Have you ever considered reverse engineering a cabinet hinge replacement? Just imagine that you have a kitchen cabinet door with a broken hinge. Your wife wants to replace all of the cabinets since they are decades old, but you are determined to find a solution that doesn’t involve a completely new kitchen cabinet purchase and installation.

You remove the 20+ year-old hinge and take it with you to the local hardware store, in search of a replacement and you find hinges that are “oh so close” but just a slight difference makes it unusable. You come to the realization that your 20+ year old hinge probably just isn’t produced anymore so what do you do?

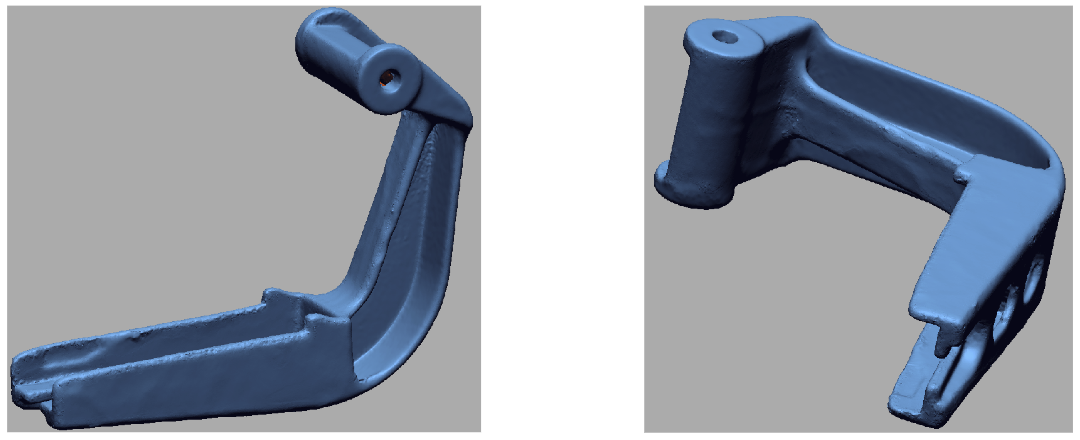

Step 1 – Scan the broken hinge

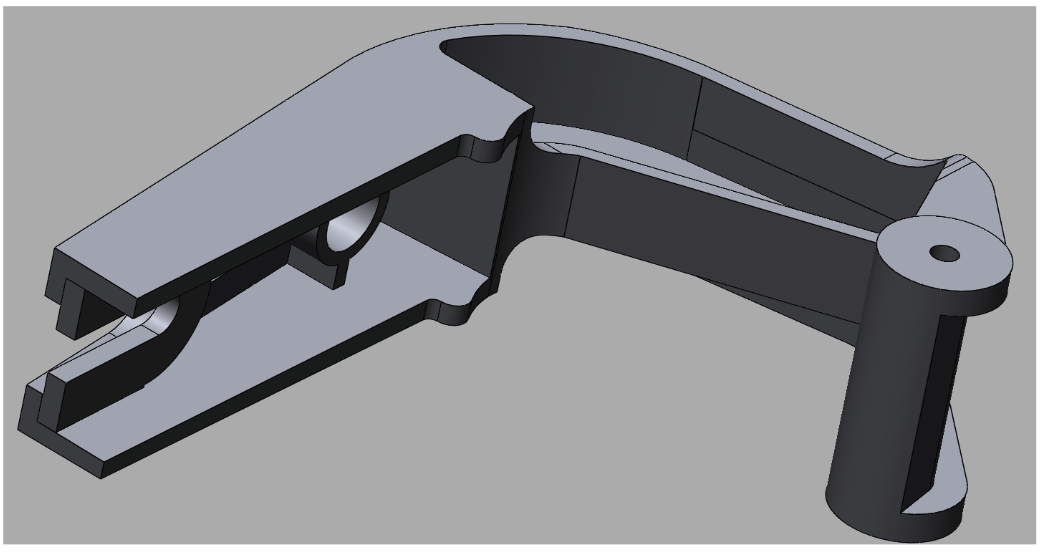

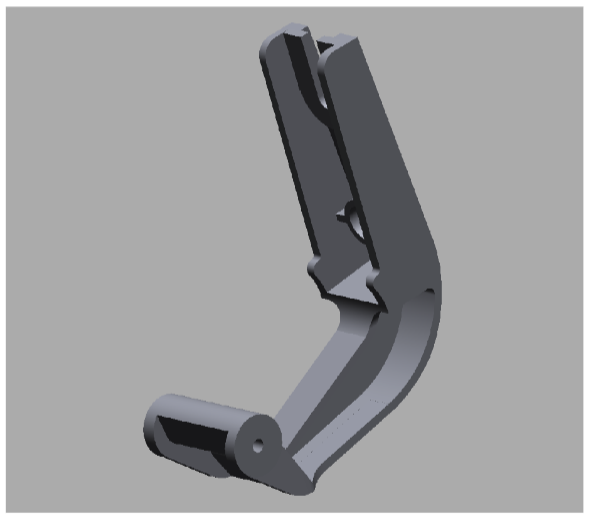

We use our laser scanner to capture all of the necessary detail of the hinge.

