Working more efficiently and effectively is a goal of essentially every organization, regardless of sector or industry. Using 3D printing, many companies around the world can increase productivity in warehouses, assembly lines, and factories, enabling them to achieve results otherwise impossible. Read on for real-world applications that companies are leveraging to increase their productivity.

Support Tools and Quick Fixes

In a fast-moving environment, time matters. Take Heineken’s bottling plant in Seville, Spain, for instance, which produces more than 500 million liters of beer each year. Efficiency is the name of the game, which means spare parts and other tools must be quickly available should the need arise. Using 3D printing, Heineken is able to print spare parts and tools on demand, minimizing downtime and ensuring that product is continuously manufactured.

Trivium, which manufactures tin packaging for products used in industries such as beauty and personal care, food and beverage, and pharmaceutical, uses a device that measures the speed of its conveyor belts. When the wheel of this device broke, however, the company was often left waiting on a replacement. By 3D printing the wheel, downtime was reduced from days – or even weeks – to hours.

Assembly Tools

Workers at both Ford’s Cologne and the Volkswagen Autoeuropa plant, use 3D printing to create tools, jigs, fixtures, and other manufacturing aids used daily on its assembly lines. These tools save the companies time and money. VW’s 3D printed wheel protection jig, for example, previously sourced for $967, but can now be printed at just $26.

This 3D printed wheel protection jig was previously sourced for $967, but can now be printed at just $26. Tool development time has shrunk from 56 to 10 days.

Ford, meanwhile, uses more than 50 custom-printed tools and parts to assemble the Ford Focus.

Quality Parts

3D printing isn’t just for prototypes. As the technology evolves, more and more companies are using it to create parts fit for hard work in a hard environment. Azoth is an Ann Arbor, Michigan-based company that focuses on combining traditional manufacturing quality with the efficiencies of rapid prototyping. Using 3D printing, it enables companies such as John Deere, GM, and Ford to create digital inventories of parts that can be printed whenever, wherever.

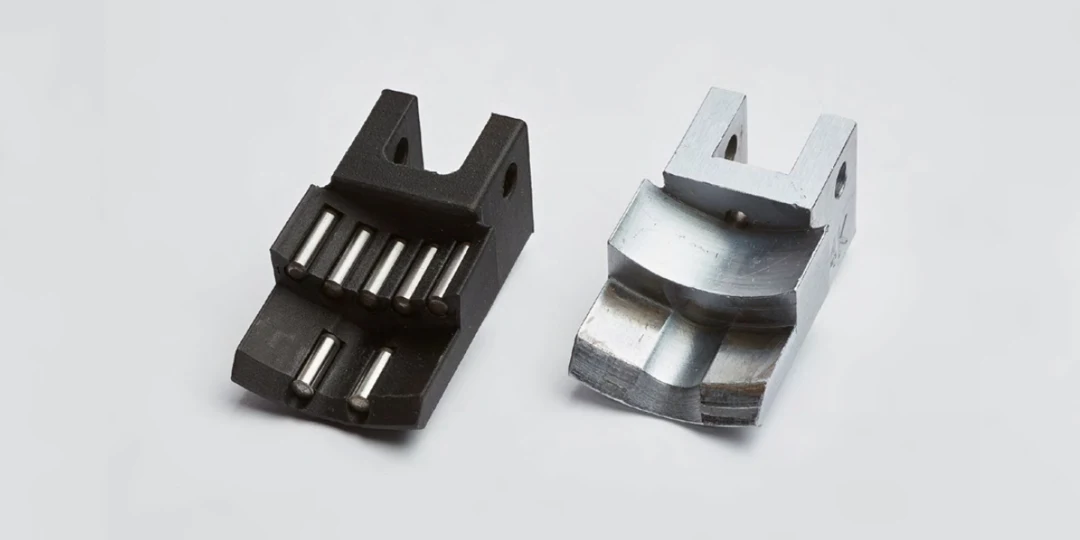

Take these aluminum gripper fingers, which were converted to polymer gripper fingers, and are able to be produced more quickly, at a fraction of the cost – with added, replaceable hardened dowel pins.

Created by Azoth, these aluminum gripper fingers were converted to polymer gripper fingers

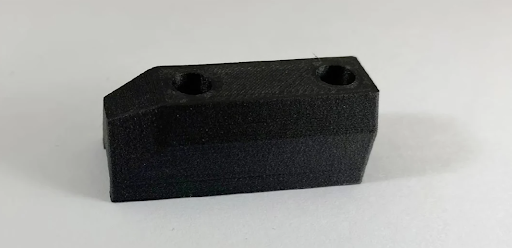

Or these stop blocks or wear pad parts, traditionally produced in nylon. When 3D printed, the parts outperformed the original component thanks to its fiber-based materials – and result in cost savings of nearly $30,000.

A stop block or wear pad part, created by Azoth

Transport Tools

Gerhard Schubert GmbH and Trivium are both using 3D printers to create parts or tools that improve the guidance of end-use parts within production lines.

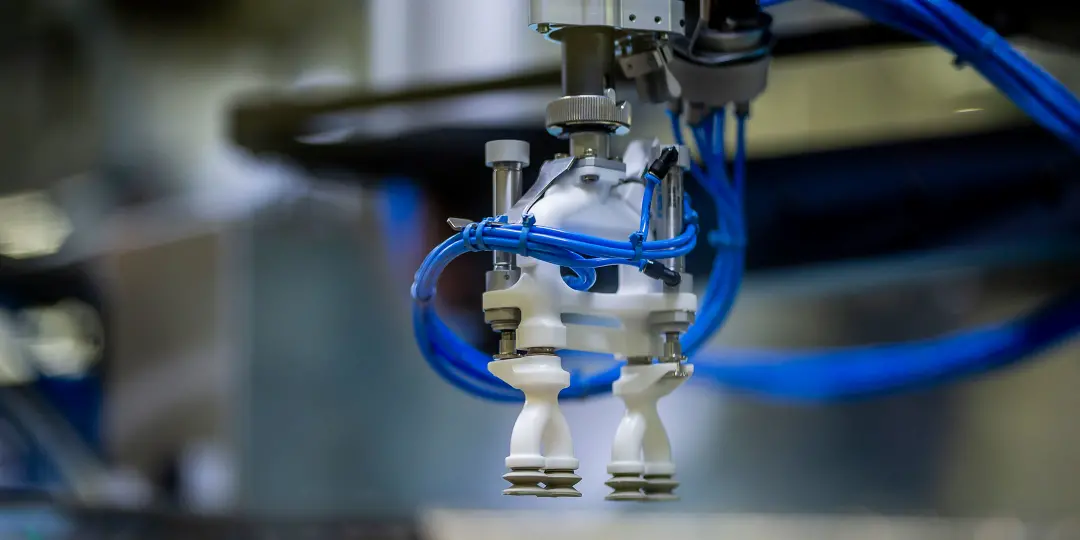

One tool inside a Schubert top-loading packaging machine, for example, is used to gently handle delicate products, ensuring that they remain in good condition.

A tool inside a Schubert machine used to gently handle products

Trivium, meanwhile, uses carbon-reinforced nylon to create a “worm” tool that guides tin cans down a production line.

Want to learn more about identifying high-value 3D printing applications? Check out our guide to finding the perfect application for you.

Download the Ultimaker Application Finder

Leave A Comment