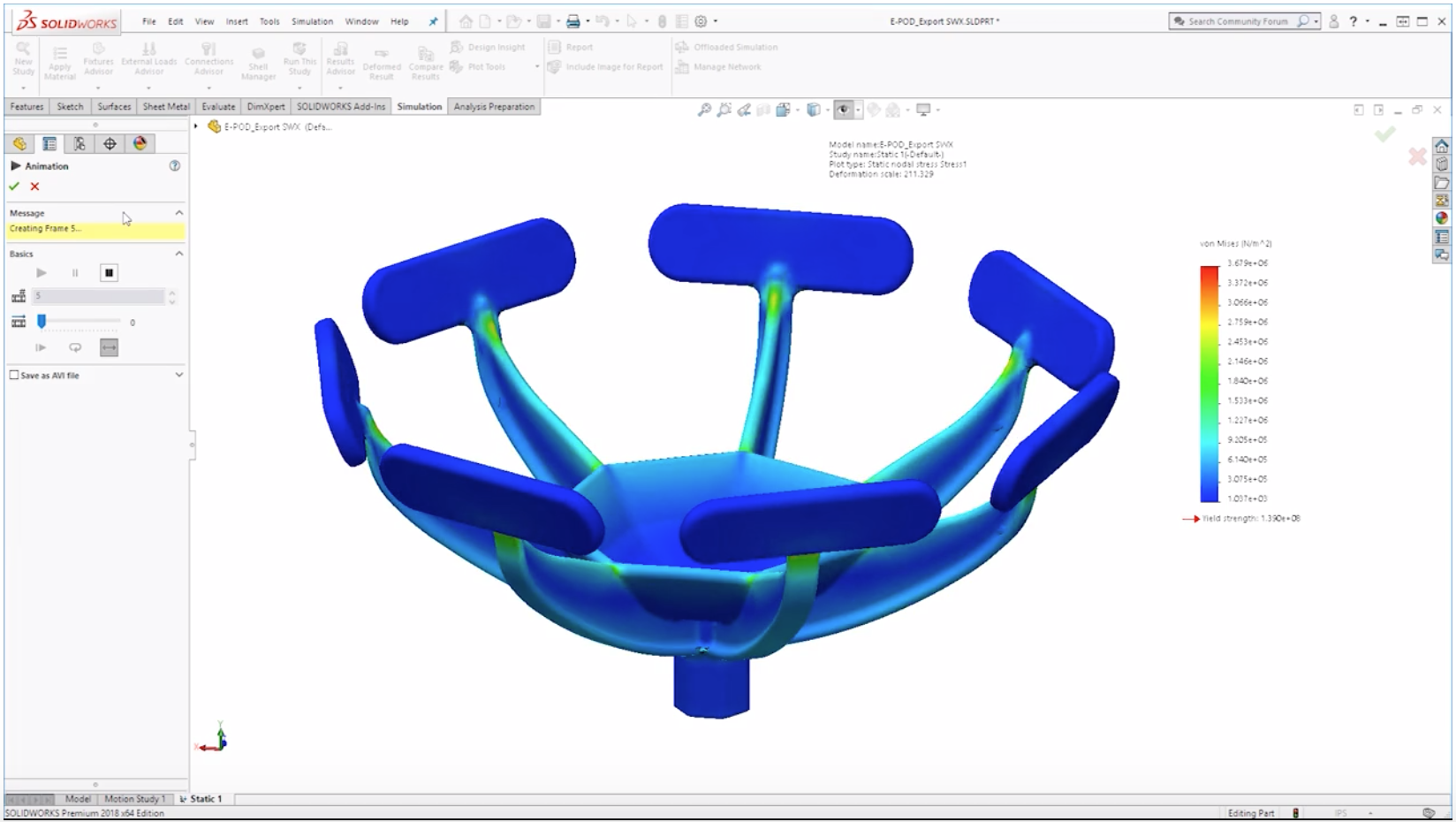

Traditionally, we would make our initial attempt and create a shape that we think would be structurally sound. We would then run that shape through FEA; make modifications, and repeat this cycle to ensure that we don’t over design the part.