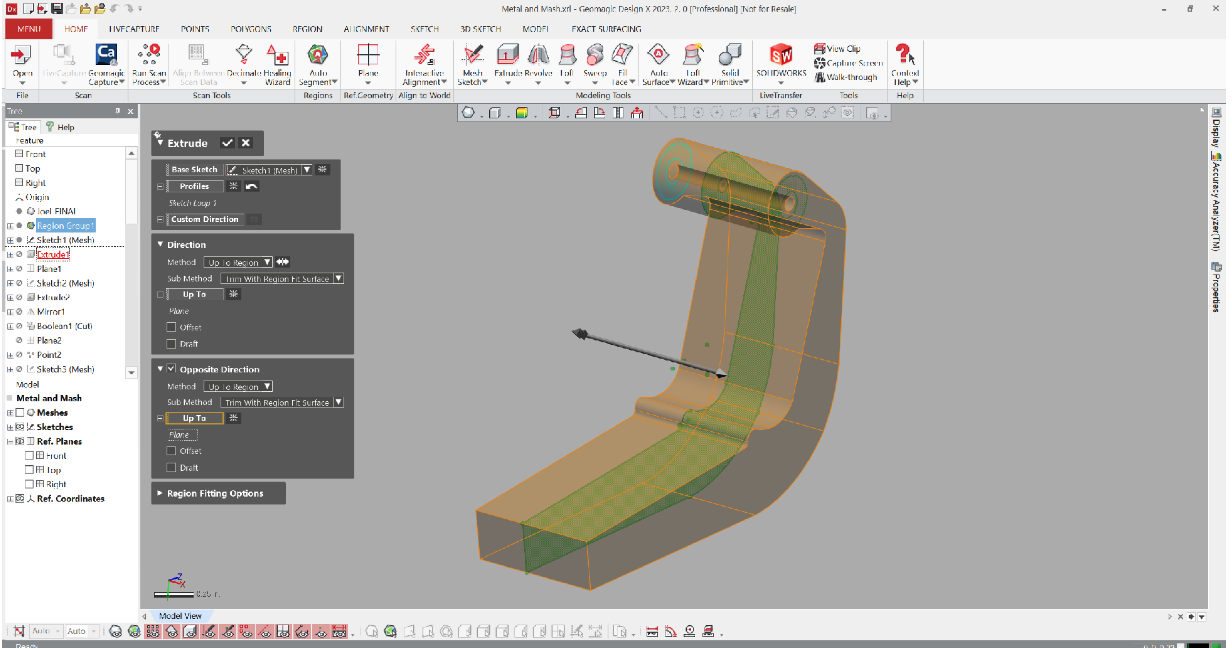

Step 2 – Reverse Engineer from the scan to a mechanical CAD model

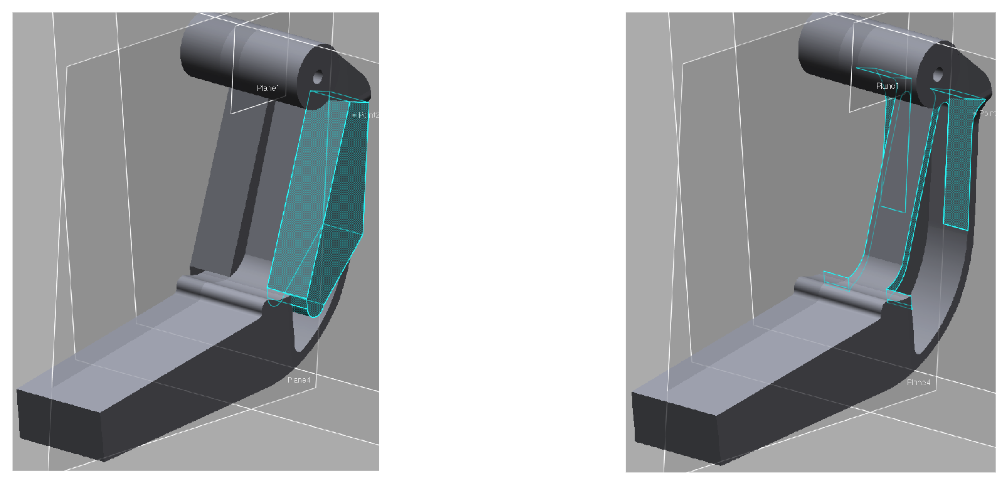

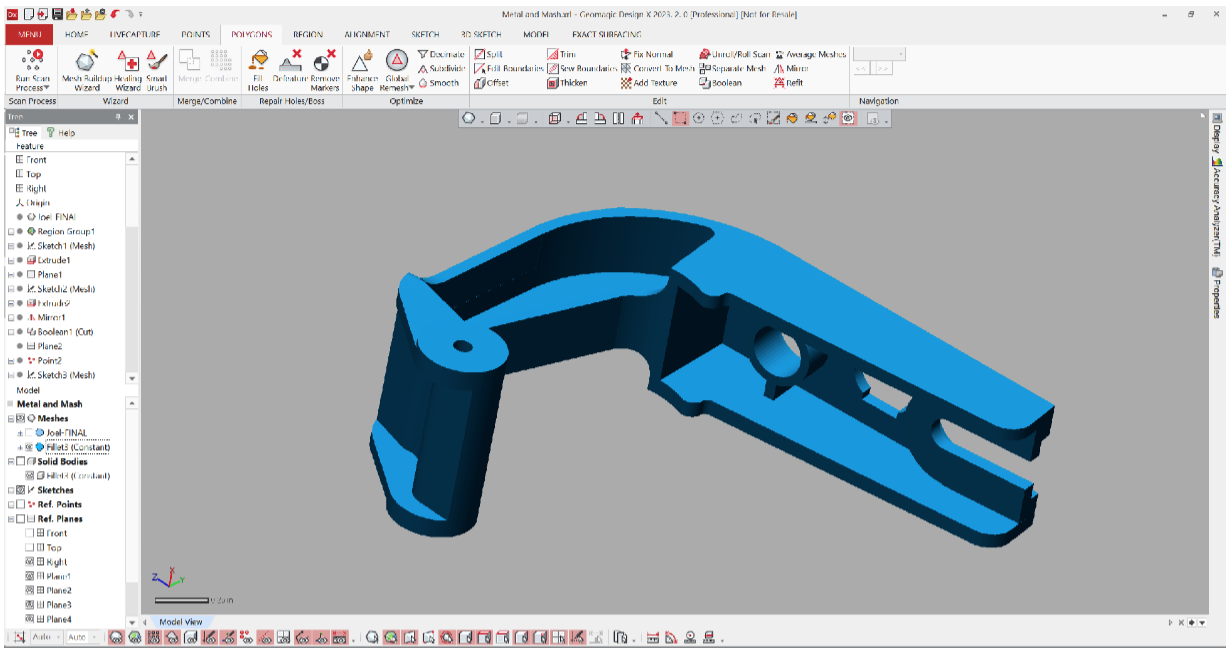

