Let’s take a look at how to incorporate 3D packing software into your plastic powder workflow. While most machines come with their own packing programs, Materialise Magics can be a fantastic addition to your process. In this post, we’ll explore an example of a build for Formlabs, XYZprinting, and HP plastic powder printers that were packed in Magics.

Magics is a mesh manipulation software that specializes in 3D packing. The program uses the geometry of your model to efficiently pack your parts, whereas other programs simply use the bounding box of your models. Due to this, Magics is able to increase the packing density of your builds, reducing the overall waste material that you generate and the time needed for printing.

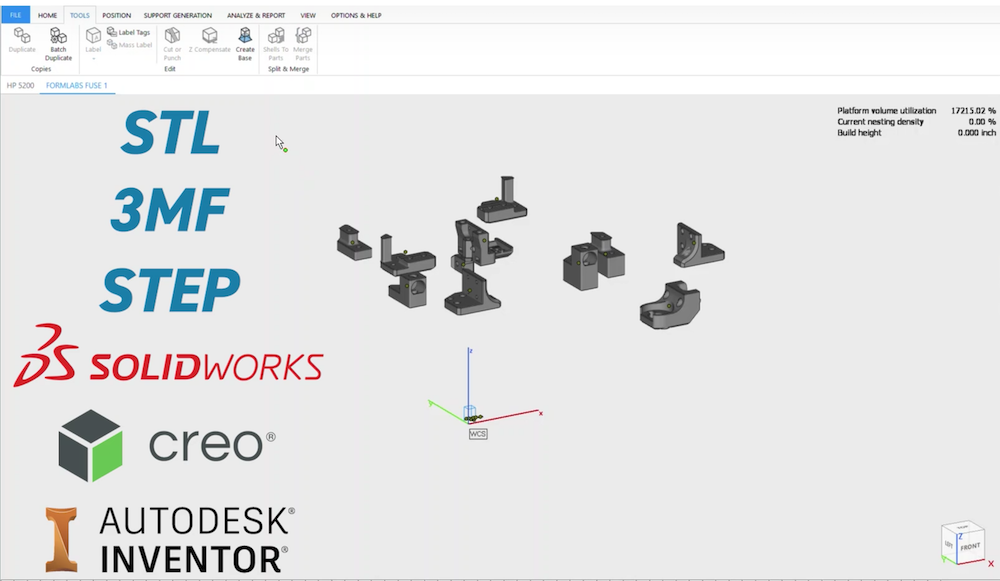

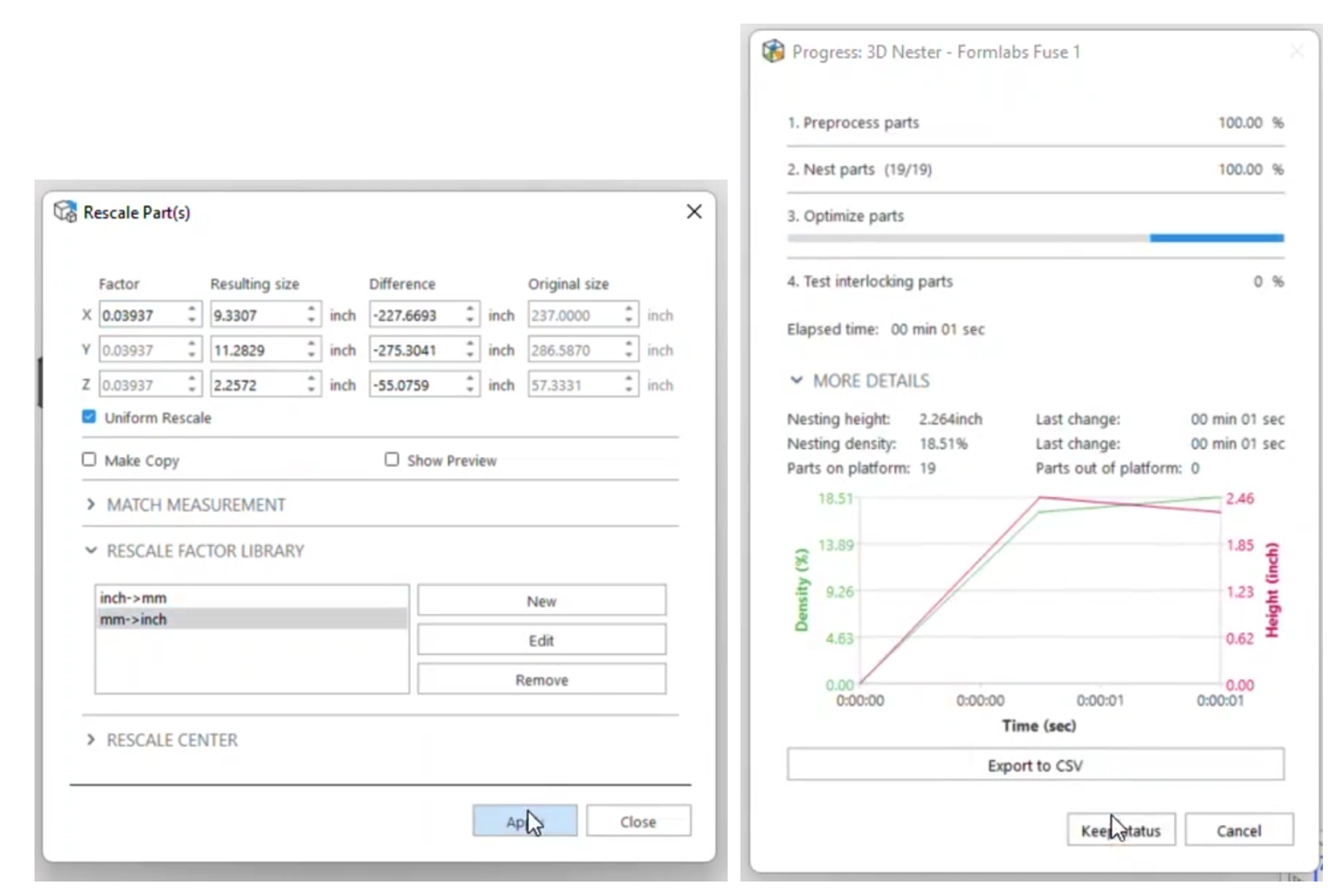

The first thing you need to do is import some files into the program. Magics can interpret almost every 3D file type including STL, 3MF, STEP, Solidworks, Creo, Inventor, and other native CAD files. When using STL files, you will need to confirm the sizes of your parts, since the file type holds limited information on the units. Using the handy scaling tool, you can convert between millimeters and inches with the click of a button.

