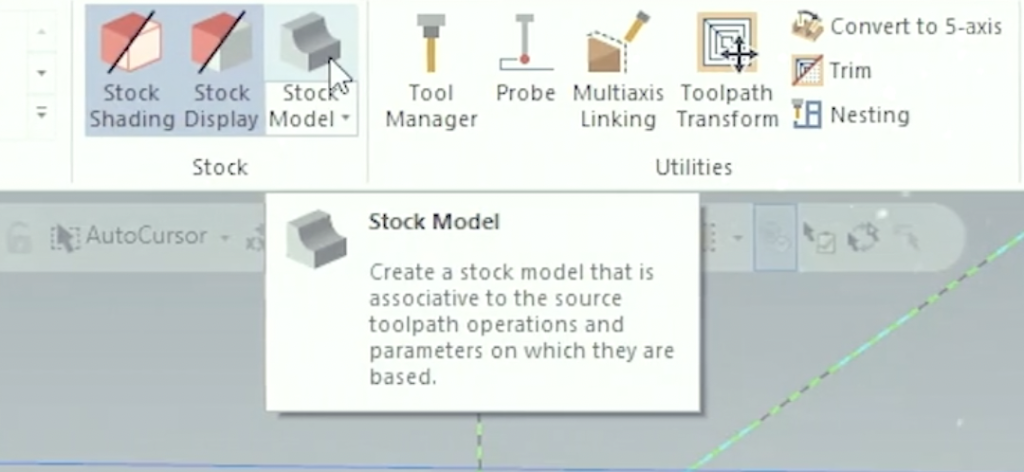

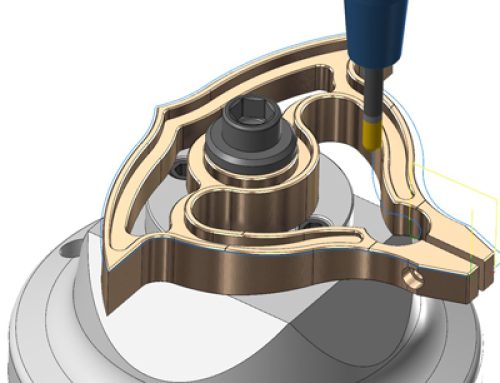

This blog post will demonstrate the importance of using the Mastercam 2023 stock models in 3D machining. First, let’s explain what a stock model is. Stock Model is a utility that allows you to create a “snapshot” of the workpiece at any given point during the machining process. This “snapshot” can then be used to streamline toolpath motion for irregularly-shaped stock and re-machining operations.