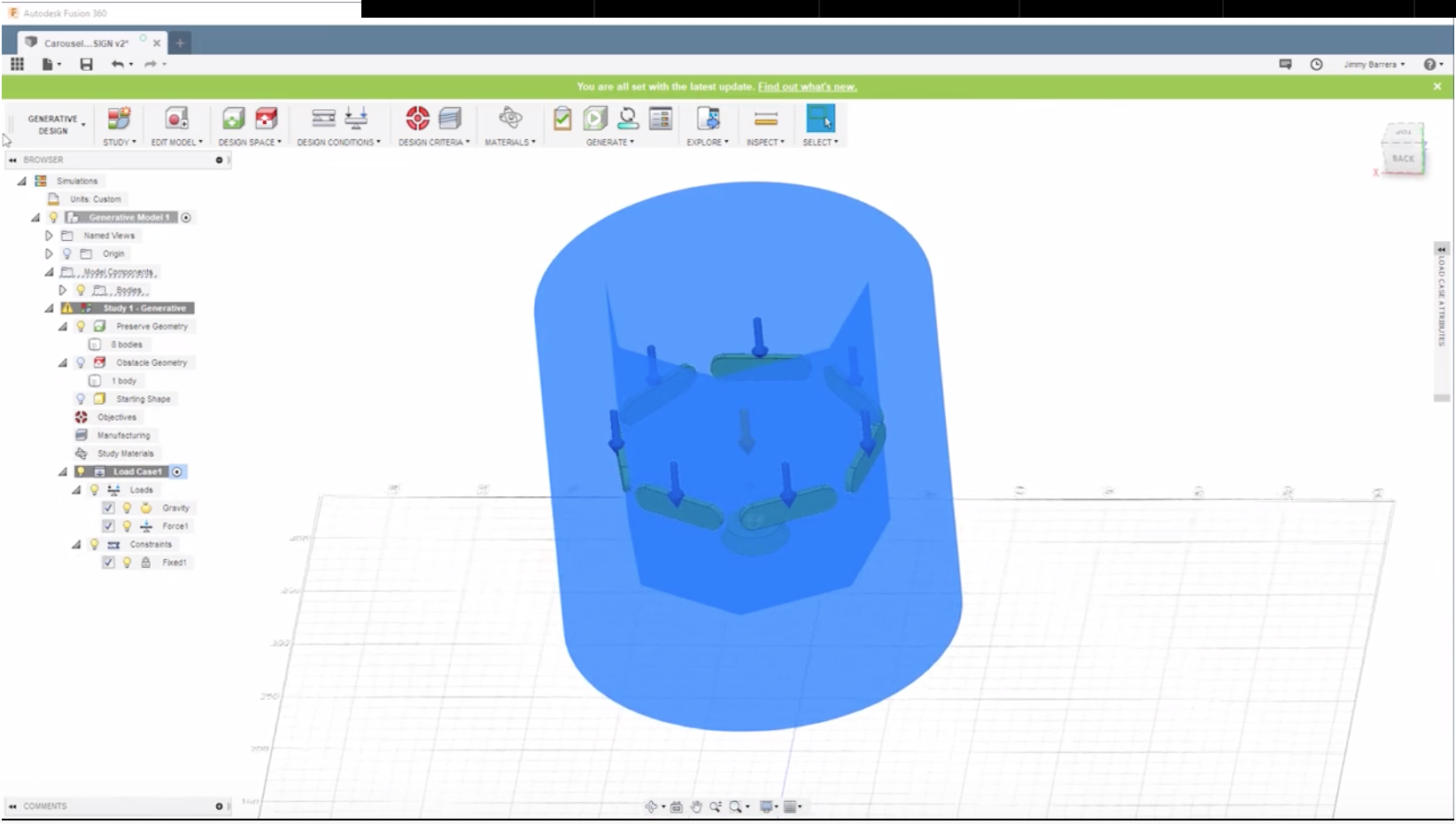

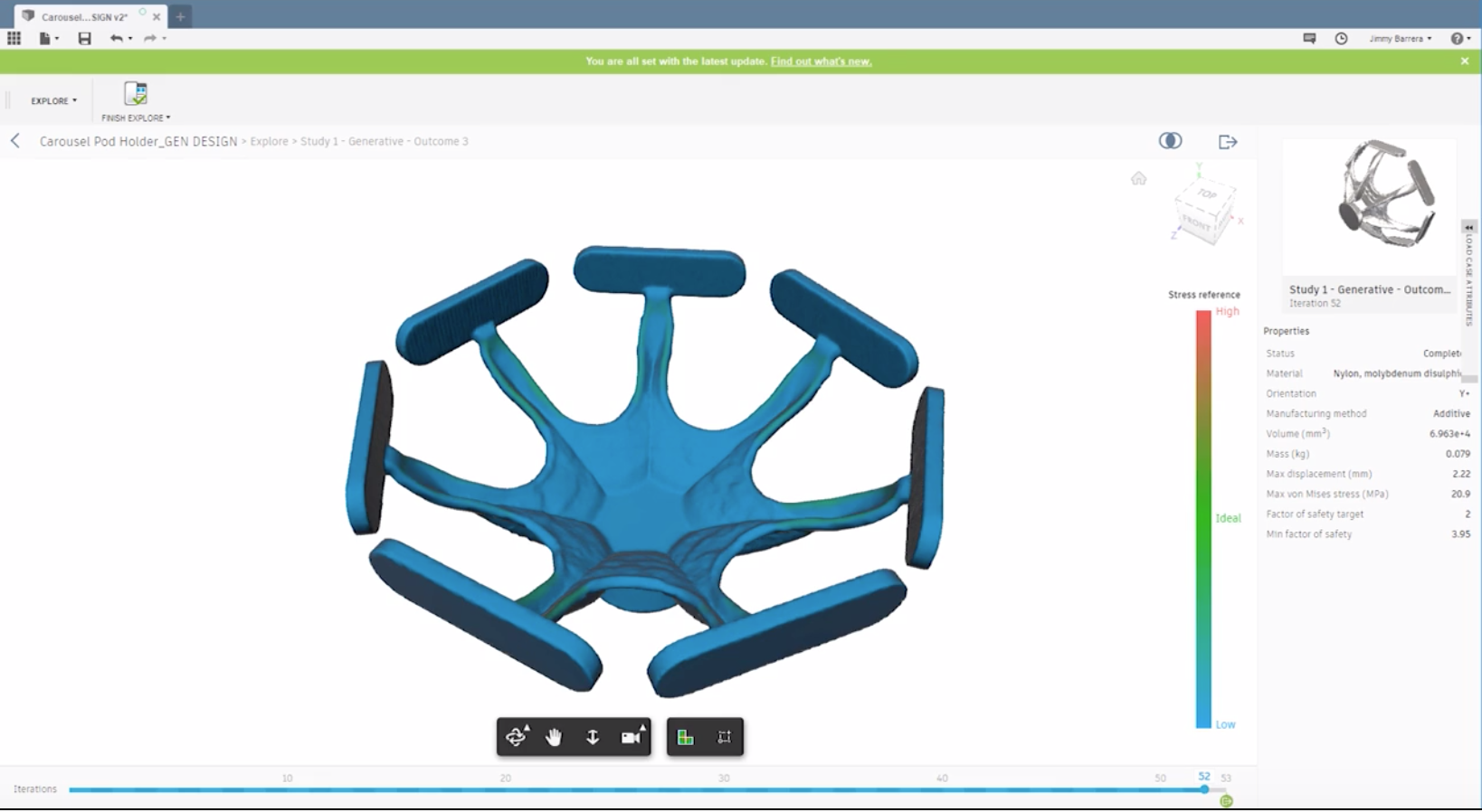

A short cut to this iterative cycle is to use Fusion’s Generative Design. In essence, the software generates a design or shape, based on the parameters that you set. For example, you assign which geometry needs to be preserved and which are the keep out areas in the final generated design.