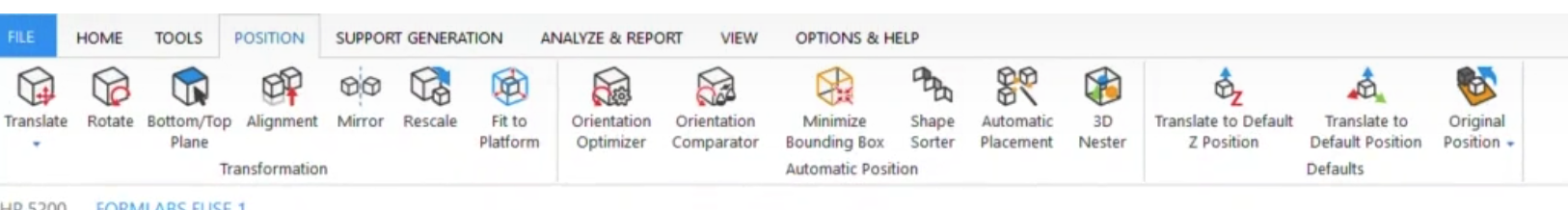

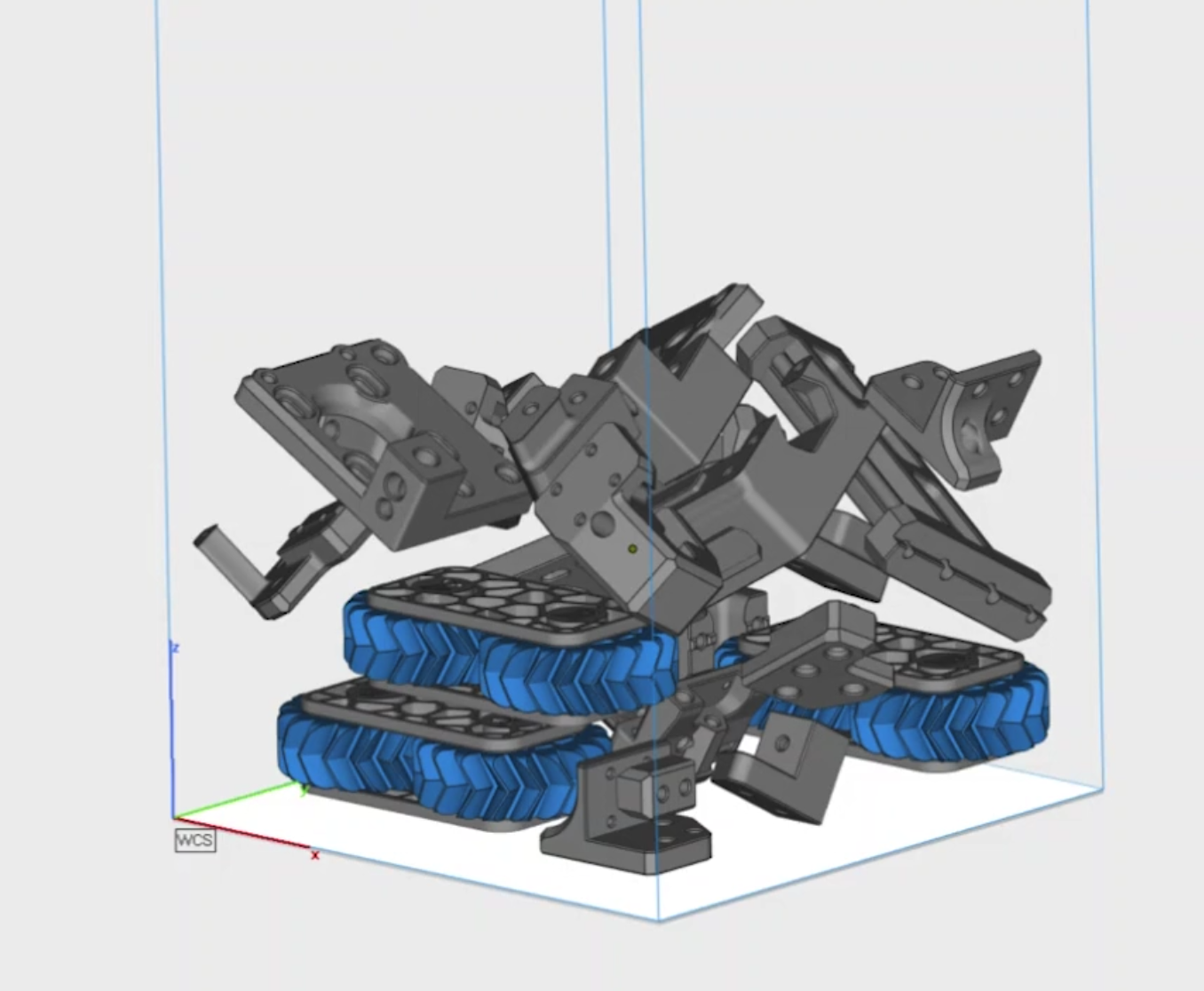

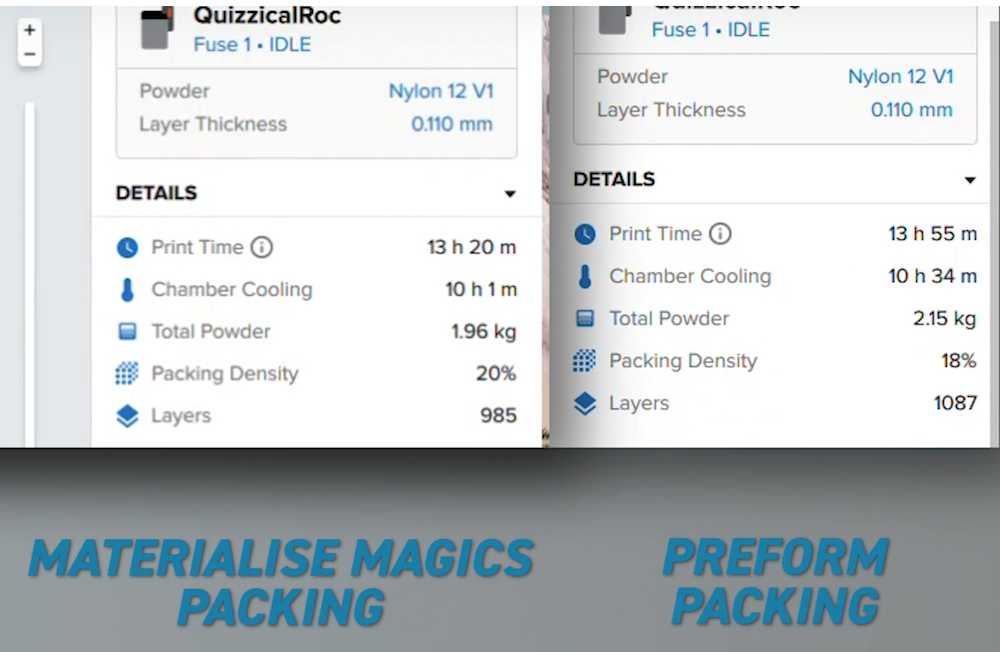

After importing, the next step is to orient the parts for the best printing success. In our example, gave both PreForm, the Formlabs packing software, and Magics the same model criteria and orientations. This gave us an apples-to-apples comparison between the two.

