PT. Meiwa Mold Indonesia (hereby referred to as Meiwa Mold) is a company engaged in die-casting mold manufacturing. Its customer base is diverse, including prominent names like American Toyota, Astra Daihatsu (ADM), HPPM (Honda Precision Parts Manufacturing), and Yamaha.

Meiwa Mold recognizes the importance of delivering high-quality molds to meet their customers’ strict requirements. To ensure accurate machining of castings, machining allowances must be tightly controlled. An excessive allowance will raise the machine’s weight and the use of materials, equipment, and energy. That’s why they invested in SHINING 3D’s FreeScan UE Pro metrology 3D scanner for machining allowance inspection, sourced through PT EVOLUSI KREASI INDONESIA, a trusted partner.

What challenges did Meiwa Mold face?

Before integrating FreeScan UE Pro into their machining margin inspection and analysis process, Meiwa Mold faced a major challenge: scanning medium to large objects. They already had a CMM for small and precision mold inspection and a structured light scanner, but neither was portable enough. With limited space, it was inconvenient to move large and heavy objects.

How does the FreeScan UE Pro help Meiwa Mold be more efficient?

To address the challenges, Meiwa Mold implemented the FreeScan UE Pro metrology 3D scanner from SHINING 3D. This industrial 3D scanner improved their mold quality control efficiency in the following ways:

Easy Operation

The FreeScan UE Pro handheld 3D scanner is portable, lightweight, and ergonomic. Users can carry it around large objects for handheld scanning at any time. Its user-friendly 3D scanning software is easy to operate and offers a short learning curve.

The FreeScan UE Pro 3D scanner

Suitable Scanning Modes

The FreeScan UE Pro is equipped with three scanning modes: multiple lines scan, single line scan and fine scan. Among them, the 13 cross-laser lines in the multiple line scan mode are ideal for fast 3D scanning of large objects. This is key for plum molds where large molds must be captured.

One of the company’s mold quality control subjects.

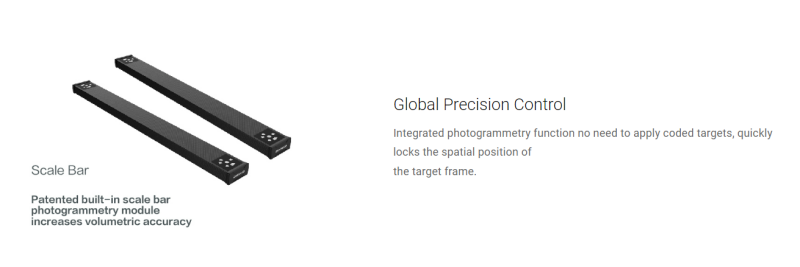

The FreeScan UE Pro also offers a photogrammetry function. All you need to do is place the scale bar on the surface of the object and move the FreeScan UE Pro around it. This feature increases volumetric accuracy.

