by Harry Foxman – a reprint from https://www.fabbaloo.com/news/lessons-from-cimquests-2021-xpand3d-event-part-one

What to look for in selecting a 3D Scanner

Over the past three decades, scanning technology has advanced immensely. It is now a helpful tool to be used in reverse engineering, inspection, and 3D printing. With a large number of different types of scanners from a variety of manufacturers on the market today, it is important that a company selects the correct one. Before beginning the search for a scanner, companies should have predetermined criteria mapped out.

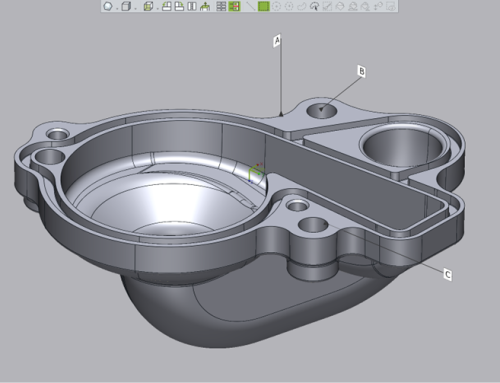

In order to narrow down the vast field of scanners on the market, there are several different steps to consider guiding you in the right direction. The first step is to determine what sizes of parts you want to scan. Are the parts large or small, mechanical or organic? For example, scanning a part to be used in a machine would require a drastically different scanner than scanning a feature on a body. The application of what is scanned also needs to be considered. An item can be scanned for a variety of reasons including reverse engineering, metrology, 3D printing, web content, and virtual reality. Additional software processing costs are also something that needs to be considered as scanners have specific software that they convey data through.

Accuracy and resolution are important aspects when determining what type of scanner. Accuracy in a scanner is how exact the scanning measurements are in a plus/minus sense compared to the actual object. Resolution refers to how well the scanner picks up fine detail in a part. Most scanners on the market have published resolutions. If accuracy is important for your application, make sure the scanner that is purchased has a published accuracy.

Repeatability is the ability of a scanner to repeat results when an item is scanned by a different person or a different technique. The deviation tolerances between repeated scans should be minimal. Color is another specification when considering what scanner to purchase for your company. Color can be a tricky aspect of scanning as sometimes a color scan can hide poor resolution. Texture needs to be turned off to reveal the poor resolution. In 3D printing, color is especially important when you have a color 3D printer and want to scan 3D parts in color.

Leave A Comment