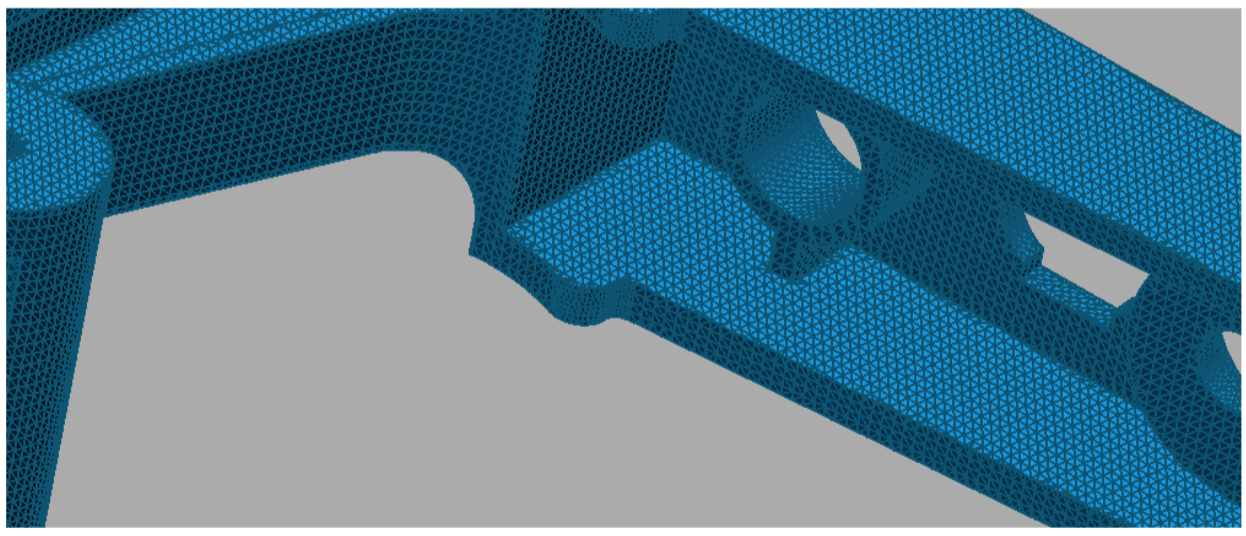

We import the scan into Design X reverse engineering software and step our way through the modeling of the bracket based upon the scan