When objects are scanned for inspection, Control X needs to be able to review the scan and extract analytic features from the scan. For instance, when measuring a radius, the software needs to be able to distinguish where one radius CAD feature ends and a new feature starts in order to perform an accurate measurement.

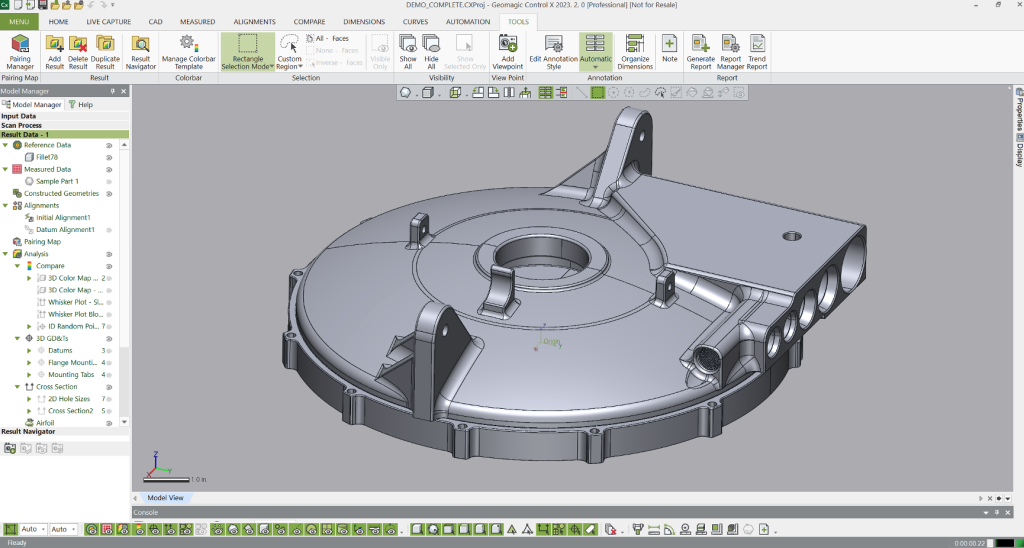

Using the CAD model below as it example, it is comprised of many analytic features, such as cylinders, planes, tori, etc.

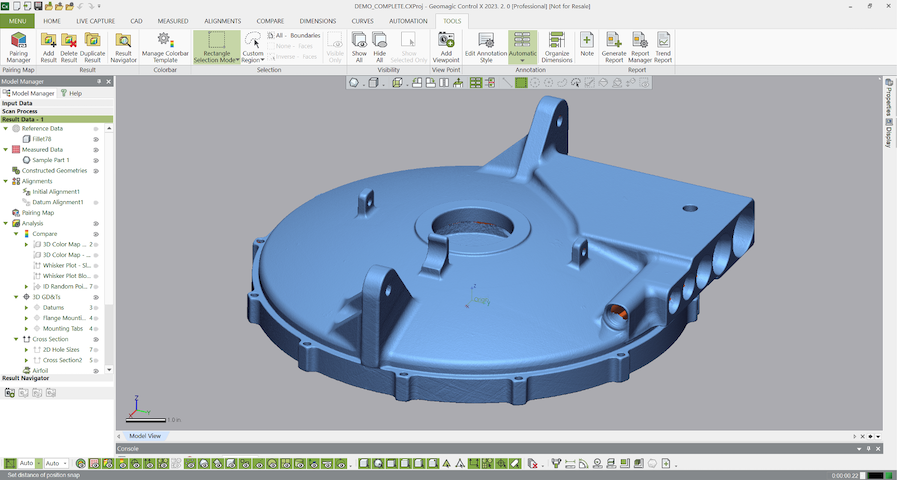

The scan of the manufactured part to measure looks like the image below.

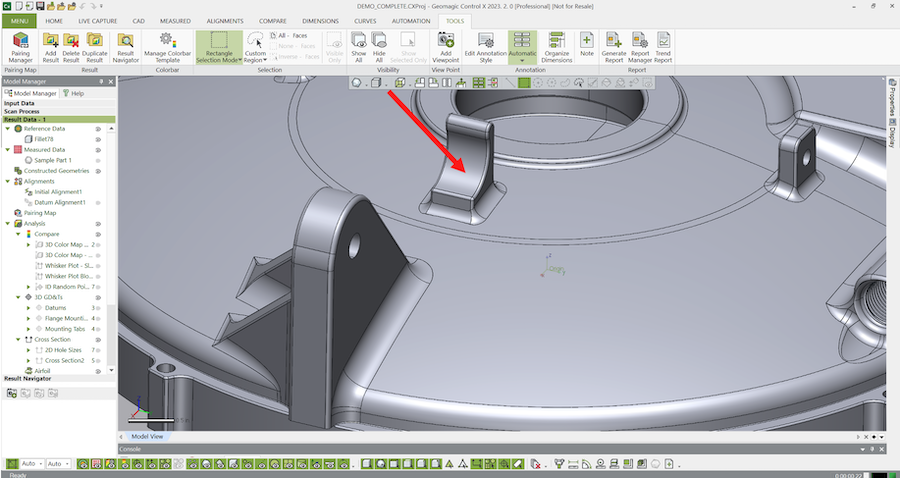

When the scan of a specific feature “overlaps” the edges of the feature, it can sometimes bleed into an adjacent feature and then the software can have difficulties distinguishing where one feature ends and the adjacent feature begins.

