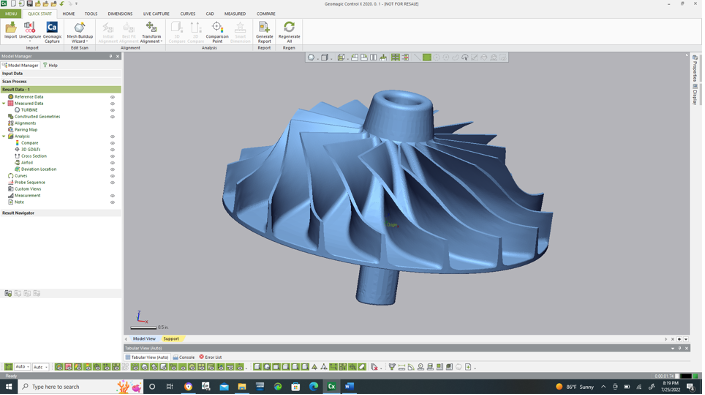

There are many analytical tools available in Control X under the Measure command that are extremely useful. This edition of Metrology Minute will explore common measurements that could prove useful to metrologists.

Measure Distance is a quick way of determining the approximate length of a blade, in this example, without going through the trouble of creating a 2D or 3D dimension. Just a quick vertex selection of opposing ends quickly returns an approximate distance.

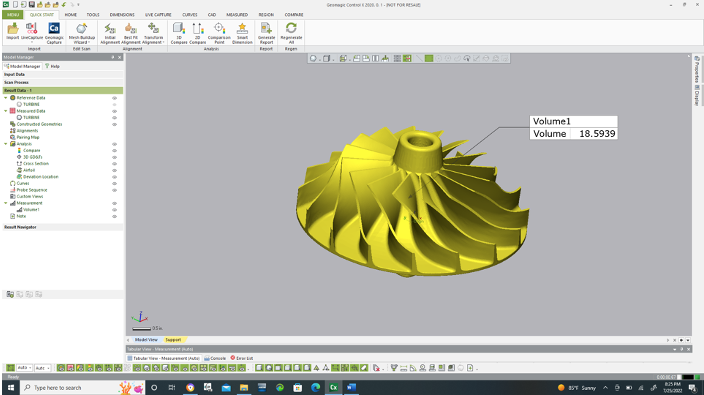

Measure Volume calculates the volume of material within a fully enclosed (sometimes called “a water-tight”) mesh file. This can be a very handy tool to explore the volume of material required to produce a 3D Printed model. Volume would be provided in cubic units (i.e., in^3, mm^3, etc.).

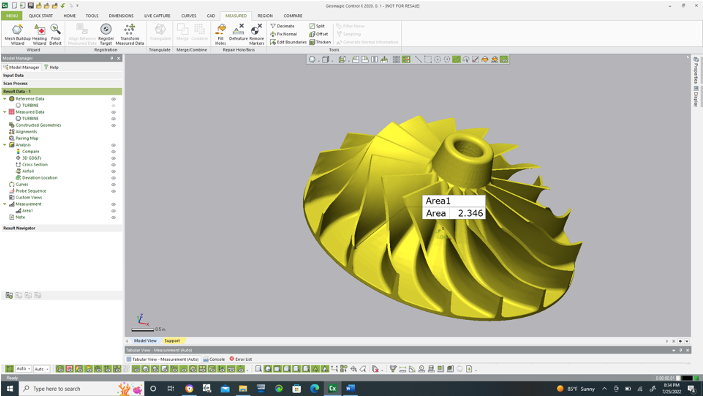

Surface Area can be a useful tool when measuring the individual blade surfaces. It can come in handy to determine the surface area of a blade on a turbine. Units here would be in^2, mm^2, etc.

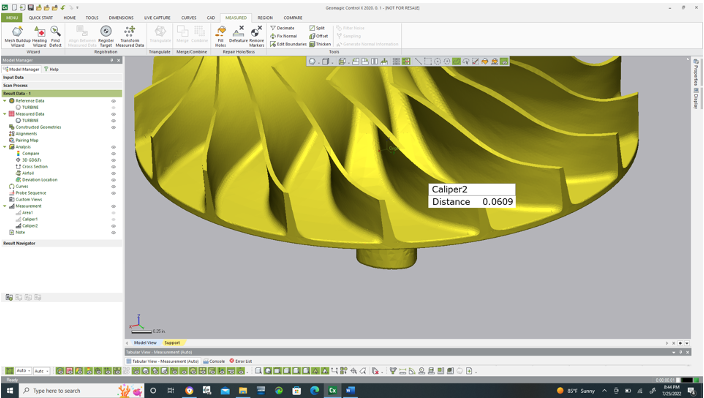

Lastly, Virtual Calipers can also prove very useful by simulating actual calipers on the model and taking random measurements. The image below illustrates measuring the width of the blade at the very edge of the model. The actual nominal value is .06” so this is a reasonably accurate measurement showing the usage of virtual calipers.

Just as a caution, the location of the virtual caliper can vary on the scan, just as it could vary on the physical part using actual calipers. Therefore, you should be cautious when utilizing these tools and recognize that they are all measuring “approximate” (scanned) data.

Please contact Joel Pollet of Cimquest for any additional information.

Leave A Comment