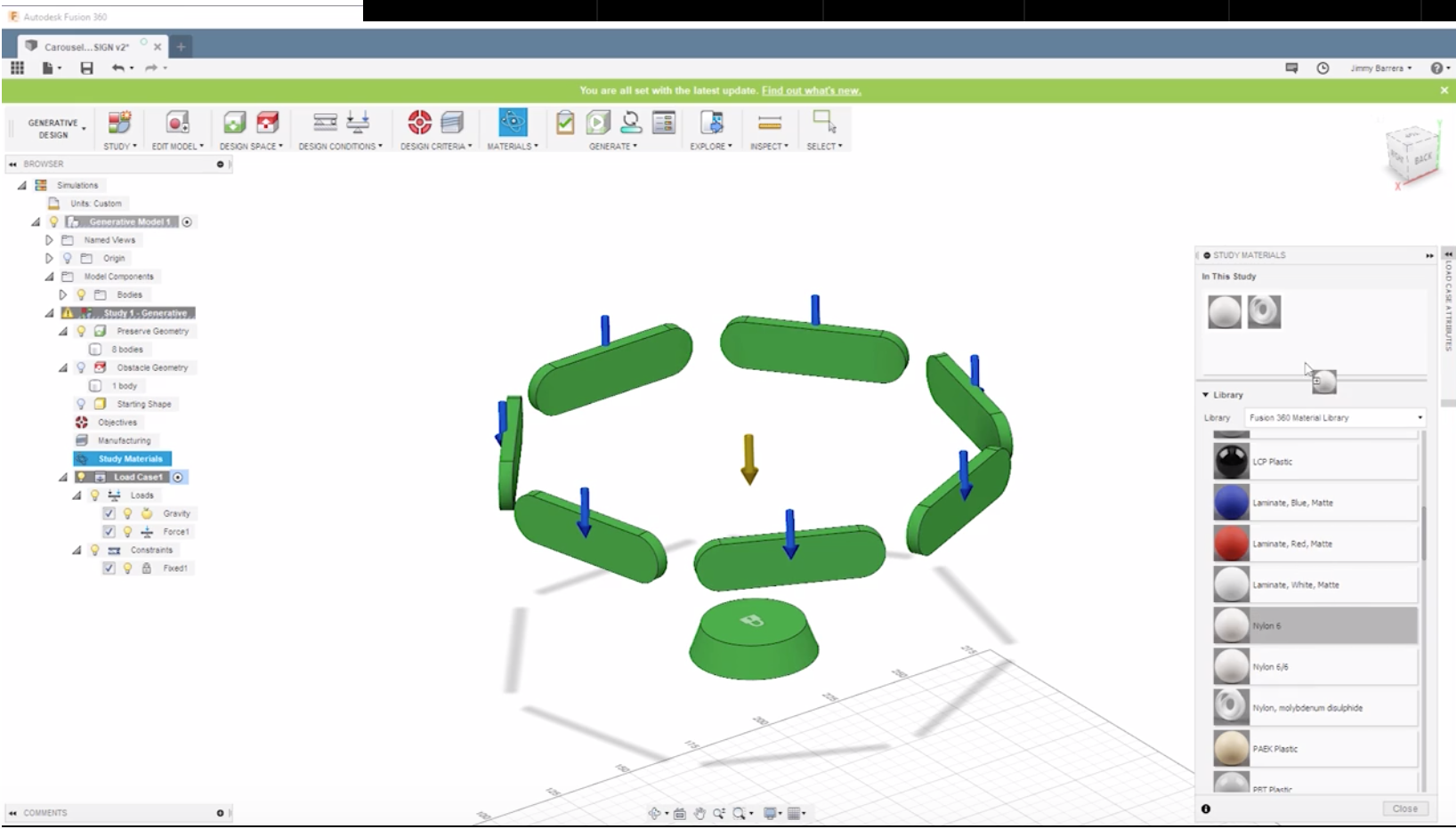

You also add constraints and loads, assign the materials that you are analyzing, and set your objectives for the study. In this case, our objective is to minimize mass and at the same time maintaining a FOS of 2.