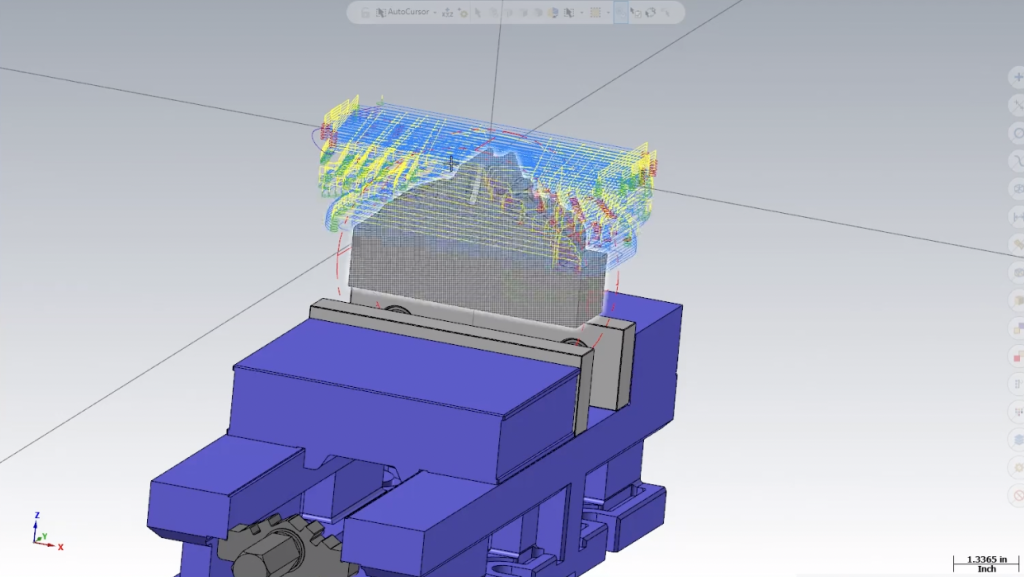

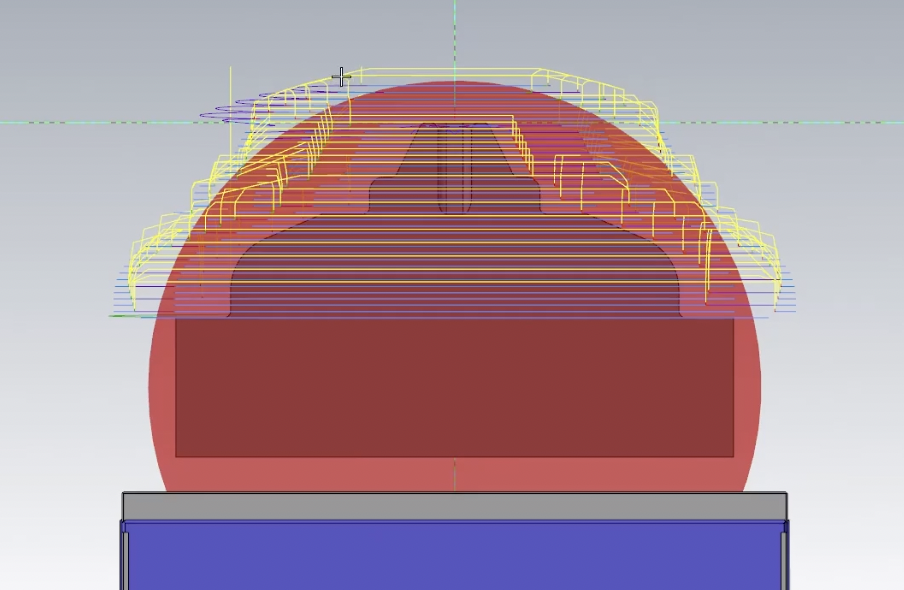

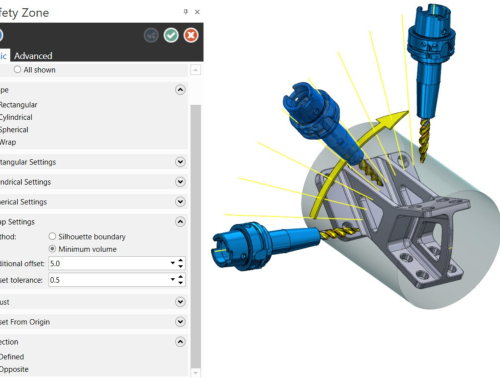

In this example, we will use a 3D High-Speed Area Rough toolpath setup to rough the part with a High feed mill. When we look at the toolpath from the front view and turn the stock shading on, we can see that there is an excessive amount of air cutting.

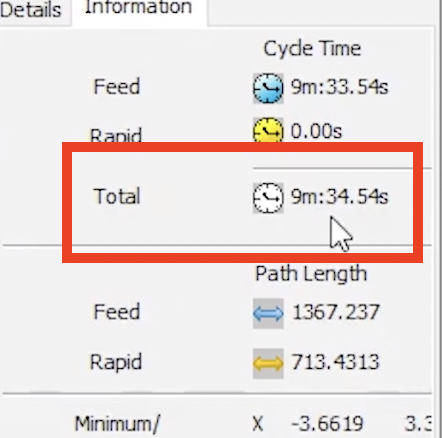

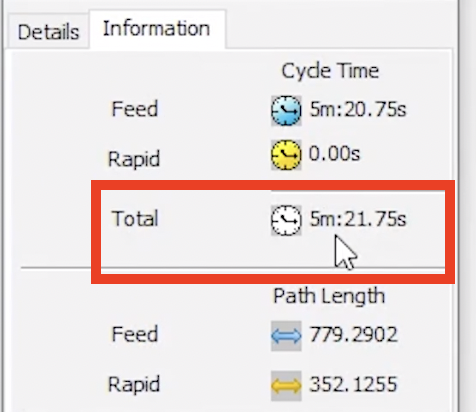

Take note of the cycle time.

