Cylindricity – Similarities & Differences Between Related Callouts

While this month’s segment is focused on Cylindricity we will also review several of the GD&T Callouts discussed previously (and a few not previously discussed but relevant to this month’s discussion) along with some of the similarities, as well as subtle differences between them.

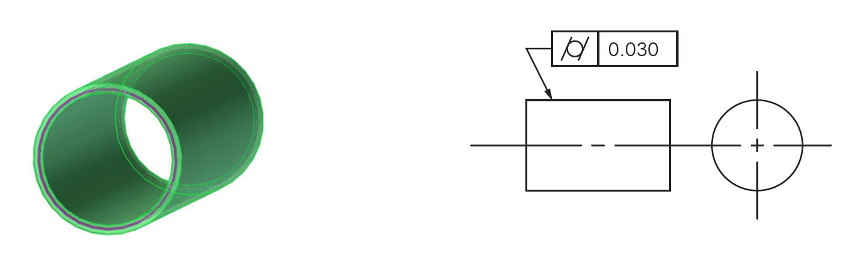

Cylindricity is a form of control tolerance that dictates both the roundness and center-axis straightness of a cylindrical part. If you consider the shaded cylinder below, the thin purple curve represents the “perfect cylinder” and the green represents the acceptable tolerance zone for that cylinder’s cylindricity callout. A sample callout is shown as well.

Cylindricity is similar to Circularity (not discussed yet) however the latter relates to a single cross-section of the cylinder whereas Cylindricity refers to the entire length of the cylinder. This is very similar to the relationships of Flatness to Straightness where Flatness relates to the complete surface and Straightness is to a single cross-section, across the flat surface.

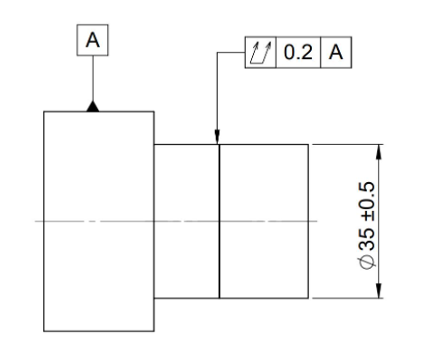

You will also notice a similarity of Cylindricity to Total Runout (described in a previous Metrology Minute). Circularity and Runout are also very similar as they both deal with the form of curves and not surfaces.

The most obvious difference between the two is that Total Runout must be defined in conjunction with a Datum callout but Cylindricity doesn’t require the reference to a Datum.

Please contact Joel Pollet at Cimquest with any questions.

Leave A Comment