The software then goes through different iterations using the study parameters you set, and at the end provides you with various options for you to choose from. Usually, the design that is generated is nothing like you would have ever imagined, but it does meet the design criteria!

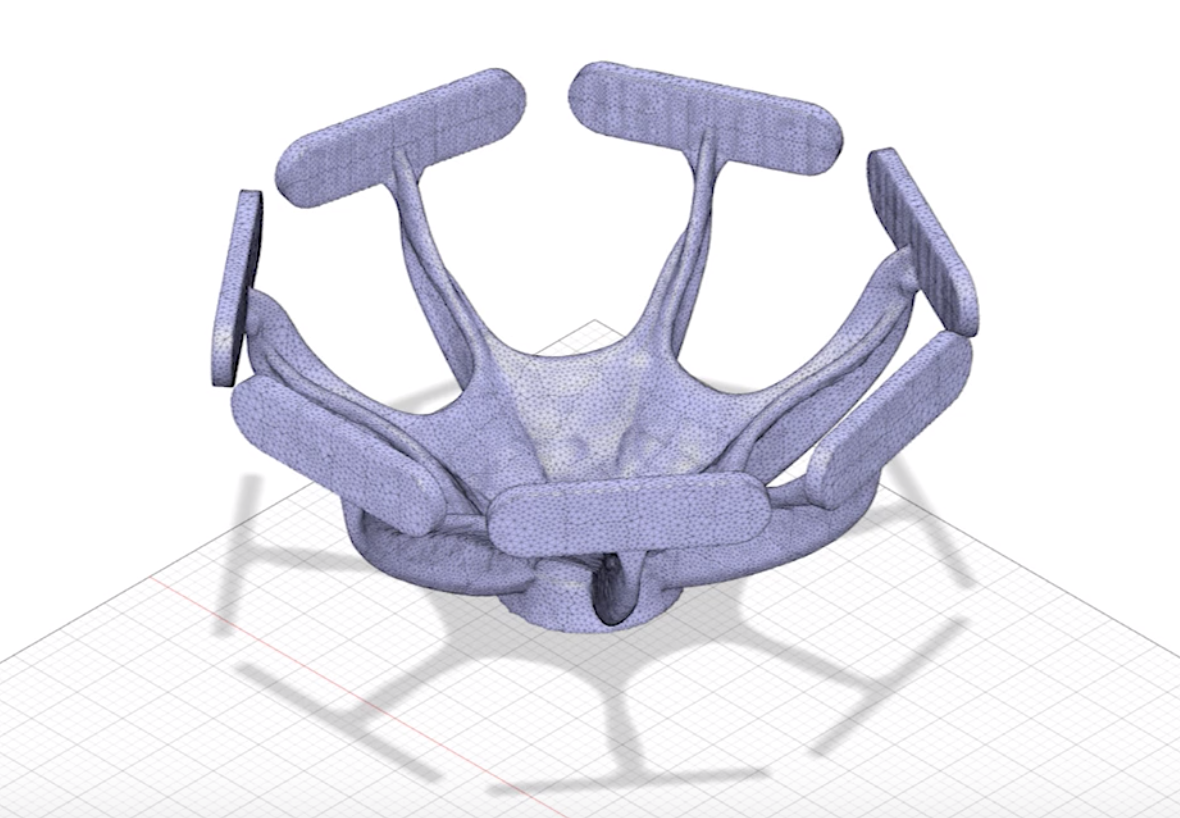

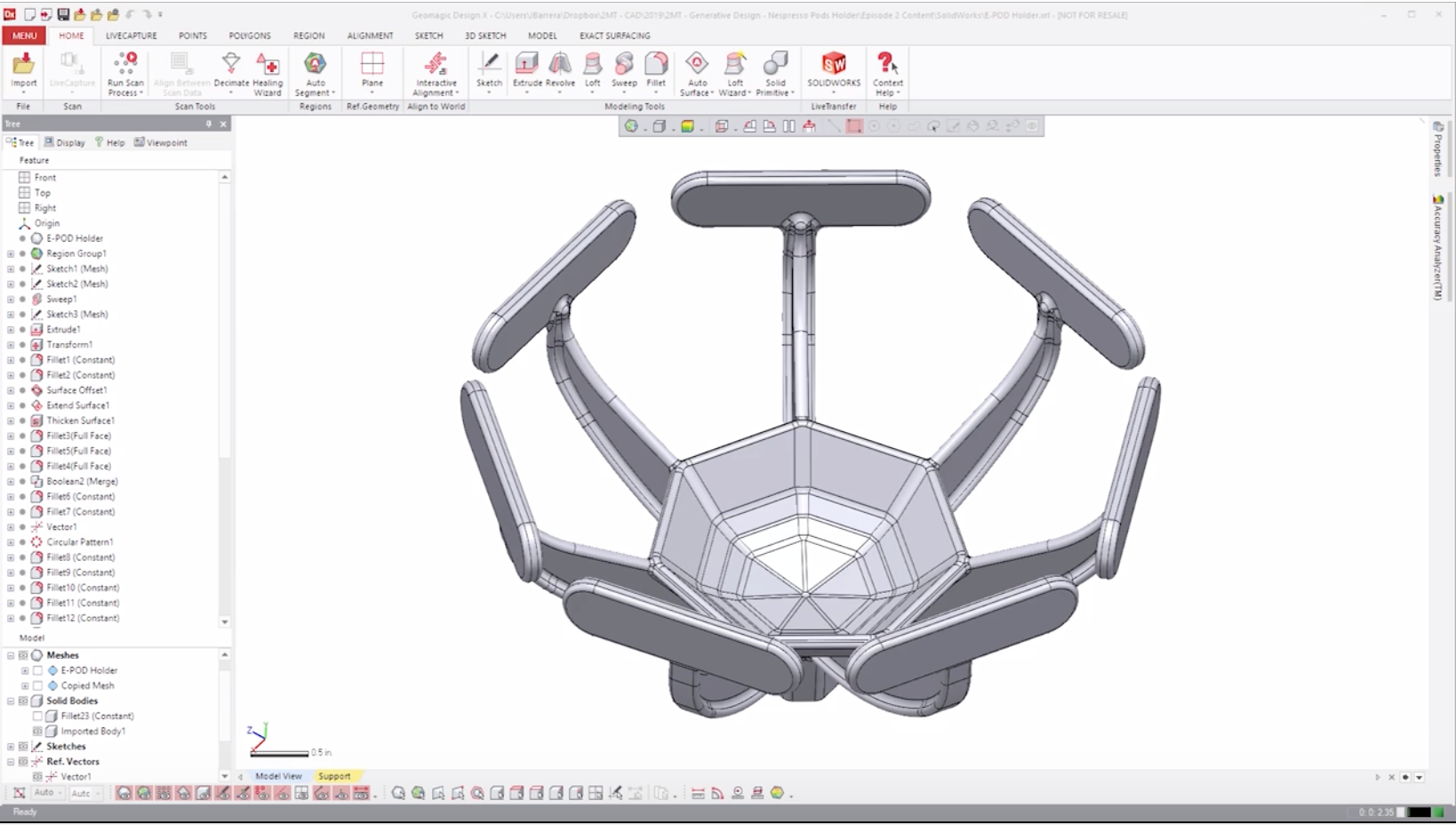

Since we were going for more of a mechanical look, we exported this shape as an STL into Design X and reverse engineered a mechanical part, over the organic part.

The results were amazing. The material distribution is optimal, it is structurally sound, mass has been minimized which will reduce material and costs, and we saved time because we didn’t have to go through the traditional FEA iterative process!

As you can see, Fusion’s Generative Design can be a great tool to use when you want to create an optimal design that meets engineering criteria, while getting it right the first time!

Please be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below.

Leave A Comment