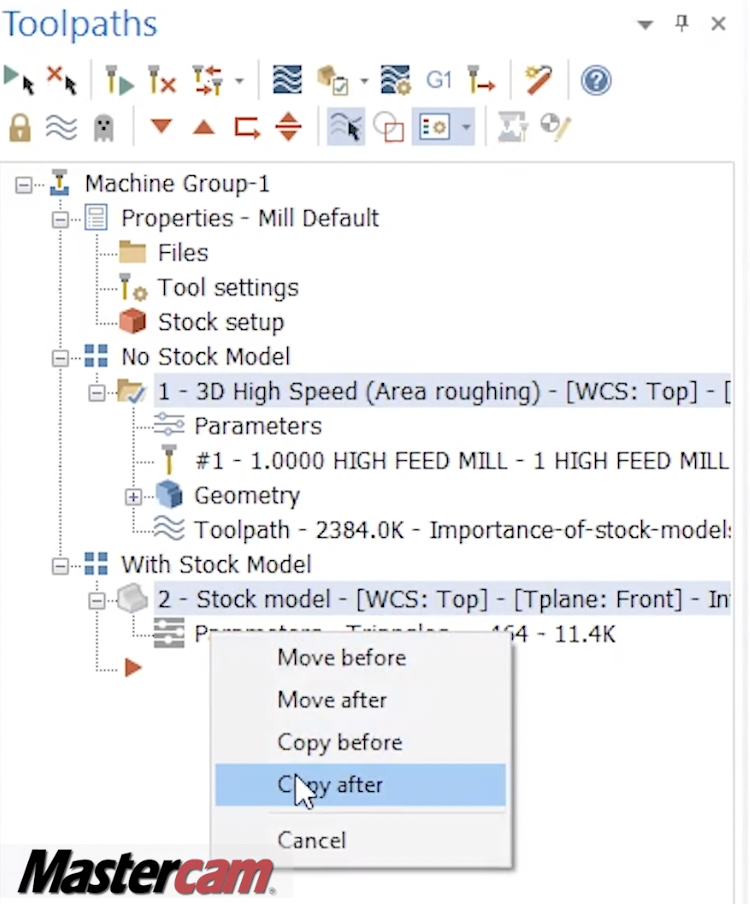

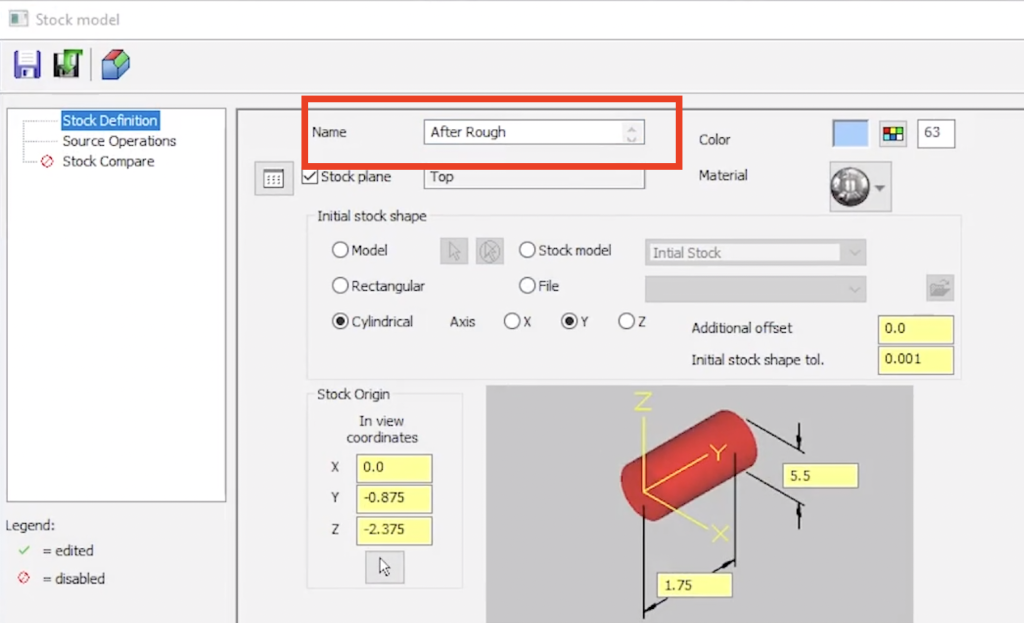

Now we need to create a stock model to represent the initial cylindrical stock shape. Right-click and drag the original toolpath onto the stock model and select Copy After.

