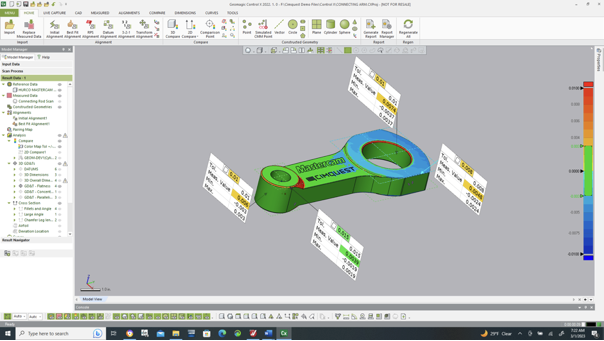

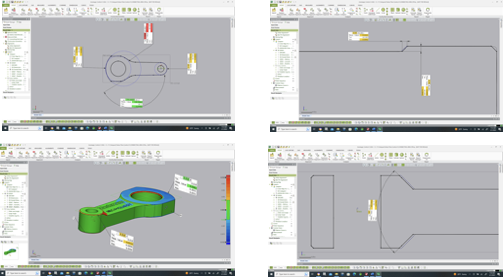

Control X is a powerful metrology product with dozens of inspection tools available including; 2D and 3D dimensioning, GD&T analysis, color maps, Whisker plots, and many more. After all of the inspection tools are deployed for a specific inspection plan, you can create a date and time-stamped report, serialized for a particular part scan. This ensures that the inspection report of a single-part scan against a nominal CAD model is correctly identified and stored.

But how does this process work when you have 10, 100, or even 1,000 scans to inspect against the same nominal CAD model? Repeating the inspection process manually over and over again would be extremely time-consuming, not to mention very tedious. This is where the Control X Batch Processing comes into play! Batch processing is a workflow in Control X whereby you can launch an unmanned inspection process to be applied to as many part scans as required.

How Does Control X Batch Processing Work?

First, you prepare the inspection for the very first manufactured part scan. All of the inspection tools are deployed and applied to that very first part scan, including the all-important Initial Alignment followed by a Datum Alignment. The idea being the Initial Alignment will get the part scan “roughly aligned” to the nominal CAD model regardless of the scanning orientation. Then the Datum Alignment will dial in the final scan to part orientation and the inspection process may begin.

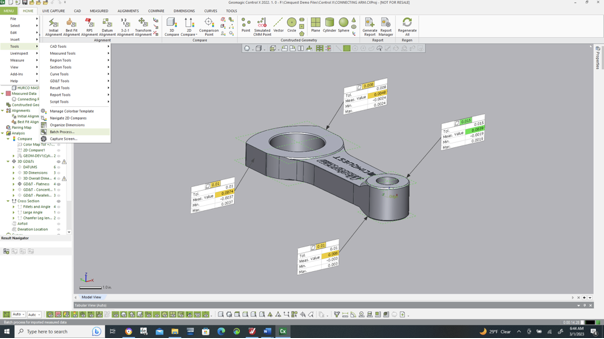

Once the inspection plan is completed for that first part, Batch Processing can be deployed. It is found under the Tools menu.

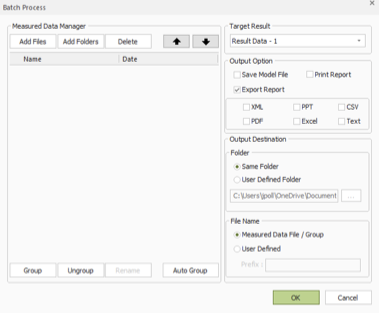

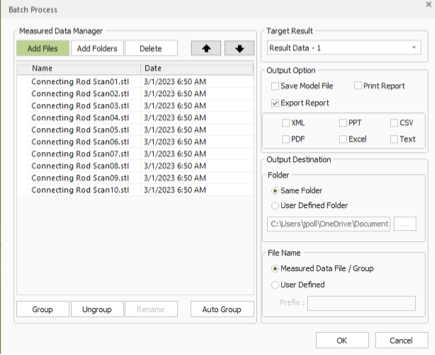

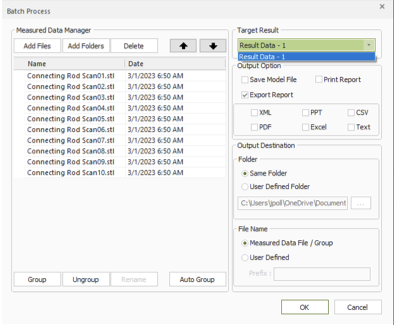

Once selected, the following dialog appears, enabling you to control every aspect of the inspection for every part scan in the batch.

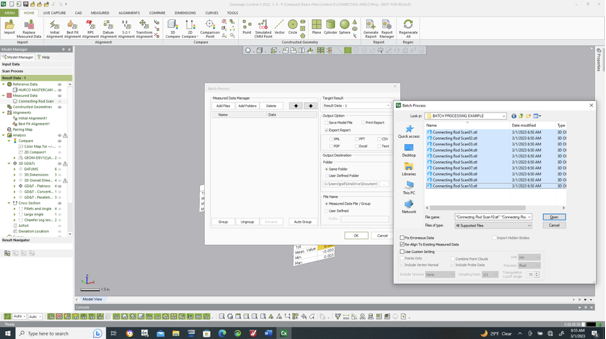

The Add Files/Add Folders/Delete tabs allow you to add as many scans to the batch as needed. The up/down arrows move scan files up or down in the processing order. Below we simulate the selection of ten (10) connecting arm scans, indicating to the process that it will be inspecting all ten against the same inspection plan.

The scans are then loaded into the Batch Process dialog.

Each inspection process in Control X can have multiple Results files, but just one of those files may be used in any single Batch Process.

For Output Options, if the Save Model File option is checked, the Batch Process will create a unique Control X CXPROJ file for every scan in the batch. More commonly, you can choose to just Export Reports and select the report format(s) desired (PDF, Excel, and so forth).

You can then determine the folder where the reports will be stored and you can even select custom prefixes for each inspection report, further enhancing the identification process to ensure each inspection report is serialized properly.

This means that you can launch the process before leaving work at night and when you return in the morning, dozens to hundreds (or even thousands) of part inspections with associated, serialized inspection reports can take place overnight, completely unmanned. You can be working while you’re sleeping!

Please contact Joel Pollet for any questions.

Leave A Comment