Metrology-Grade Accuracy & Fine Details

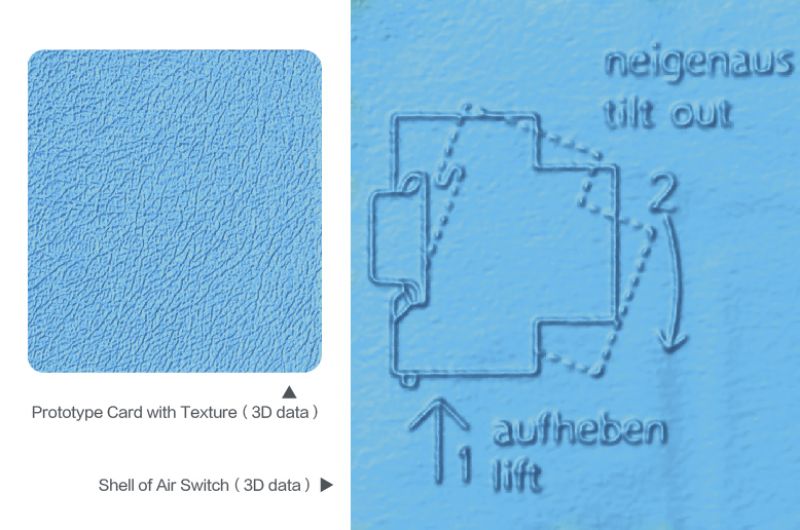

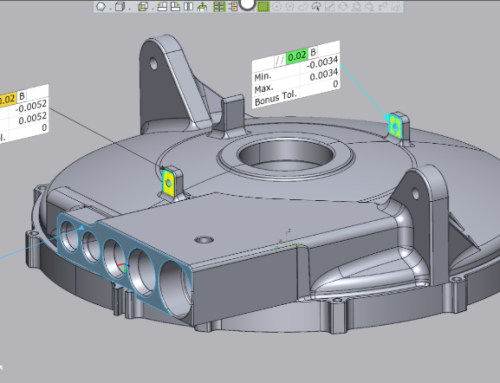

With an accuracy of 0.02mm, the FreeScan UE Pro supports Meiwa Mold with consistent, highly precise mold scanning results. Its high-resolution camera and 5 parallel laser line mode enabled Meiwa Mold to obtain accurate dimensional data, including complex geometries and fine details that were previously challenging to measure.

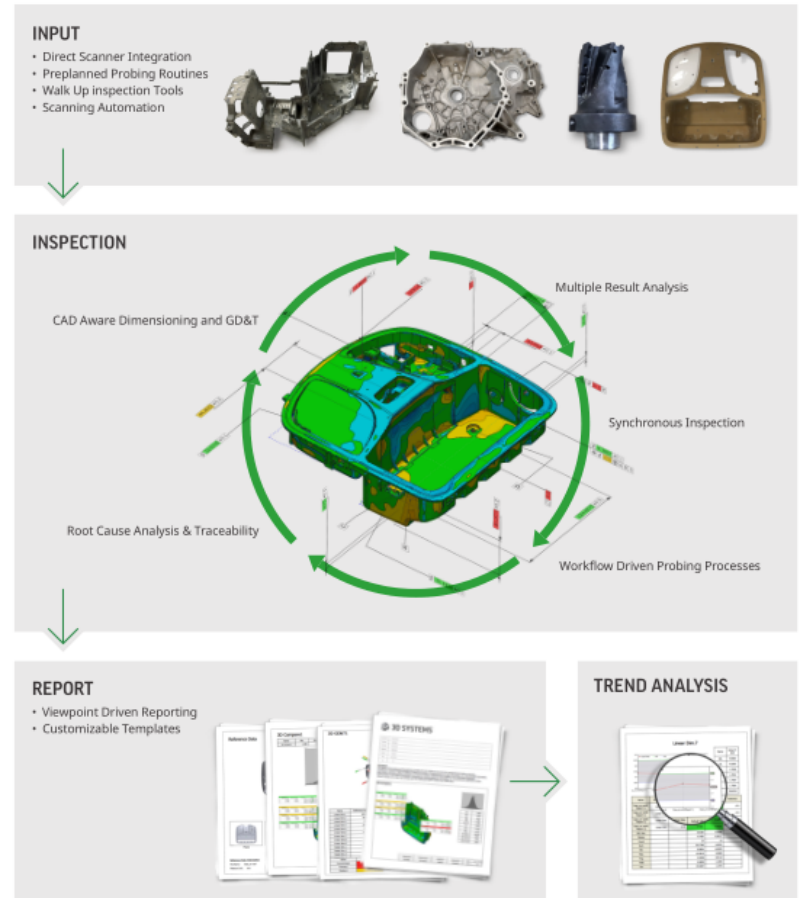

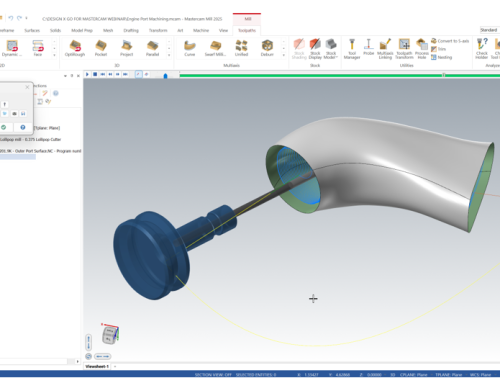

Seamless Exports to Inspection Software

The scan data can be imported into all mainstream 3D inspection software, such as Geomagic Control X, with one click. Through these software packages, Meiwa Mold can compare the scanned mold with the CAD model, identify deviations, and conduct thorough analyses.

Conclusion

Meiwa Mold’s machining allowance process used to be tedious and time-consuming. With the FreeScan UE Pro, the team can quickly and easily 3D scan all around its large molds. Plus, this industrial and metrology-grade SHINING 3D solution FreeScan UE Pro Metrology 3D Scanner

Do you feel that your current 3D inspection system is becoming inefficient or outdated? Click below for more details on this scanner and more information on how Cimquest can help you implement it.

Leave A Comment