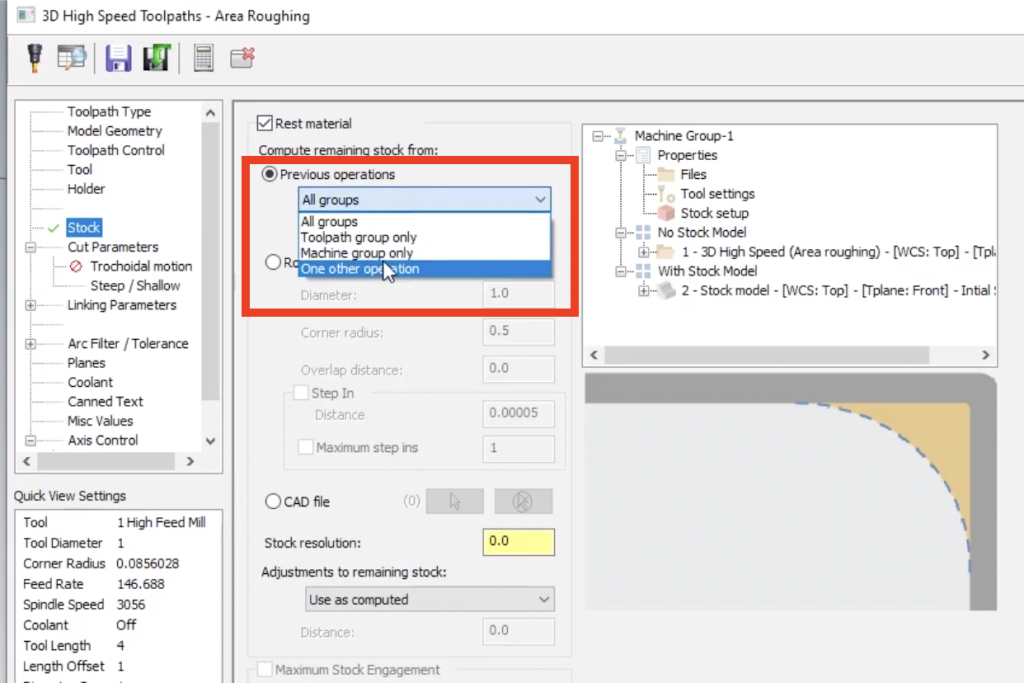

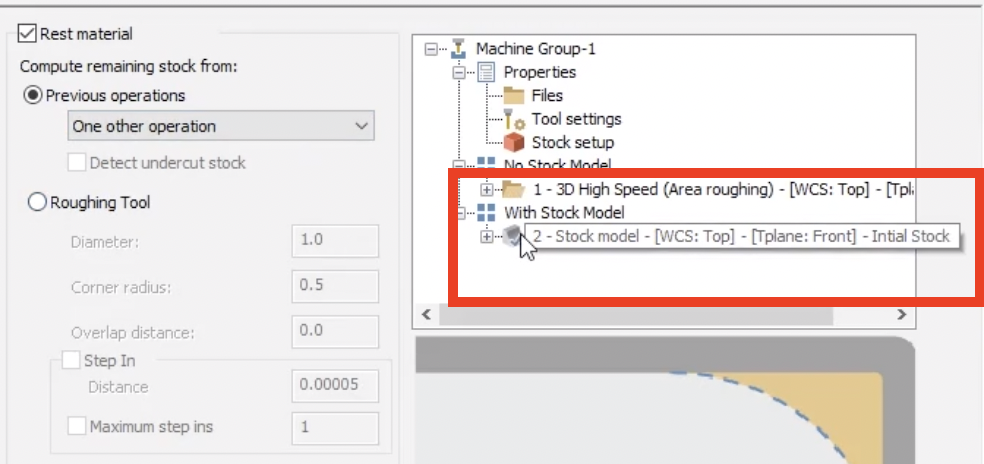

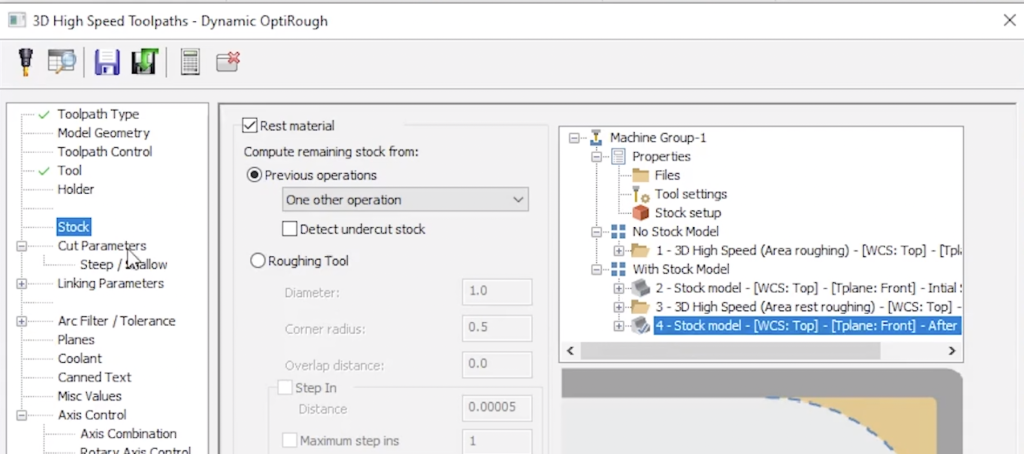

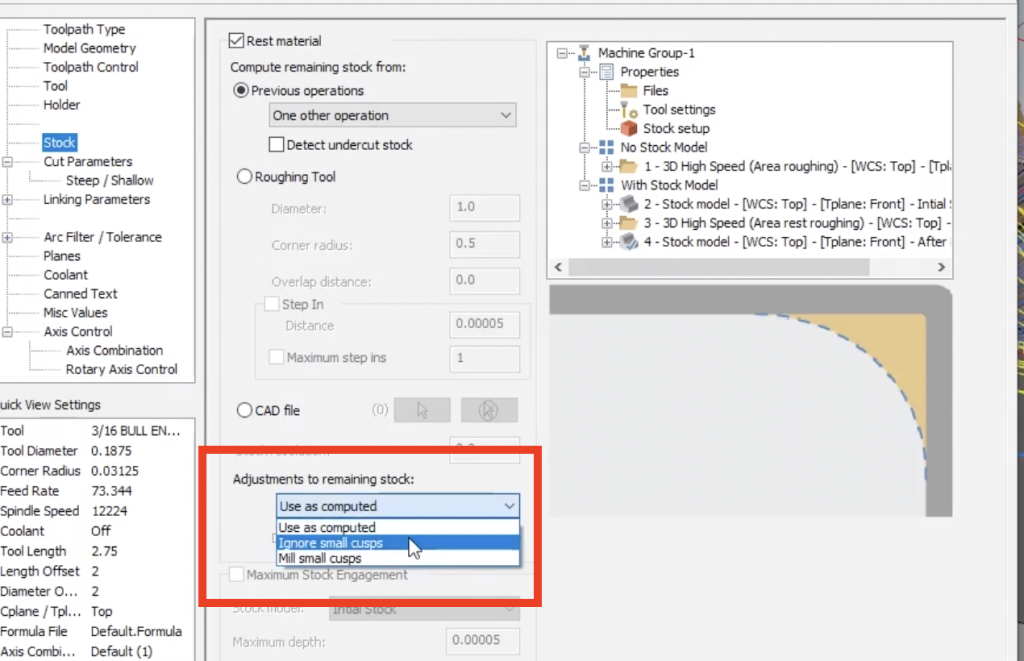

Open up the Toolpath Parameters, go to the Stock page, turn on Rest Material, select One Other Operation, and select the stock model.

