Choosing a scanner for metrology is a topic that comes up often when companies look to deploy non-contact inspection and question what criteria they should use when choosing a scanner for their company. We have covered this topic in detail at some recent Cimquest events but have had several customers ask more questions. Here are some of the highlights of these presentations.

Accuracy vs Resolution

Accuracy is the accuracy of the points acquired on the surface being scanned for inspection. An accuracy of +/-.001” would indicate that the maximum distance of the acquired (scanned) points is less than or equal to +/-.001”.

Resolution is the scanner’s ability to capture fine detail. Please note that resolution is often referred to as ‘Point Spacing’ or Point cloud density. By definition, resolution is the shortest distance between any two points in the scan file.

So if the very best resolution of a scanner is .010” that means the shortest distance between any two points in a scan can not be less than .010”. Keep in mind that ultimately small triangles are formed by connecting up three of these points to create a mesh. So another similar definition for resolution would be that no triangle leg in the mesh can be shorter than .010”.

Consider the tiny chamfer on this hole below. The chamfer size on the CAD model shown is .010”.

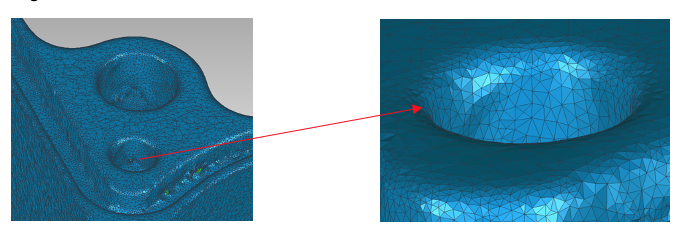

We scanned the chamfer with two different scanners, both having the same +/-.0012” accuracy, but one having an .008” resolution and the second having a .002” resolution, noting that the smaller the number, the higher (the better) the resolution. Below are a few images of the scan of the chamfer taken from the physical part. At an .008” resolution, the chamfer gets ‘washed out’ and looks more like a radius. This is because the point cloud and resultant mesh connecting up the points is just about the side of the .010” chamfer. So each sharp chamfer edge gets washed out and the resultant model looks like this. In a nutshell, the triangles representing the chamfer are too large to accurately represent the shape. Or you can think of the vertex points as being too far apart. A good rule of thumb is . . . if a scan looks to be ‘melting’, it generally means the resolution of the scanner wasn’t high enough.

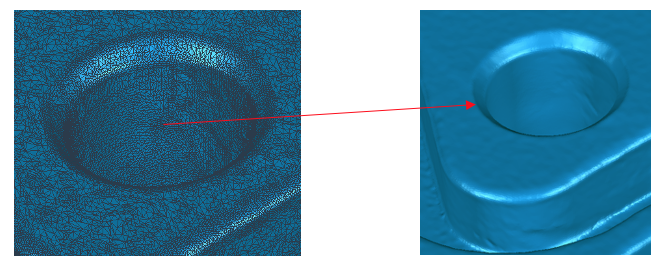

Now using a scanner with the same +/-.0012” accuracy but a .002” resolution, the resultant chamfer looks much more like a chamfer than a radius and may be measured. Below is the chamfer scan both with mesh edges turned on and off. You can see that the .002” resolution produces a much more dense point cloud and subsequently tinier triangles to form the shape of the chamfer far better. Notice still that the sharp edges of the scanned chamfer are still slightly radiused. Using a scanner with even higher resolution would get those corner sizes closer to sharp, although as scanned data, they can really never be totally sharp.

If inspecting chamfers of this size is a critical part of your inspection process then being able to scan and capture this fine detail would also be very important to you. The second scanner would likely work out for you whereas the first would not be adequate. Please reach out to Joel Pollet for more information

Leave A Comment