features captured from the broken bracket.

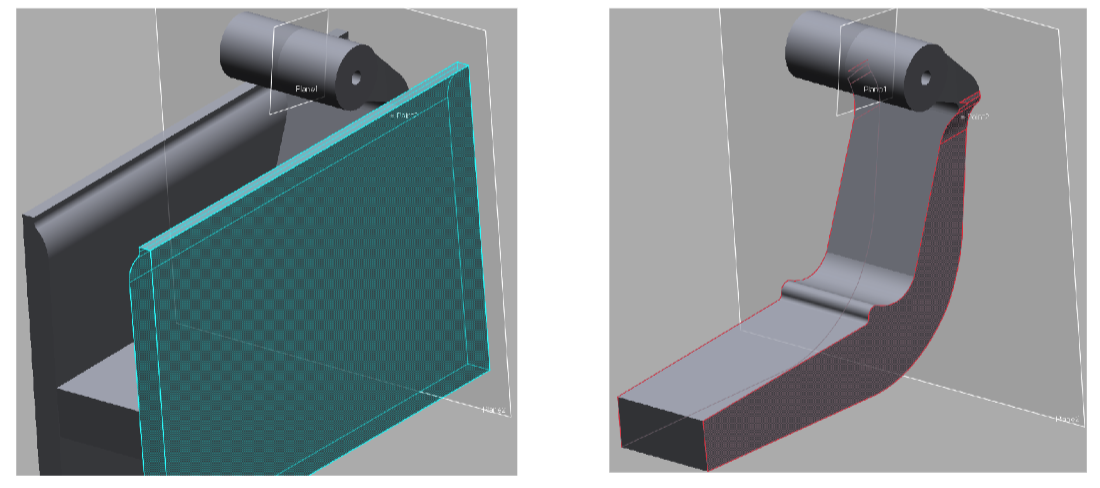

After the initial Extrusion, we continue modeling the bracket, taking advantage of symmetry as we go.