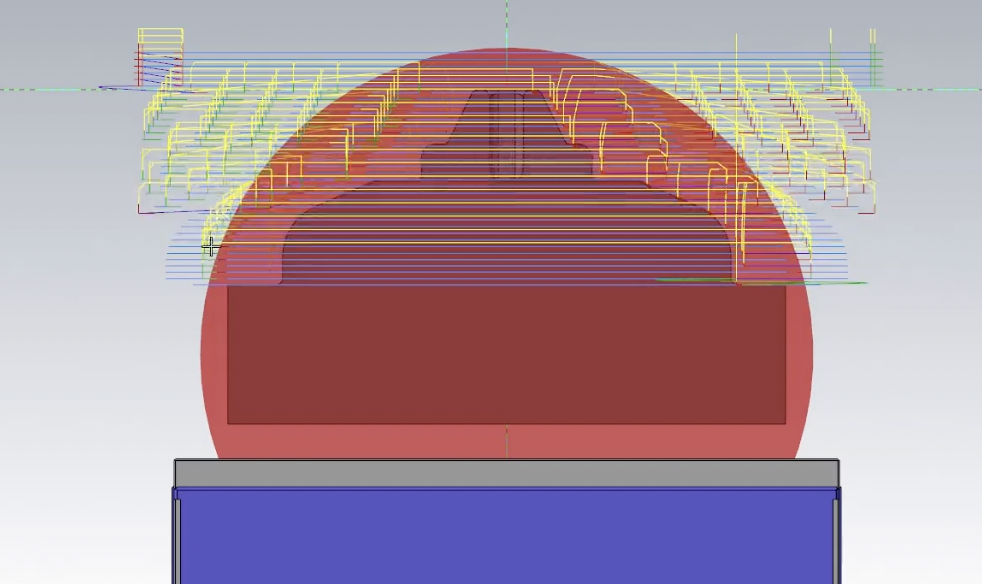

Now, when viewing your toolpath again from the front view, you can see that it has removed all the unnecessary air cuts and reduced the cycle time by just over four minutes.

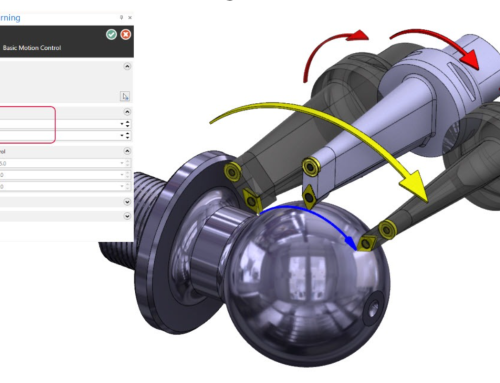

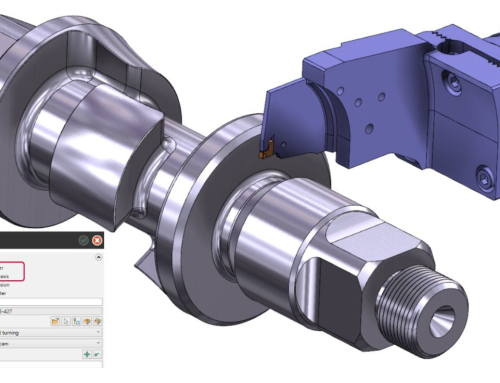

To make one more stock model for after the roughing operation, copy down the Area Mill toolpath, convert it to an Opti-rough, select a smaller tool, and set the rest material to the After-rough stock model.

As you can see, stock models are a powerful tool for improving toolpath motion and decreasing cycle time. Please be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below.

Leave A Comment