This article will discuss the fluid tightness of HP Multi Jet Fusion parts and show some real-life examples.

HP MJF parts have been proven to be watertight without any additional post-processing, therefore parts can be used to have liquids or gases flow through designed channels.

There are several variables that can be looked at to determine what a part can withstand.

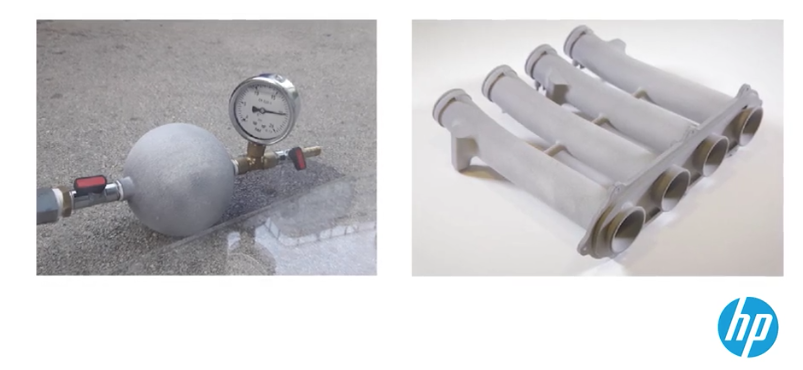

Using these variables, HP has conducted multiple tests with HP’s 3D High Reusability PA 12, tests that prove spherical shapes will hold higher pressures.

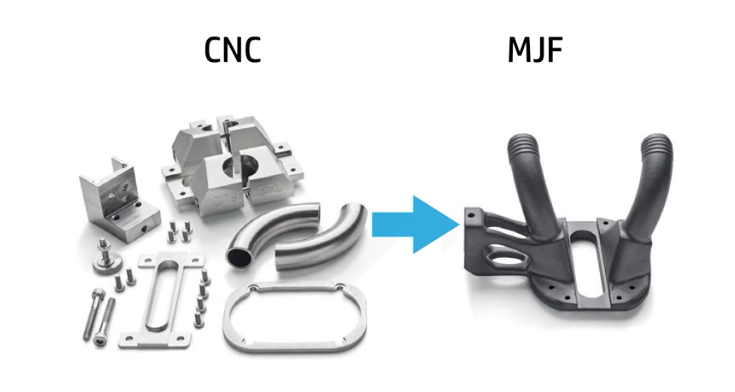

Additionally, the design freedom of 3D printing helps to improve the efficiency of these components. For example, ducts can be unified and optimized for better product space due to geometries not possible with other technologies. There is also a greater level of customization possible among assemblies.

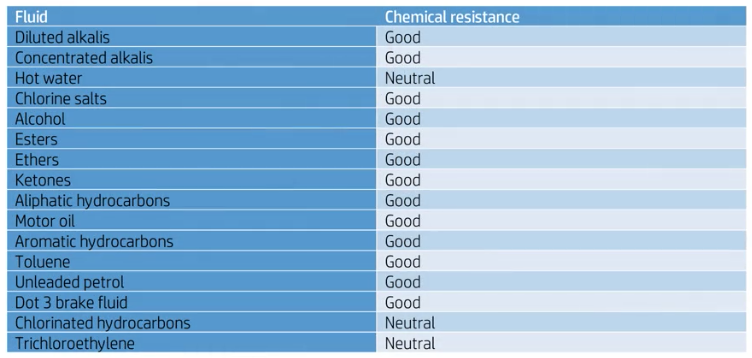

Along with the structural strength of HP MJF parts, PA12 has a high chemical resistance, making it ideal for interaction with many fluids. This chart shows some of the fluids that have been tested.

Now, let’s take a look at several examples of MJF parts that are in use today:

First, inside the JF 4200 there are over 60 MJF parts and one of these is this air duct. This is several parts consolidated into one to provide internal airflow to the printing carriage.

Next you can see the use of this end of arm tool, the part was redesigned for MJF and allows for a vacuum through the component to place the sticker on each apple.

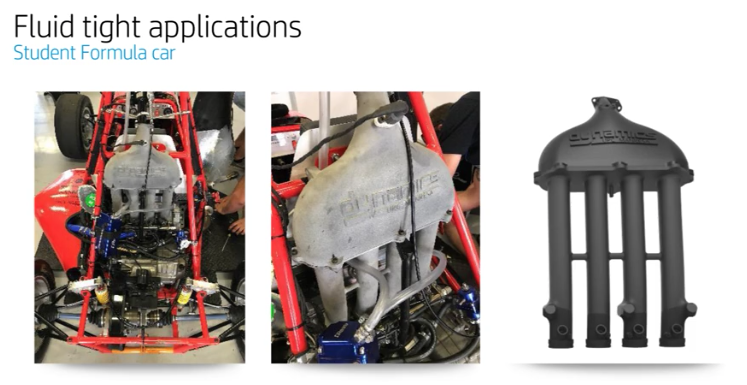

A European college used the MJF process to design an intake for their race car.

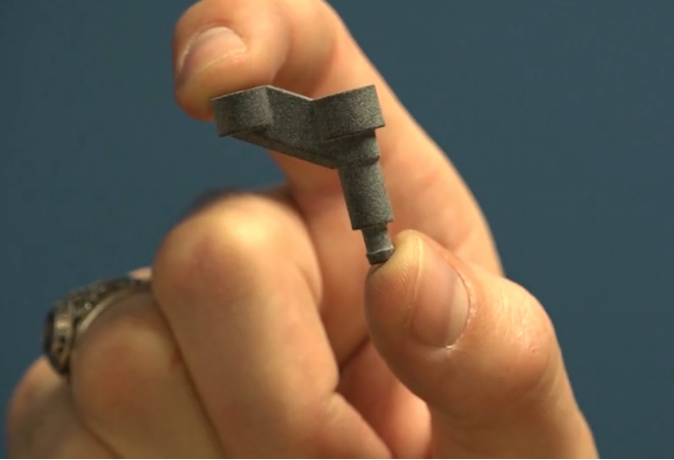

Pneumatic end arm grippers – air tight and each part will cycle 1,000,000 times.

This drill extraction shoe was optimized for multiple parts for enhanced fluid flow.

As you can see, HP Multi Jet Fusion provides an alternative for making fluid tight parts for electrical and mechanical applications. These are injection mold quality parts, created in hours with no tooling.

Please be sure to sign up for our 2 Minute Tuesday video series to stories like this one in video form every week. More info at the button below.

Leave A Comment