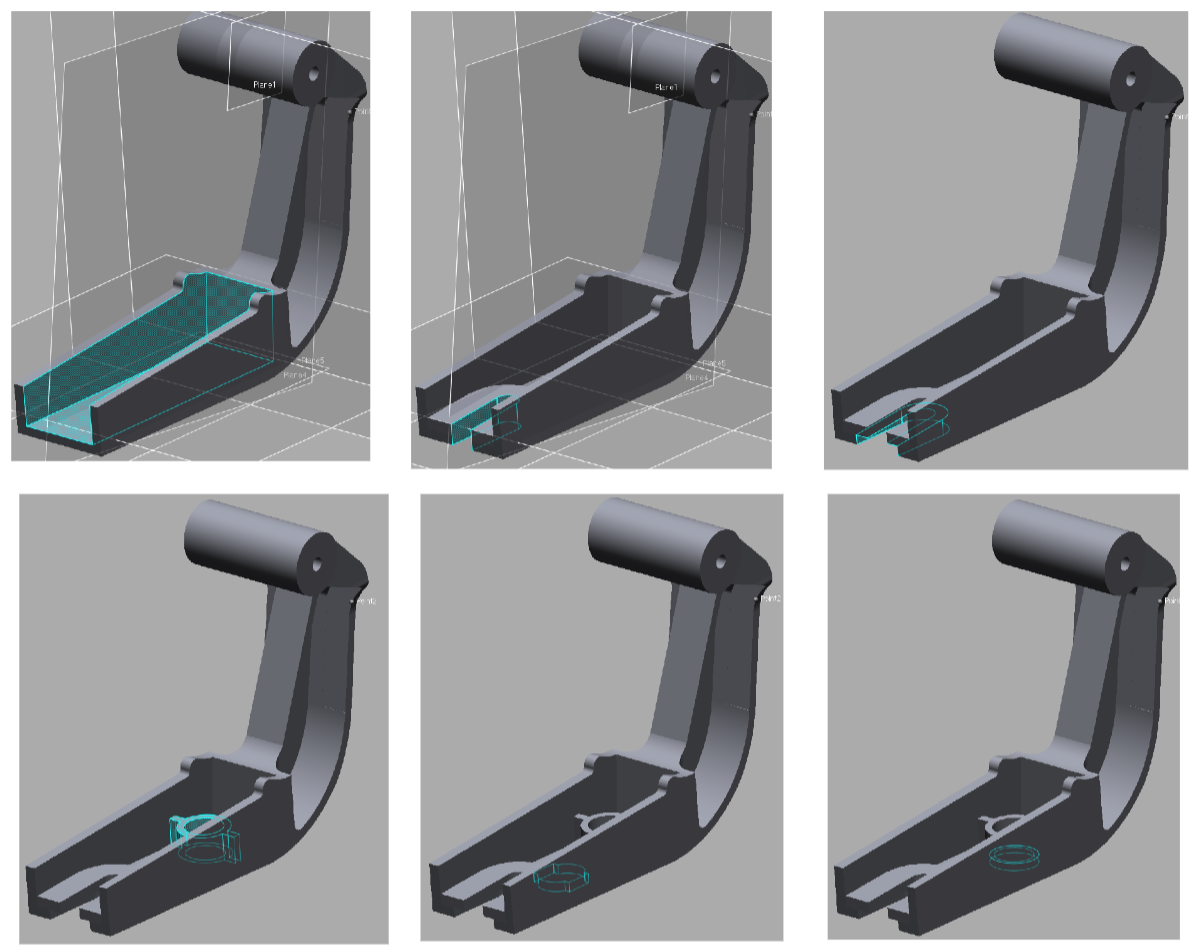

Adding the Small Pocket to the Extruded shape

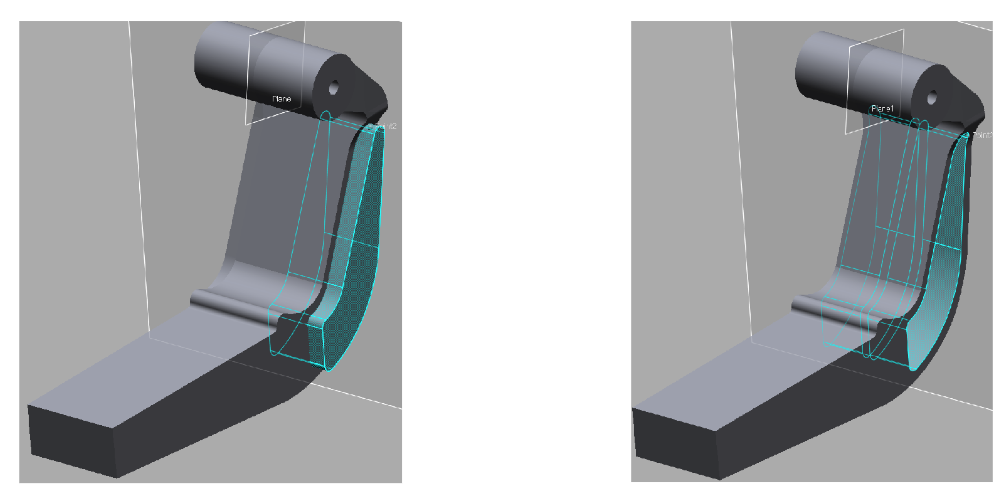

Cutting away excess material on the front and back of the model

Subtracting the two pockets from the shape

Subtracting the two pockets from the shape

Reducing the height of the inner rib to match the scan

Removing the large pocket material and inserting the bottom cutouts and ribs

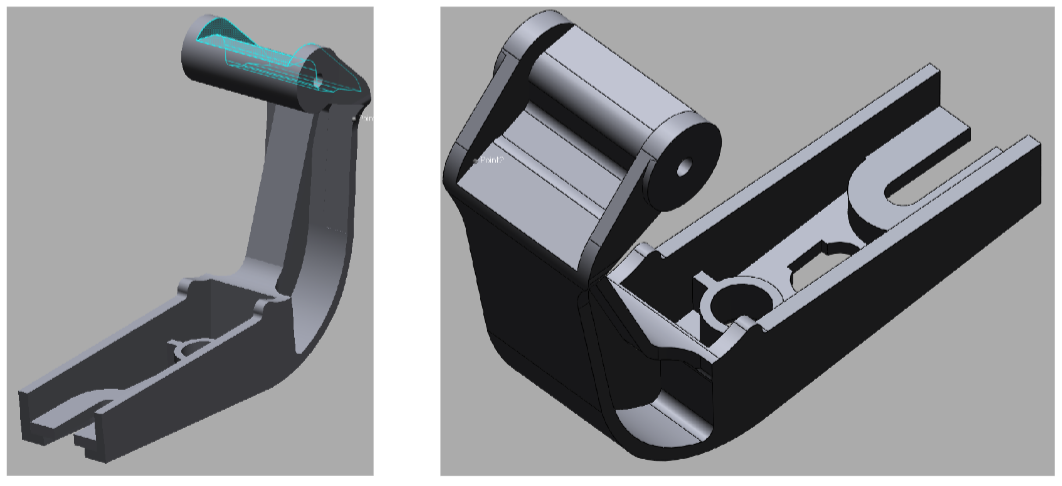

Cutting in the top detail to complete the hinge design