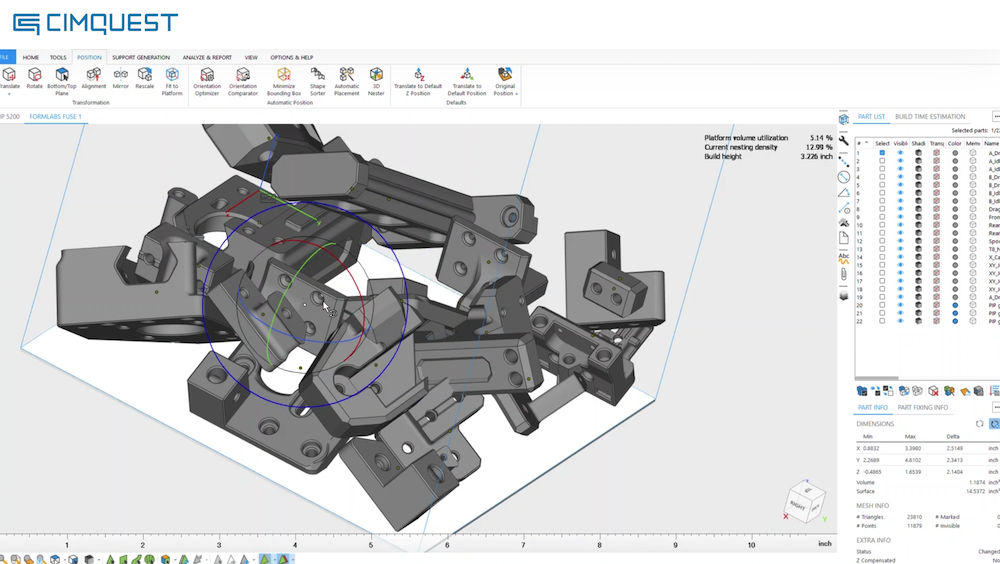

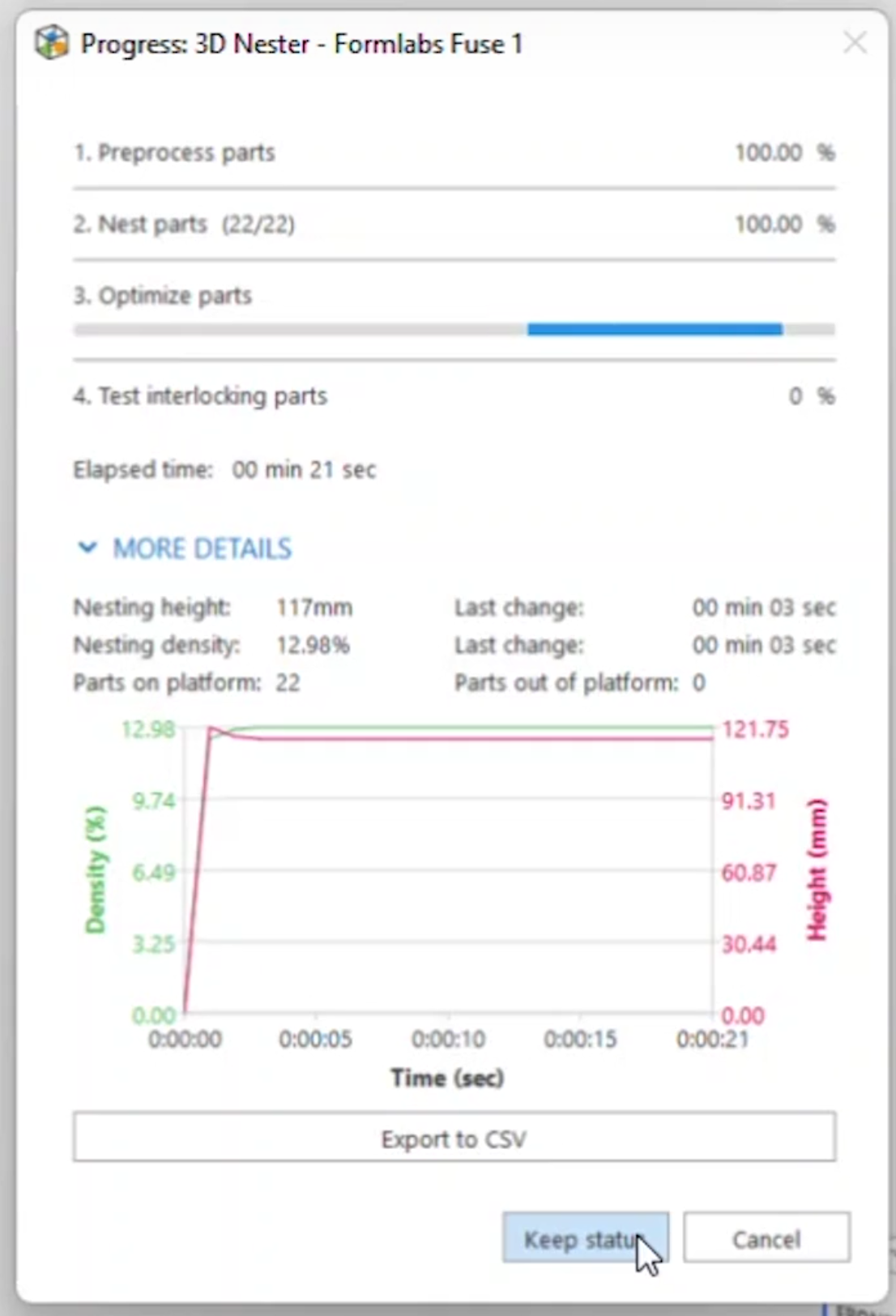

Once the parts were oriented, they were ready to be packed. The 3D nesting tool provides a plethora of options to choose from.

For the highest efficiency, pack your models by their geometry as opposed to the rectangular bounding box. This allows parts to interlock and fill cavities in ways that would not be otherwise possible. In terms of packing criteria, there are three options:

- The packing can run indefinitely until stopped.

- A time limit can be utilized.

- The program can stop packing after a certain density has been reached.

Typically, we prefer letting the program run for a few minutes until the packing is no longer showing signs of movement. At this point, you should select keep status of the pack and hit OK.

When the models are packed into place, you can merge them into one STL file. This STL file can now be sent to your printer of choice’s slicing software to be uploaded.

When comparing the two different packs in PreForm, it is clear that using the Magics build significantly lowers the printing time and increases the packing density. An entire 30 minutes were shaved off of the print time and the powder usage was reduced from 2.15kg to 1.96kg. In this instance, that equates to approximately a $20 savings!

As you can see, Magics is a unique program that can help optimize your workflow, minimizing wasted space and time. This only scratches the surface of what the full program can do. Magics also excels at creating support structures for both SLA and DMLS printing processes, becoming the industry standard. The mesh manipulation tools can help repair broken STL models, split models for printing, hollow and lightweight models, and build lattice structures for infill.

Please be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below.

Leave A Comment