Let’s consider this machined feature shown below.

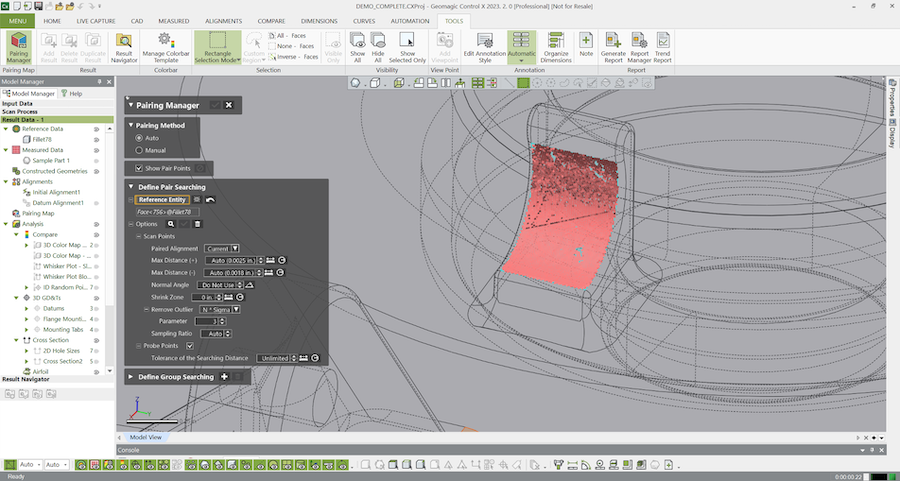

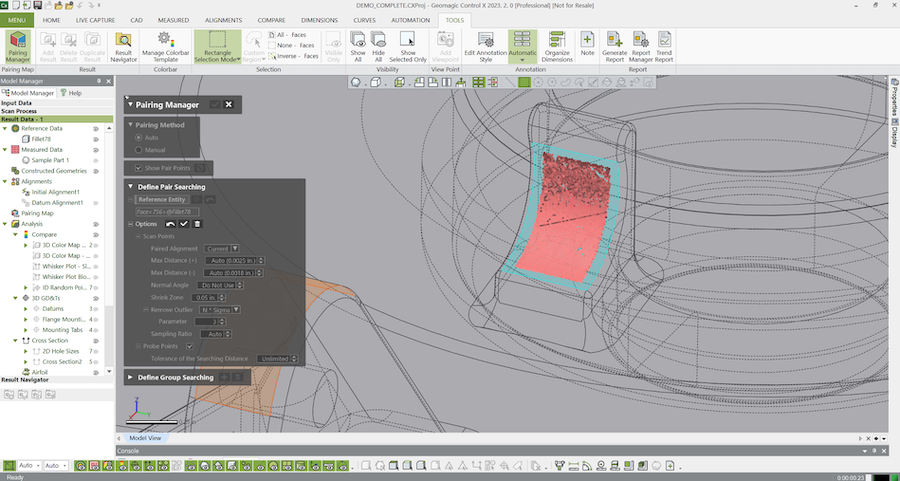

If we open the Pairing Manager and select that feature from the CAD model, we notice that the edges of the scan somewhat ‘bleed’ into the adjacent fillets all around the feature.

The overextended mesh can sometimes cause challenges for the GD&T dimensioning system. We can use the Pairing Manager to shrink the edges of the mesh back, to ensure that there is no ambiguity, and that Control X can definitely associate the correct mesh feature to the corresponding CAD feature.

In the illustration below, we shrunk the extents of the mesh by .050” and you can see the results where the red patch (mesh) is now “pulled in” from the adjacent features thereby removing any ambiguity as to the exact mesh section

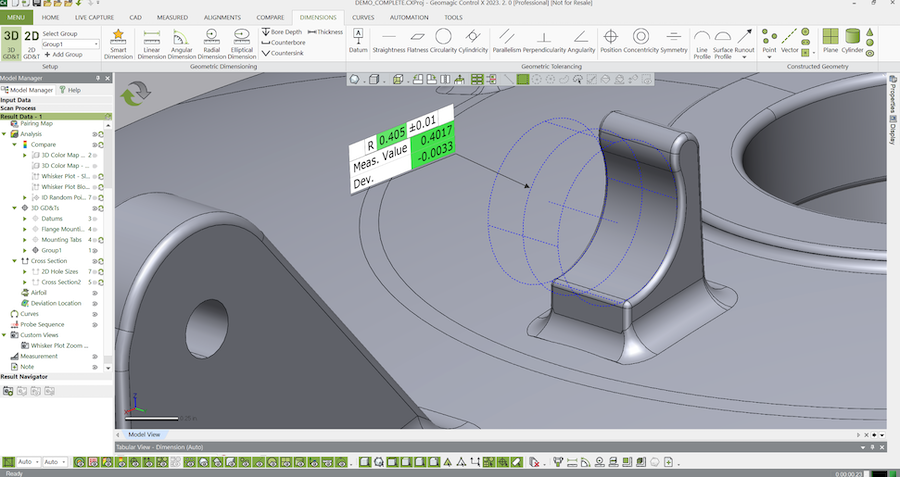

By adding a radial dimension, Control X can easily distinguish the CAD feature that the mesh feature is measured from.

Please contact Joel at Cimquest with any questions.

Leave A Comment