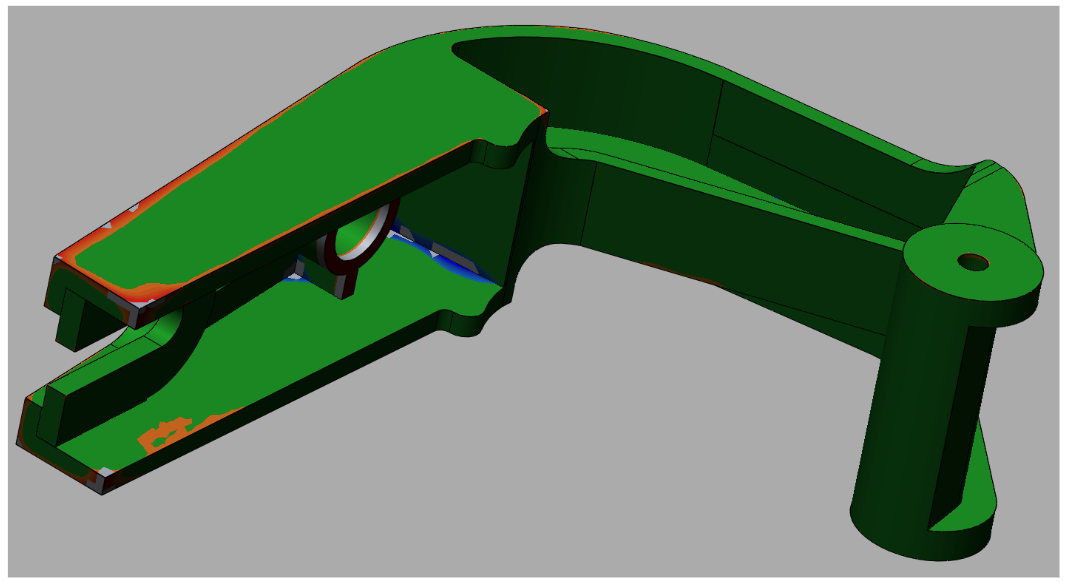

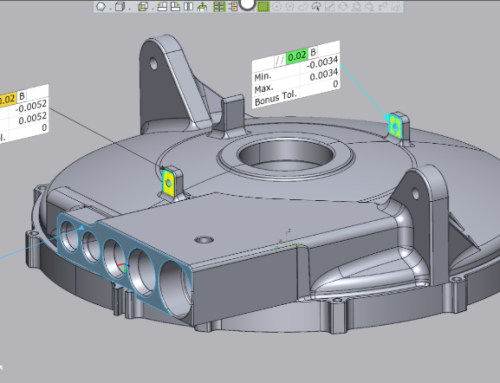

Confirming that we have what we think we have, we can use a deviation analysis color map in Design X to compare our derived solid model to the original scan data to ensure data integrity. Looks like an excellent match! We can see some of the worn areas highlighted by the color map.

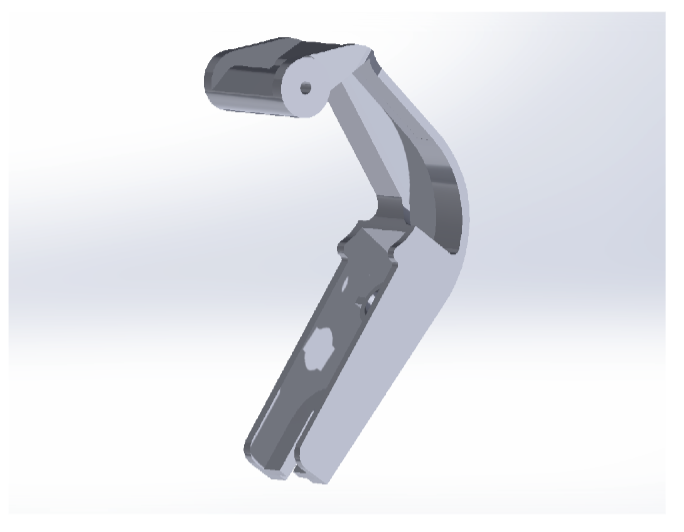

At this point, we have a fully native CAD model that we can import into a host of CAD software products for further design modifications or we can export as a mesh and send to a metal 3D Printer to complete the task of Printing a replacement hinge.

Step 3 – Metal Print a replacement hinge

Broken hinge

Reverse engineering Hinge Replacement

After metal printing, we now have a replacement hinge so rather than replacing all of the kitchen cabinets, we can fix the single door and we’re good to go, until the next thing breaks, of course!

For more information on 3D scanning and Reverse Engineering, please click below.

Leave A Comment